4-7

Tracking Adjustment (Speed)

Tracking adjustment, or wheel speed, is set individually

for L.H. and R.H. sides. If the operator complains the

loader does not go in a straight line when the levers are

pushed clear forward the limiter stops may need adjust-

ment.

1 Raise the boom arms, engage the boom support pins

and shut off the engine. Raise and block the loader

securely off the ground.

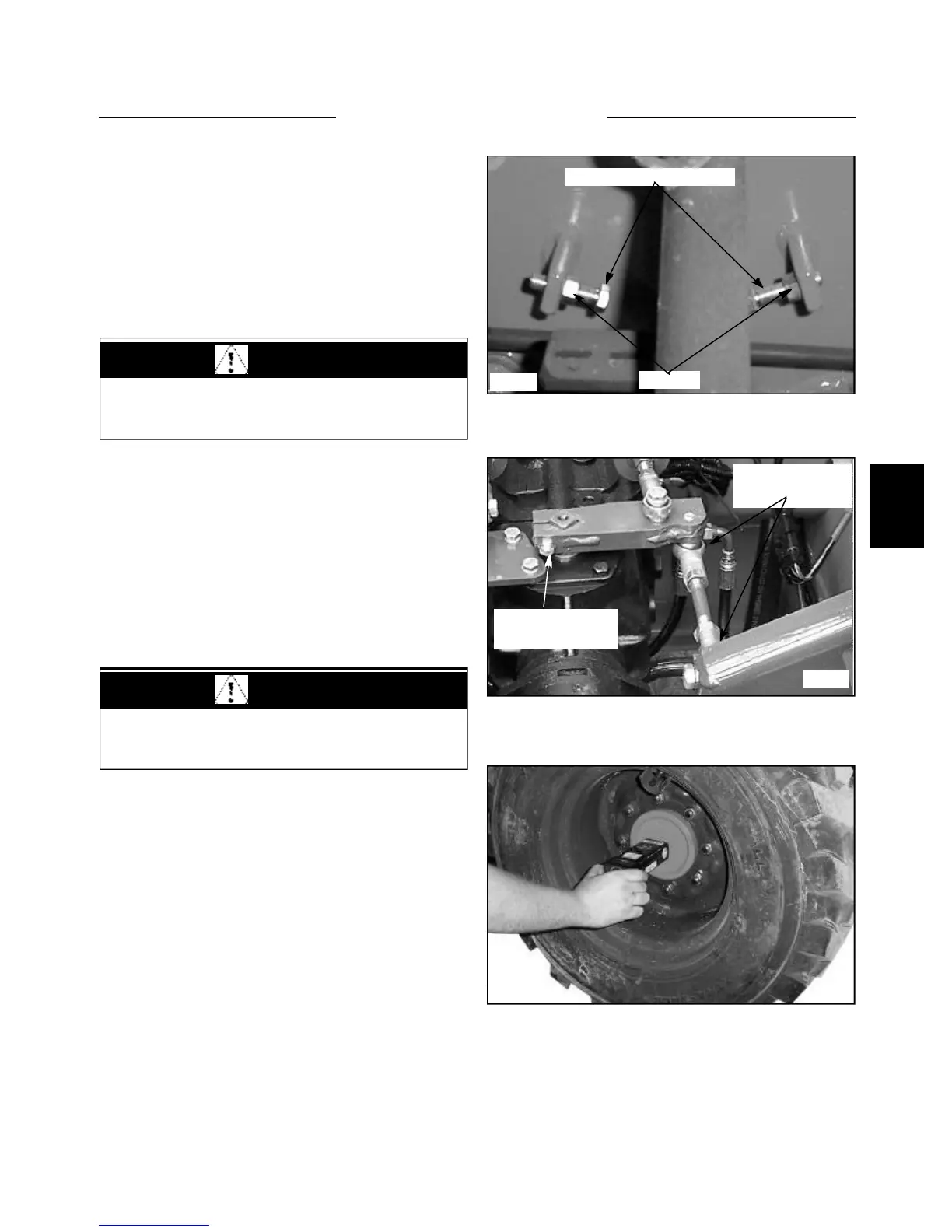

2 Remove the seat and hydrostatic shield. Note the

location of the steering control limiter bolts located front

and rear of each steering control lever, just below the

pivot point.. (fig. C3559)

3 Make sure the neutral adjustments are adjusted cor-

rectly. Refer to pages 4- 4 ~ 4-6.

4 If and when all rod bushings and pivot points have

been check for wear or binding, proceed with the wheel

speed adjustment.

5 Start the engine and release the parking brake. Adjust

the engine RPM to the full high idle position. Refer to

Section 7 to verify engine RPM.

