Removal

1 Remove any attachment and lower the boom arms.

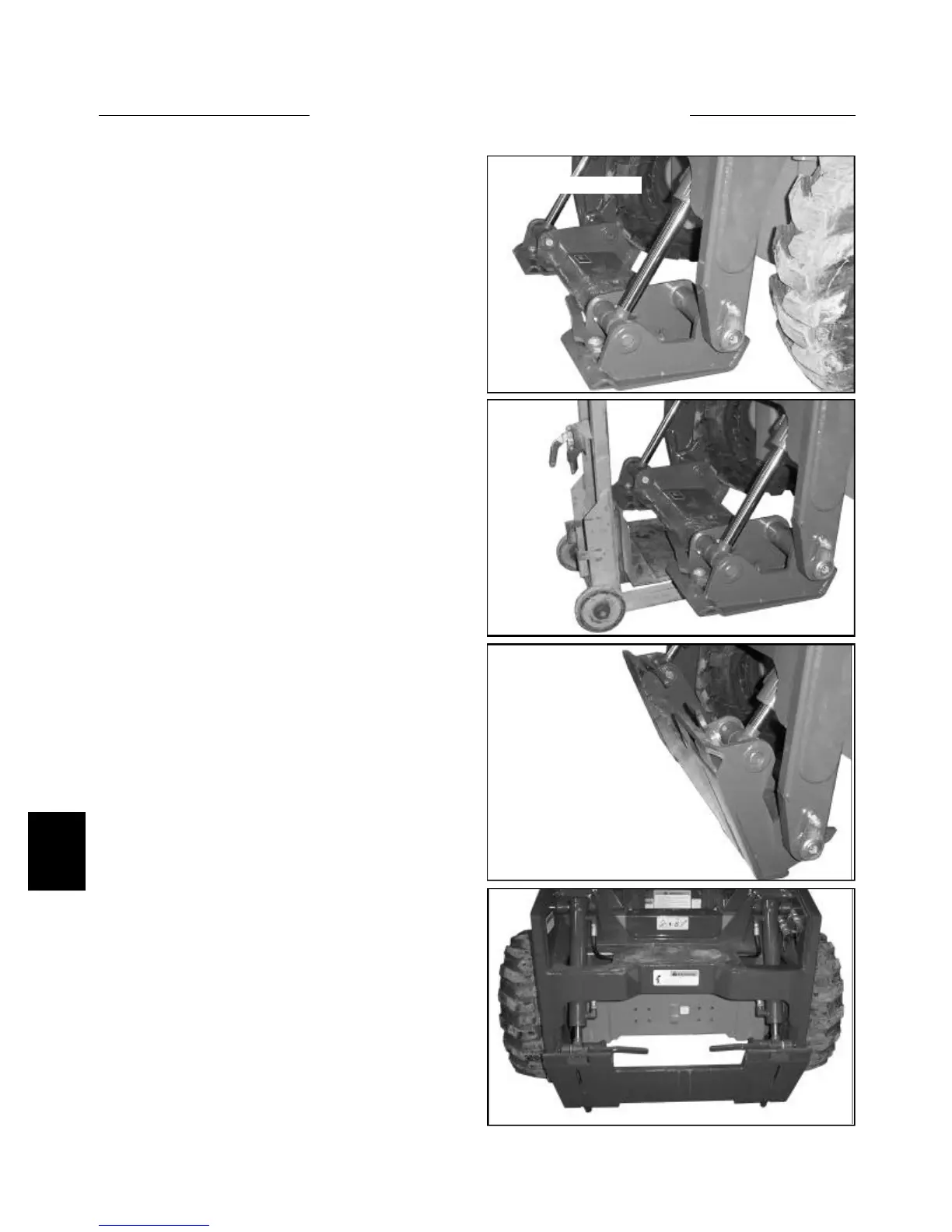

2 Start the engine and extend the hydraulic tilt cylin-

ders approximately 12 inches. (fig. C3880)

3 Shut off the engine and engage the parking brake.

4 Remove the bolts retaining the upper pivot pins to

the quick - tach frame until the quick-tach is level and the

pins removed. (fig. C3880)

