CUTMASTER 58

Manual 0-5544 SERVICE

5T-1

SECTION 5 TORCH:

SERVICE

5T.01 General Maintenance

NOTE!

Refer to Previous “Section 5: System” for common

and fault indicator descriptions.

Cleaning Torch

Even if precautions are taken to use only clean air with a

torch, eventually the inside of the torch becomes coated

with residue. This buildup can aect the pilot arc initia-

tion and the overall cut quality of the torch.

WARNING

Disconnect primary power to the system before

disassembling the torch or torch leads.

DO NOT touch any internal torch parts while the AC

indicator light of the Power Supply is ON.

The inside of the torch should be cleaned with electrical

contact cleaner using a cotton swab or soft wet rag. In

severe cases, the torch can be removed from the leads

and cleaned more thoroughly by pouring electrical

contact cleaner into the torch and blowing it through

with compressed air.

!

CAUTION

Dry the torch thoroughly before reinstalling.

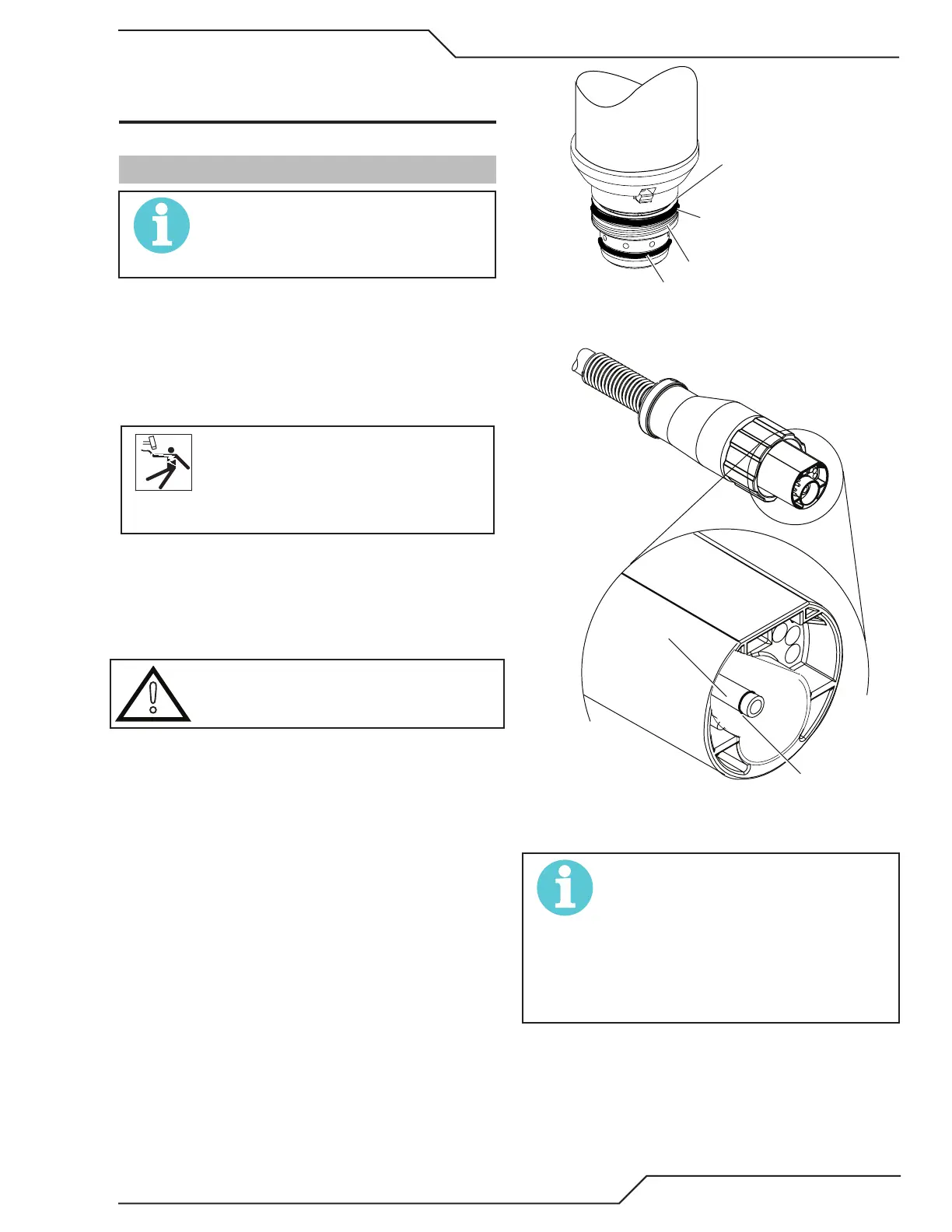

O-Ring Lubrication

An O-Ring on the Torch Head and ATC Male Connector

requires lubrication on a scheduled basis. This will allow

the O-Rings to remain pliable and provide a proper seal.

