cutmaster 102

INSTALLATION 3-6 Manual 0-4998

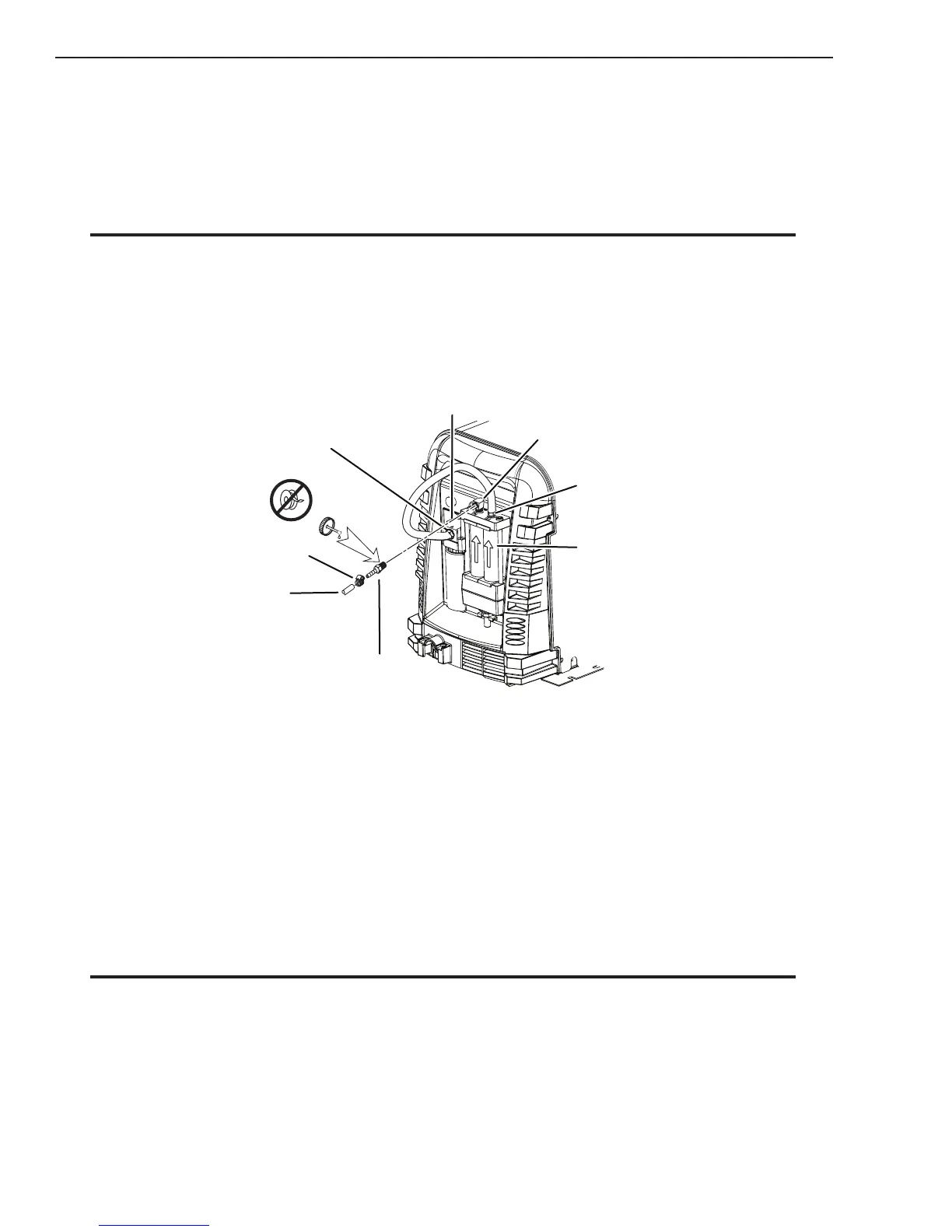

Installing Optional Two - Stage Air Filter Kit

This optional two - stage air line lter is also for use on compressed air shop systems. Filter removes

moisture and contaminants to at least 5 microns.

Connect the air supply as follows:

1. Attach the Two Stage Filter bracket to the back of the power supply per instructions supplied

with the lter assembly.

NOTE

For a secure seal, apply Permatex PX56521 or equivalent thread sealant to the fitting threads, according to the

manufacturer’s instructions. Do not use Teflon tape as a thread sealer, as small particles of the tape may break off

and block the small air passages in the torch.

2. Connect the two stage lter outlet hose to the inlet port of the Regulator / Filter Assembly.

3. Use customer - supplied ttings to connect the air line to the Filter. A 1/4 NPT to 1/4" hose

barbed tting is shown as an example.

Art # A-07945_AB

Regulator/Filter

Assembly

Regulator

Input

2-Stage Filter

Inlet Port (IN)

Outlet Port

(OUT)

Two Stage

Filter

Assembly

Gas Supply

Hose

1/4 NPT to 1/4”

(6mm) Fitting

Optional Two - Stage Filter Installation

Using High Pressure Air Cylinders

When using high pressure air cylinders as the air supply:

1. Refer to the manufacturer’s specications for installation and maintenance procedures for high

pressure regulators.

2. Examine the cylinder valves to be sure they are clean and free of oil, grease or any foreign mate-

rial. Briey open each cylinder valve to blow out any dust which may be present.

3. The cylinder must be equipped with an adjustable high - pressure regulator capable of outlet

pressures up to 100 psi (6.9 bar) maximum and ows of at least 300 scfh (141.5 lpm).

4. Connect supply hose to the regulator.

NOTE

Pressure should be set at 100 psi (6.9 bar) at the high pressure cylinder regulator.

Supply hose must be at least 1/4 inch (6 mm) I.D.

For a secure seal, apply Permatex PX56521 or equivalent thread sealant to the fitting threads, according to man-

ufacturer's instructions. Do Not use Teflon tape as a thread sealer, as small particles of the tape may break off and

block the small air passages in the torch.

Loading...

Loading...