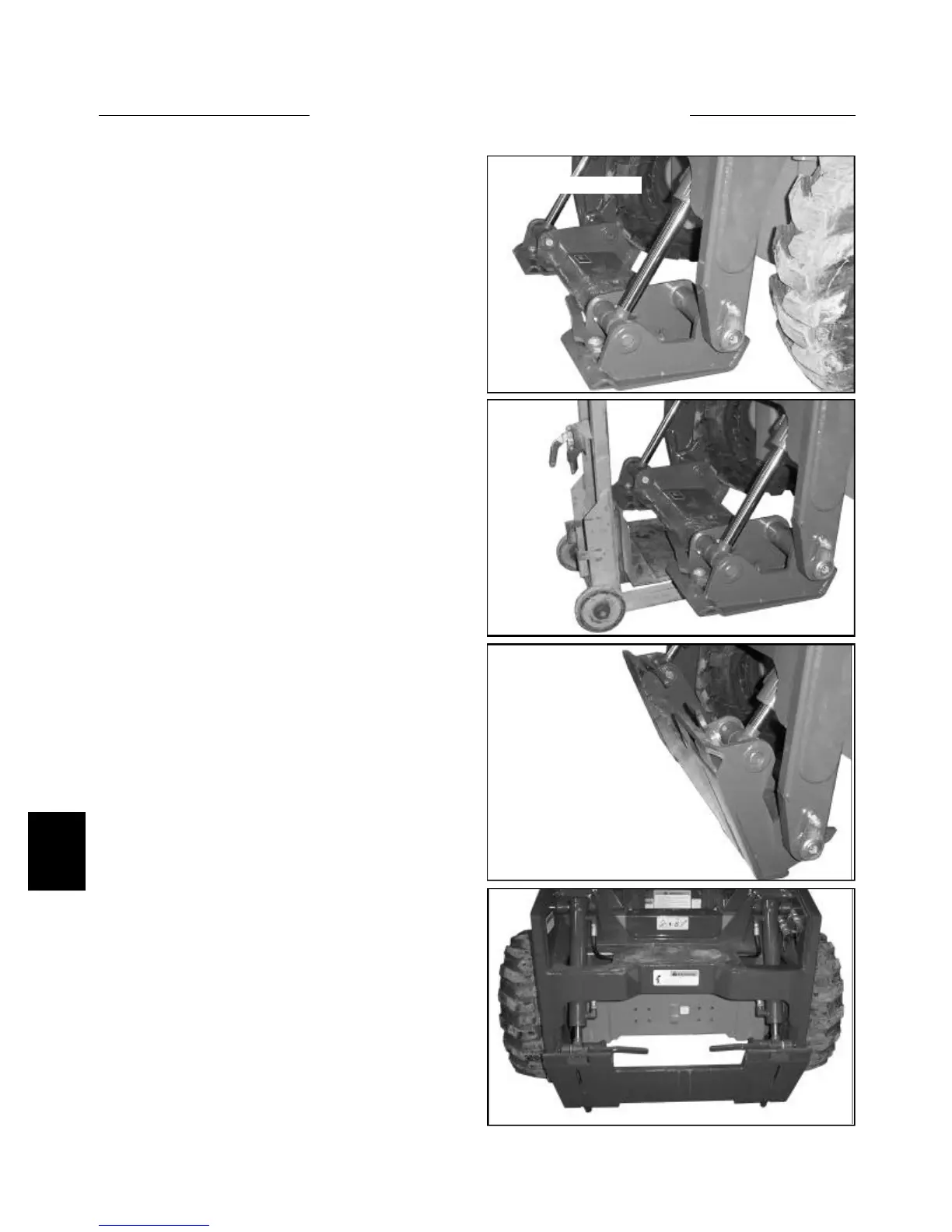

5 If this repair is being performed in a proper work

shop, a portable floor jack works excellent for this next

step. Place the floor jack under the quick - tach.

(fig. C3881)

6 The floor jack is used to relieve the weight on the 2

(two) lower pivot pins. Remove the upper pivot pins.

7 Remove the nuts and or bolts retaining the 2 (two)

lower quick - tach pivot pins to the quick - tack or boom

arms. (There are two different types). (fig. C3882)

8 Remove the pivot pins using a brass drift punch and

hammer.

9 Remove the quick - tach from the loader boom arms.

6-4

C3880

C3883

C3882

C3881

Extend tilt cylinders

Installation

Upon installing the quick - tach to the loader boom arms:

1 Make sure all pivot pins and bushings are in good

condition. Do not reuse worn parts. Replace pins and

hardened bushings as required.

2 Use the floor jack to assist installing the quick - tach

to the loader boom arms. (Or lay it down on a piece of

wood. (fig. C3881)

3 Raise the bottom of the quick - tach up to align the

boom arm pivot holes and the lower quick - tach pivot

bushings. Install the 2 lower pivot pins, retaining bolts

and or lock nuts.

4 Align the 2 tilt cylinder pivot bushings with the quick

- tach bushings and install the pins and retaining bolts and

lock nuts.

5 Lubricate all pivots until excess grease can be seen

flowing out around the bushings and pins.

QUICK - TACH 6.1

Loading...

Loading...