SERVICE TROUBLESHOOTING 28 Manual 0-2569

is greater than +4 vdc (and the TEMP indicator is

lit red), replace the LED PC board. If the voltage

at J3-4 is less than 4V, replace the Logic PC Board.

G. Pressure Sensing Circuits

The Merlin 6000 uses only a plasma gas pressure switch,

PS1, set for 35 psi (2.4 bar) and is located in the power

supply.

1. Check the dc voltage on the logic PCB from TP1

(ground) to J1-7. With the plasma gas pressure set

correctly (refer to Torch Manual for settings) and

the plasma gas flowing, the voltage should be less

than 1 vdc.

• If voltage is correct, proceed to next step.

• If voltage is incorrect, problem is open connec-

tion between Logic PCB and pressure switch,

faulty pressure switch or blockage in the gas

lines between the pressure gauge and pressure

switch (PS1).

2. Check dc voltage from TP1 (ground) to J3-3.

• If voltage is greater than 12 vdc replace the Logic

PCB.

• If voltage is less than 12 vdc, replace the LED

and Current Control PCB or the ribbon cable.

H. Gas Solenoid Circuits

The Merlin 6000 has three groups of solenoids located on

the Rear Panel of the Merlin 6000 Power Supply. Listed

below are their reference designator, function and coil re-

sistance.

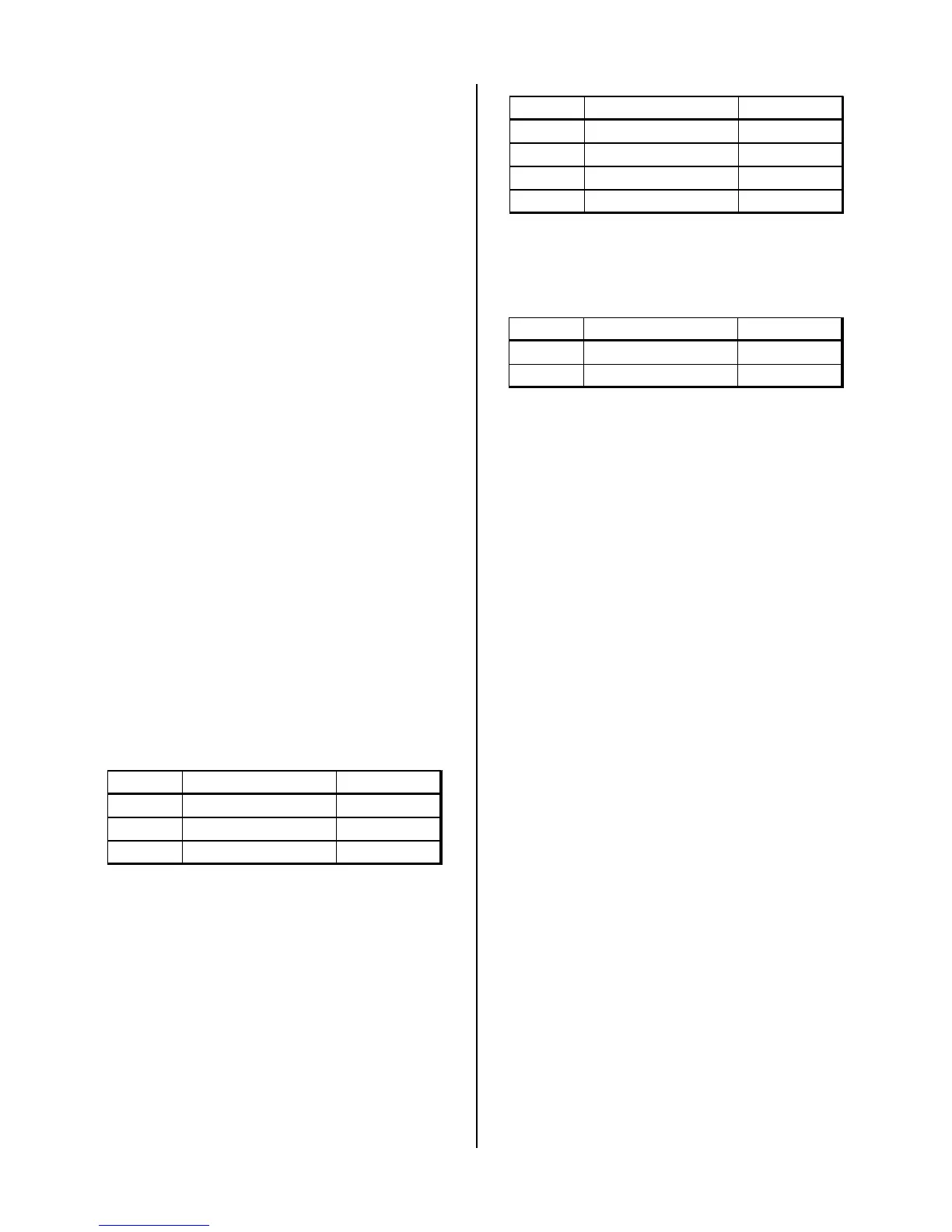

1. Standard Gas Select Solenoids

Solenoid Description Ohms (Approx.)

SOL1 Plasma 375

SOL2 Secondary 375

SOL3 Secondary Water 375

SOL1 is on when any gas set mode is selected (Plasma

or Secondary Set).

SOL2 is on for Secondary Set Mode .

During cutting, both SOL1 & SOL2 are on from Start

to the end of Post-flow (Pre-flow, Pilot, Cut & Post-

flow).