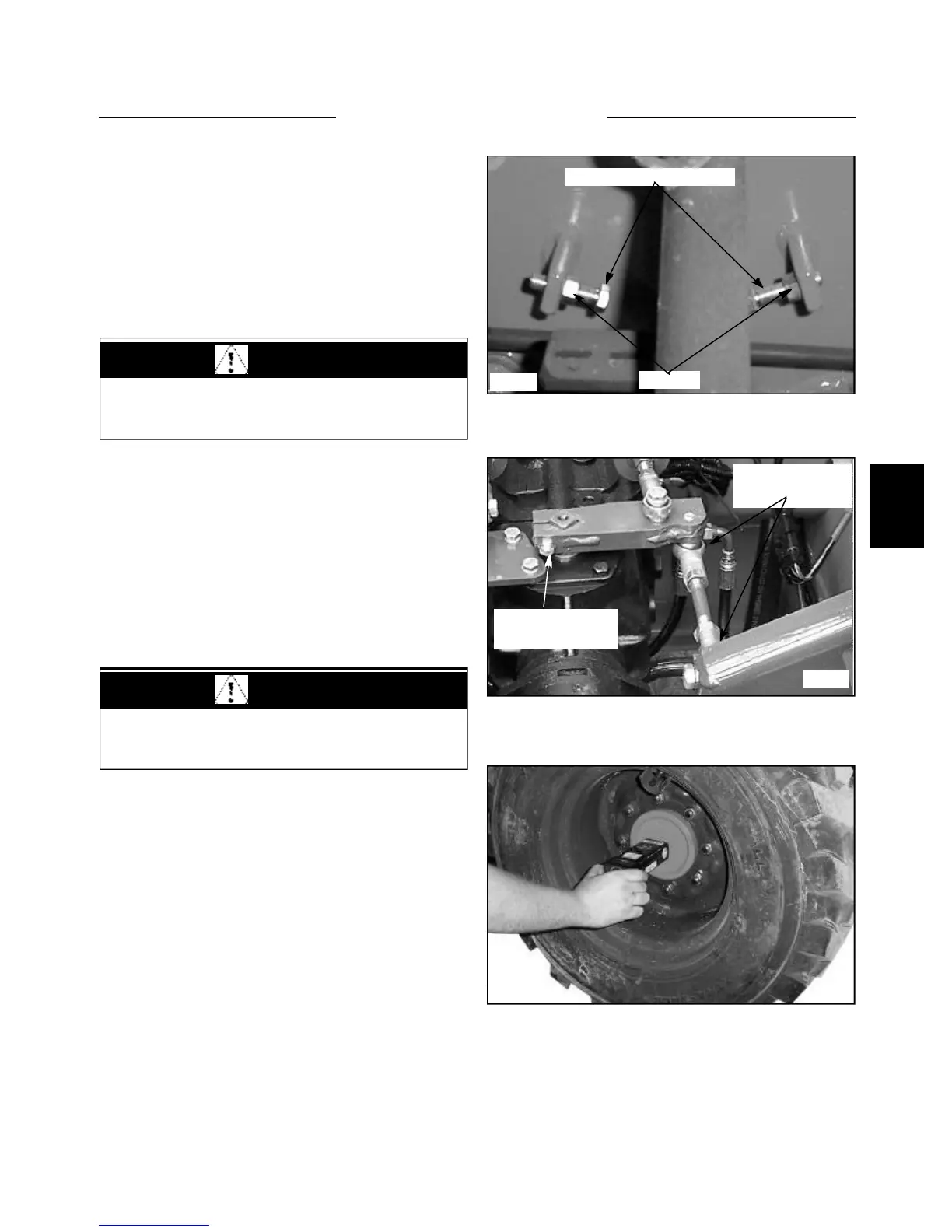

6 Using an RPM surface speed measuring tool

(Thomas P/N 43981) check each wheel speed in the for-

ward and reverse direction. Repeat for opposite side. (fig.

C3560)

7 Correct wheel speed is set evenly at 83 RPM forward

and reverse for both sides.

8 If adjustment is necessary, loosen the jam nut (fig.

C3559) and turn the limiter bolt in to increase wheel

speed or out to slow it down.

9 Tighten the jam nut and retest the speed adjustment.

Repeat if necessary.

10 Replace the seat and hydrostatic shield.

Note: If the wheel speed does not meet the above specifi-

cation, check the engine RPM. Refer to Section 7.

If the engine RPM checks out good you may need to

check for hydrostatic problems such as drive motor seal

leakage etc. Refer to Section 2 for testing procedures.

C3559

Speed control limiter bolts

Jam nuts

Check rod end

bushings for wear

Check pintle lever

tightness

C3560

STEERING 4.1

C3554

WARNING

Never work under the boom arms without the boom

supports engaged.

WARNING

Raise the loader securely off the ground before start-

ing the engine.

Loading...

Loading...