Manual 0-2470 35 OPERATION

4.06 OPERATING THE SYSTEM (continued)

Dross

(continued)

High speed dross usually forms a narrow bead along the bottom

of the cut edge and is very difficult to remove. When cutting a

troublesome steel, it is sometimes useful to reduce the cutting

speed to produce slow speed dross. Any resultant cleanup can be

accomplished by scraping, not grinding.

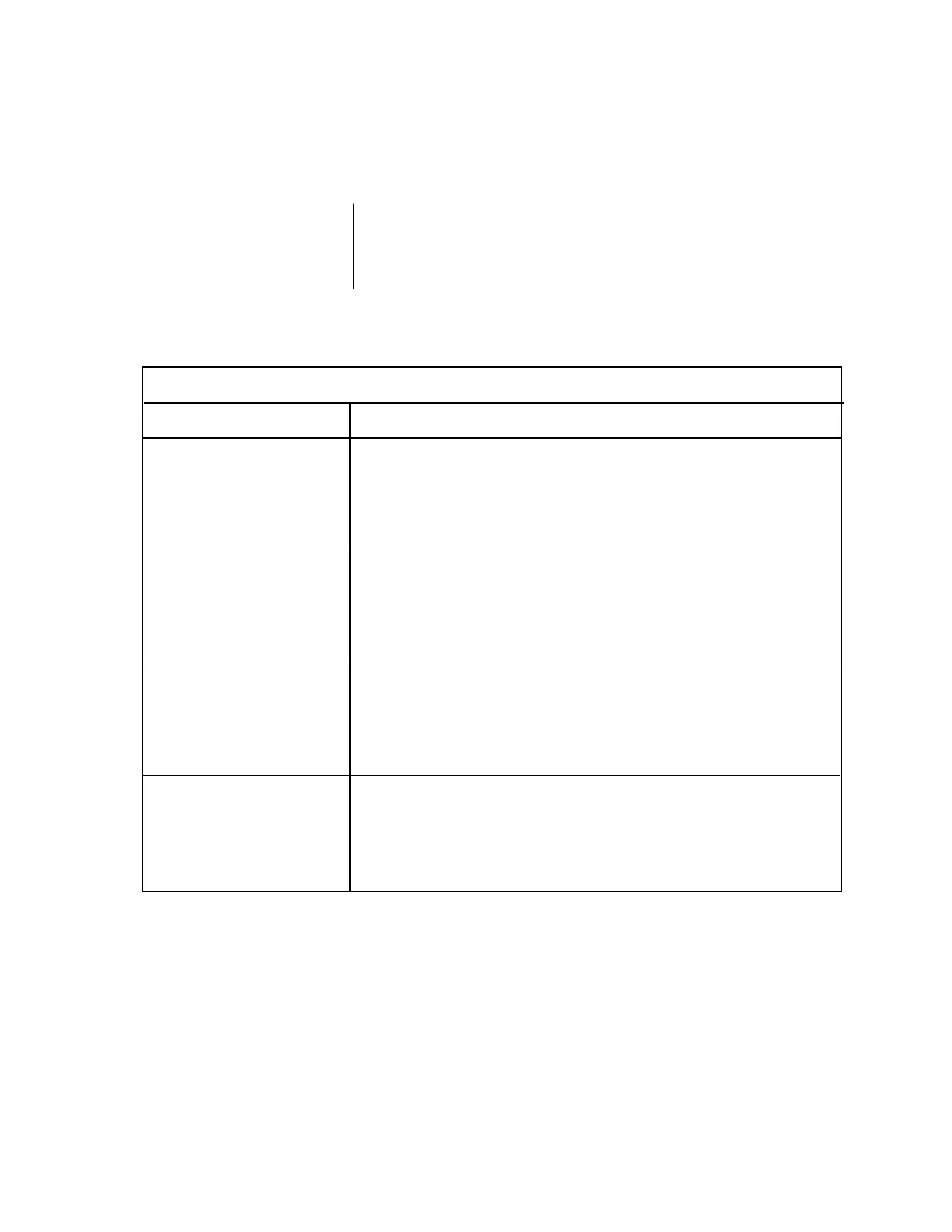

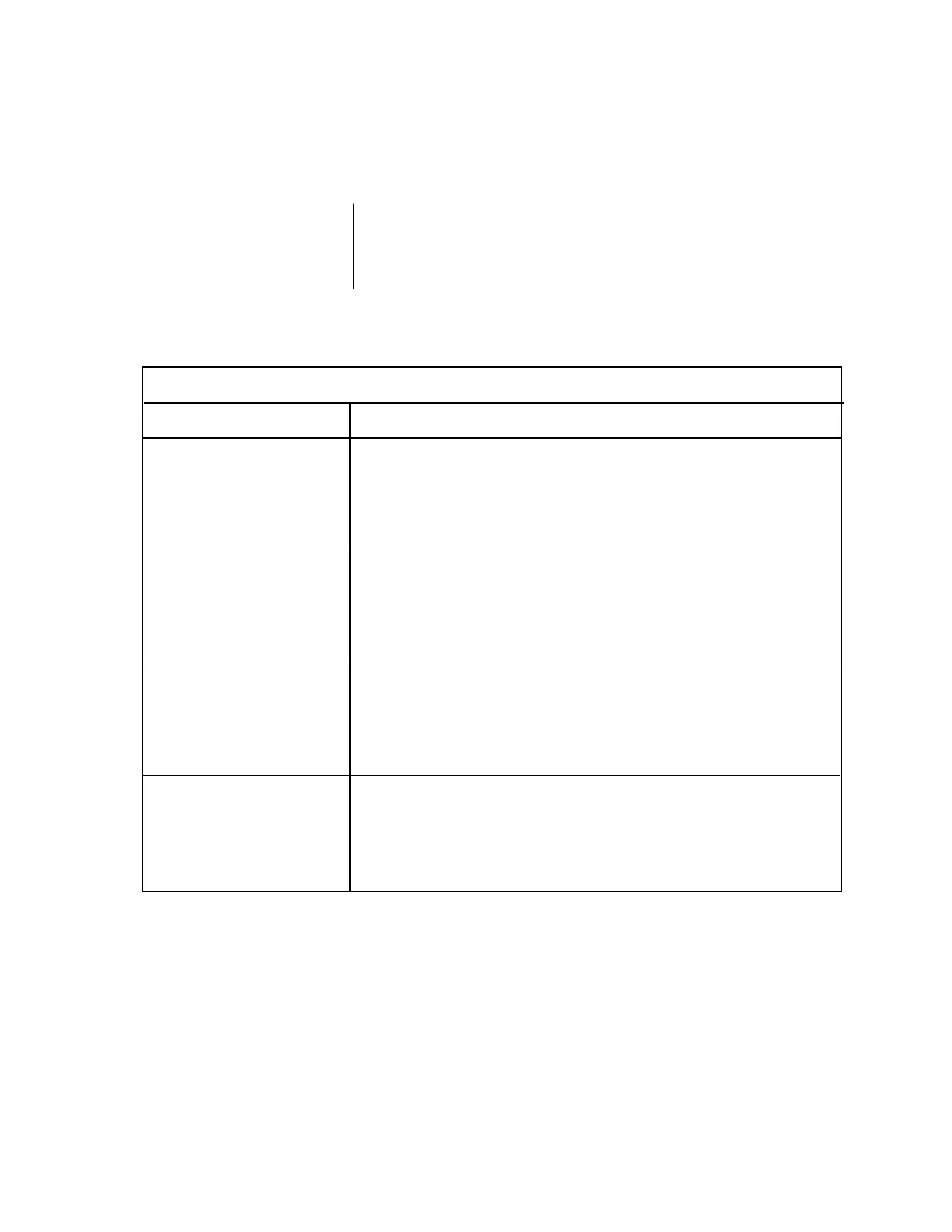

Table 4-C Common Causes of Operating Problems

Problem

Insufficient

Penetration

Main Arc

Extinguishes

Excessive

Dross Formation

Short Torch

Parts Life

Possible Cause

1. Cutting speed too fast

2. Torch tilted too much

3. Metal too thick

4. Worn torch parts

5. Cutting current too low

1. Cutting speed too slow

2. Torch standoff too high from workpiece

3. AC line too low - reduce output current

4. Work cable disconnected

5. Worn torch parts

1. Cutting speed too slow (bottom dross) Easily removed

2. Cutting speed too fast (bottom dross) Tight bead, Difficult to remove

3. Torch standoff too high from workpiece (top dross) Easily removed

4. Worn torch parts

5. Improper cutting current

1. Oil or moisture in air source

2. Exceeding system capability (material too thick)

3. Excessive pilot arc time

4. Air flow too low (incorrect pressure)

5. Improperly assembled torch

Common Cutting Faults

Loading...

Loading...