The O-Rings will dry out, becoming hard and cracked

if the lubricant is not used on a regular basis. This can

lead to potential performance problems.

It is recommended to apply a very light lm of O-Ring

lubricant (Catalog # 8-4025) to the O-Rings on a weekly

basis.

Upper Groove

with Vent Holes

Threads

Upper O-Ring

in Correct Groove

Lower O-Ring

Art # A-03725

Torch Head O-Ring

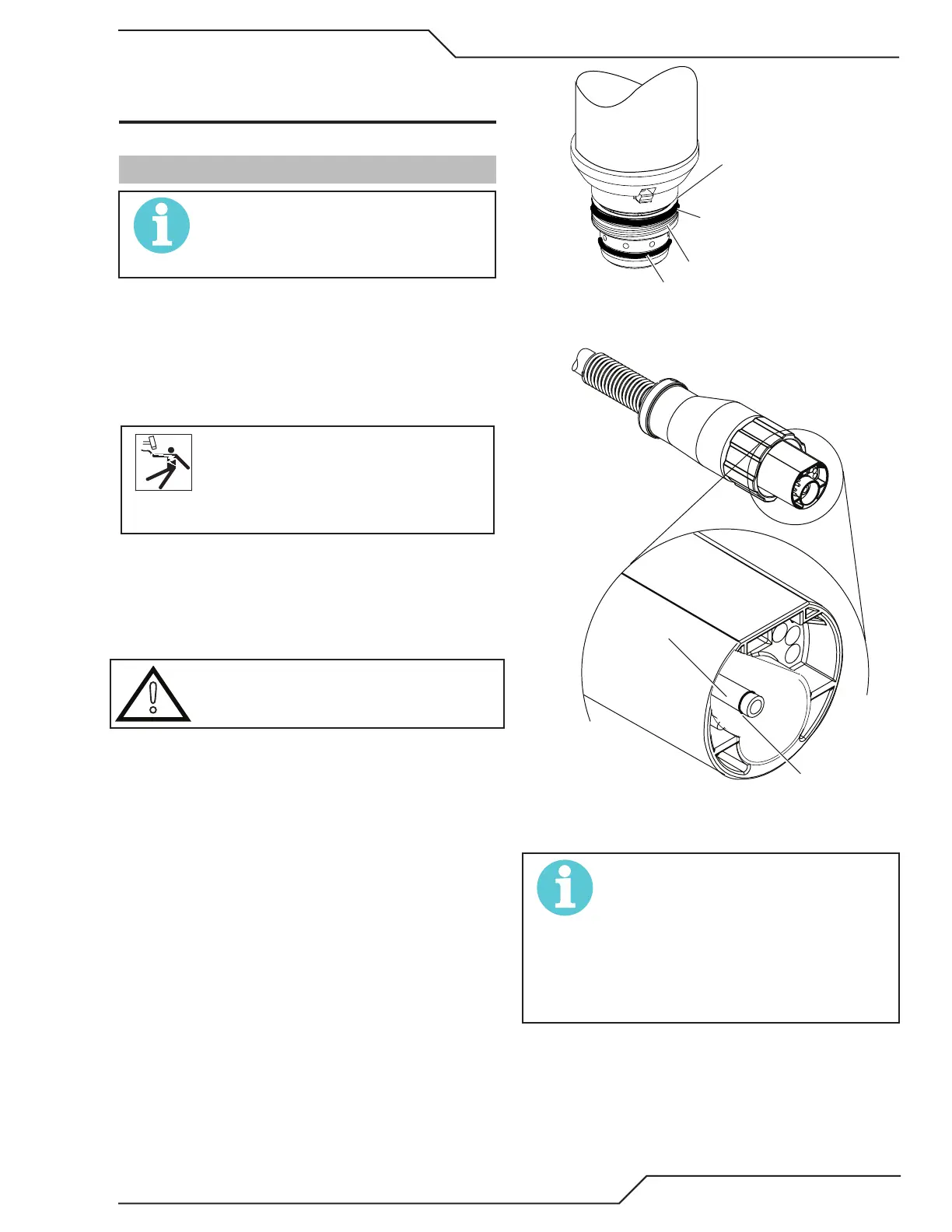

ATC Male Connector

Gas Fitting

O-Ring

ATC O-Ring

NOTE!

DO NOT use other lubricants or grease, they may not

be designed to operate within high temperatures

or may contain “unknown elements” that may react

with the atmosphere. This reaction can leave con-

taminants inside the torch. Either of these conditions

can lead to inconsistent performance or poor parts

life.

Loading...

Loading...