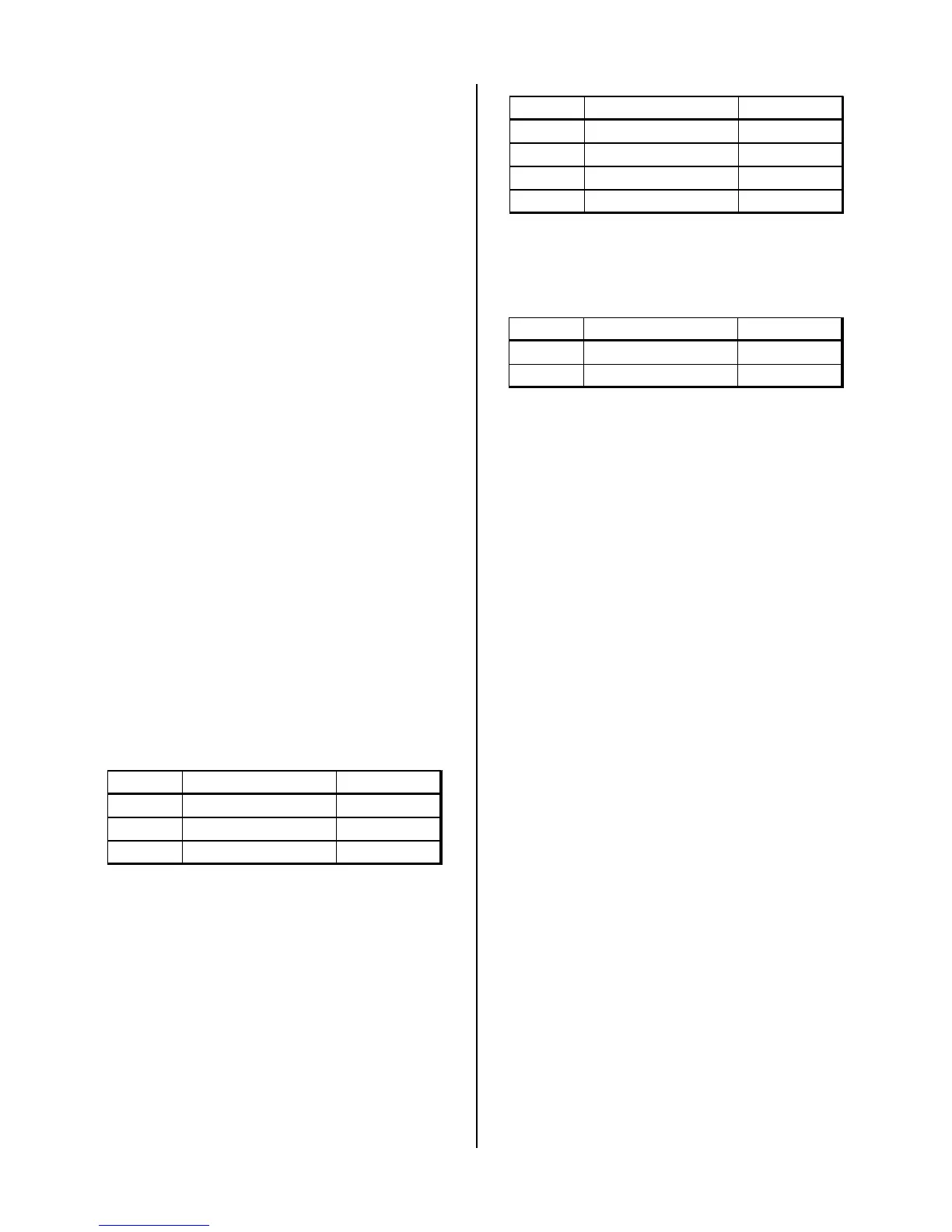

2. Optional Plasma Gas Select Solenoids

Solenoid Description Ohms (Approx.)

SOL4 Air Plasma 300

SOL5 Nitrogen Plasma 300

SOL6 Oxygen Plasma 300

SOL7 Argon/Hydrogen Plasma 300

Normal operation is for one plasma gas solenoid to

be ON when ever the power supply is ON.

3. Optional Secondary Gas Solenoids

Solenoid Description Ohms (Approx.)

SOL8 Nitrogen Secondary 300

SOL9 Other Secondary 300

Normal operation is for one secondary gas solenoid

to be ON when ever the power supply is ON.

For the following tests refer to Appendix XVI, Power Sup-

ply Plumbing Diagram and either Appendix XXIII or

XXIV, System Schematics.

• Plasma Gas Problems Without Optional Gas

Control (GC3000)

Plasma gas passes through the plasma gas solenoid

(SOL1) at the rear panel of the power supply. Low or

no pressure on the Plasma Pressure Gauge can indi-

cate a problem with the plasma gas solenoid, regula-

tor, clogged torch head and leads or the gas supply.

Low or no flow of plasma gas in SET Mode. Make the

following checks:

a. Check that the incoming plasma gas pressure is

correct.

b. With power removed from the power supply re-

move the plasma gas connection at the power sup-

ply bulkhead. Turn ON the power supply and set

the RUN/PURGE/SET switch to the SET position.

If there is a strong gas flow the torch head or leads

are clogged. If there is a weak or no gas flow the

solenoid is faulty.

c. Measure the plasma gas solenoid (SOL1) coil re-

sistance, if it’s not about 375 ohms replace the so-

lenoid. If resistance is correct measure for 120 VAC

across the solenoid coil, if correct the plunger is

stuck, replace the solenoid.

d. If there is no voltage, use Appendix XXIII or XXIV,

System Schematics, to troubleshoot.

SOL1 is controlled from the plasma relay, K4, on

the Logic PCB. To test for a bad Logic PCB, mea-

sure for 120 VAC between wire #9 on the ON/

OFF switch (SW1) and J2-3. If no voltage is there,

Loading...

Loading...