cutmaster 102

Manual 0-4998 5-9 SERVICE

If all of the Pre Power-Up Tests are ok, proceed with

the trouble shooting guide.

CAUTION

Due to the close proximity of the Main Pcb to the

Capacitor Pcb, It is recommended to use an insu-

lated meter probe when making measurements on

the J2 connector on the Main Pcb. Do not short

between the pins. Do not short to the Capacitor

Pcb connections.

D. Initial Set up Conditions

This section is to help isolate the defective circuit

before troubleshooting, identify symptoms, and test

the unit for proper operation. Follow the instructions

as given to identify the possible symptom(s) and the

defective circuit. After repairs are complete, run the

following tests again to verify that the unit is fully

operational.

1. Connect gas supply to rear of Power Supply.

2. Turn on gas supply and set operating pressure

per pressure setting label on power supply.

3. Set the Power Supply controls as follows:

• ON/OFF SWITCH to OFF position

• Turn FUNCTION CONTROL SWITCH to SET

position

• CURRENT CONTROL POTENTIOMETER to

MAXIMUM position, fully clockwise.

E. Main Input and Internal Power Test

1. Connect Primary Line power to the unit.

2. Turn the ON/OFF SWITCH ( SW1) to ON position

and observe the following:

• Software version is displayed (See section 5.04

Fault Indicators)

After approx. three (3) seconds

• Inrush relay on PCB1 energizes, starting pre-

charging of working capacitors.

• W1 energizes

• AC and GAS Indicators come on

• Gas flows

• For earlier units, Fan MOT1 turns on for one

(1) second then shuts off.

3. Adjust the pressure regulator to set the gas pres-

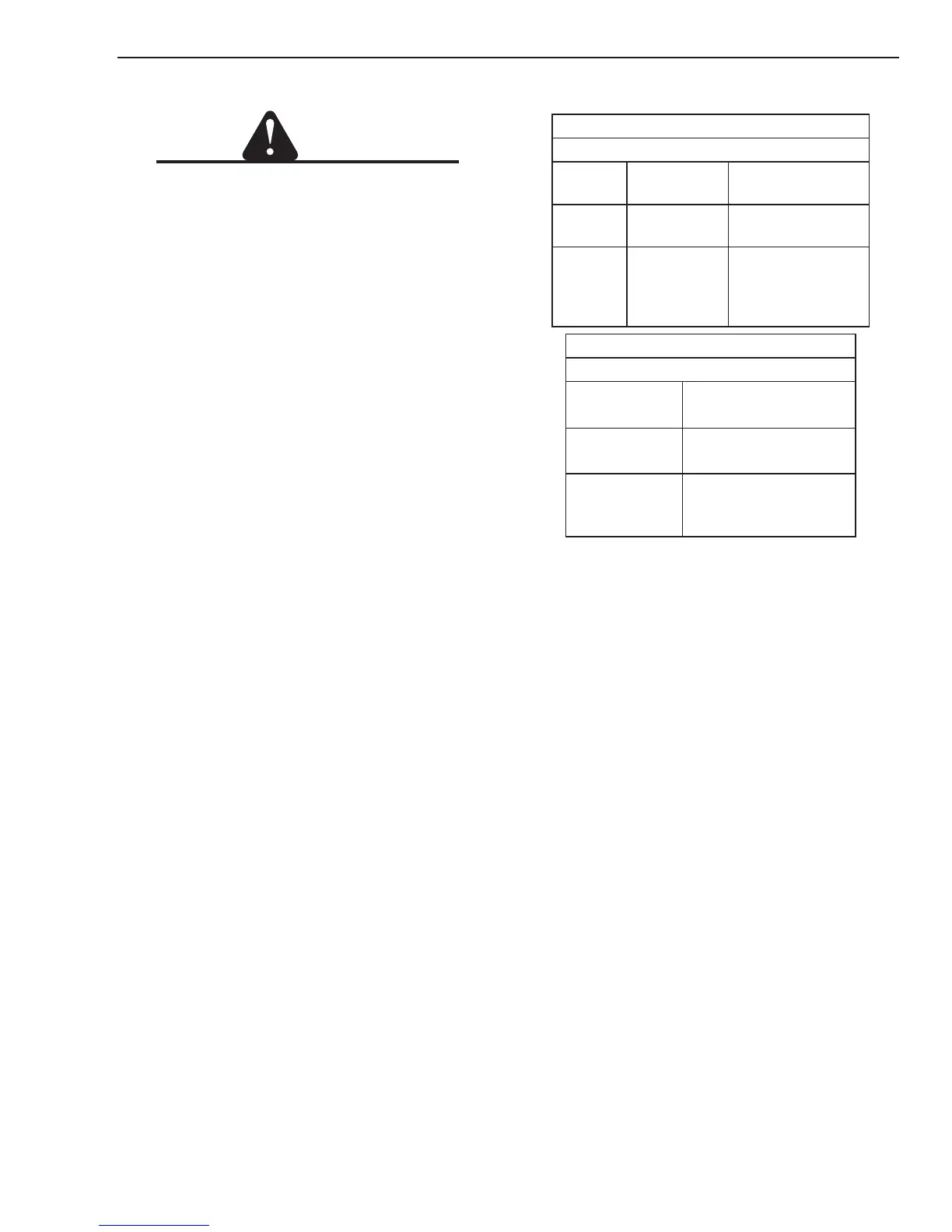

sure as specified in charts.

STANDOFF

CutMaster 102 Gas Pressure Settings

Leads

Length

SL100

(Hand Torch)

SL100

(Mechanized Torch)

Up to 25'

(7.6 m)

75 psi

5.2 bar

75 psi

5.2 bar

Each

additional

25'

(7.6 m)

Add 5 psi

0.4 bar

Add 5 psi

0.4 bar

DRAG

CutMaster 102 Gas Pressure Settings

Leads

Length

SL100

(Mechanized Torch)

Up to 25'

(7.6 m)

80 psi

5.5 bar

Each additional

25'

(7.6 m)

Add 5 psi

0.4 bar

4. Turn FUNCTION CONTROL SWITCH to RUN

position

• Solenoid turns off, gas stops flowing (pressure

display may increase slightly when gas is not

flowing)

This completes the Main Input and Internal Power Test.

If the above are all correct then proceed to the next section

"F. Pilot Arc Test". If the unit does not function as stated

above, then note the symptom and proceed to Section

"5.07, Main Input and Internal Power Problems".

Loading...

Loading...