2-4

GENERAL INFORMATION 2.2

The driveshaft of the piston pump is rotated by the engine. The

piston block which is splined to the driveshaft also turns. The

piston block, rotating group, consists of 9 piston assemblies

which have free swiveling shoes swagged on the ball end of

each piston assembly. The shoe end of the piston rides against

the smooth machined surface of the swashplate. With the swash-

plate in the neutral position, the piston assemblies do not recip-

rocate in the piston block, but are rotating. No oil is drawn into

or discharged from the pump. The pump is in a zero displace-

ment position and the loader remains stationary.

With the swashplate in the neutral position, the pressure of the

charge oil, which ranges from 200 psi (13.8 Bar), is able to

unseat both check valves and supply oil to both sides of the

pump because of the balance in pressure. Very little charge oil

volume is required in the neutral position so the excess oil is

bypassed over the charge pressure relief valve and recirculated

back to the reservoir. The oil that leaks internally in the pump

and motor collects in their body housings and is returned to the

reservoir by external case drain in the pump and motors. This

leakage oil is the only oil the charge check replenishes. This

makes the design a closed loop system.

As the steering lever is moved forward, or reverse, the loader

starts a directional movement. As the swashplate begins to

move, the piston assemblies start to reciprocate in the piston

block. As the steering lever continues further movement the cam

angle increases, the pistons reciprocate further, more oil is

pumped and the speed of the loader is increased.

The drive motor, which is a fixed displacement type, delivers a

constant output torque for a given pressure throughout the speed

range of the motor.

The movement of the pump swashplate, forward or reverse,

controls the direction of the drive motor rotation.

The function of the pressure relief valve is to relieve the pres-

sure side of the system of excessive high pressure when the

loader encounters a heavy load or stalls out.

When the relief valve senses an over load it unseats, allowing

excess pressure and volume to flow into the low pressure side of

the pump. A small volume of oil starts to flow across to the

other relief valve. This relief valve is exposed to the low pres-

sure on the intake side of the pump and is seated by the spring

tension within the relief valve body.

The small volume of oil being bypassed is enough to unseat the

relief valve and let it recirculate back into the inlet side of the

pump. As the pressure continues to build on the pressure side, a

larger volume of oil flows and at a greater speed through the

drilled orifice in the relief valve cartridge, causing a pressure

drop inside the relief valve. The surrounding pressure is now

able to unseat the relief valve and bypass maximum volume of

oil. The system reliefs function the same for both sides of the

system.

When the swashplate begins to move the check valve on the dis-

charge, or pressure, side seats because of the higher pressure

differential. The other check valve remains open on the intake

or low pressure side to continue supplying the closed loop sys-

tem with charge oil.

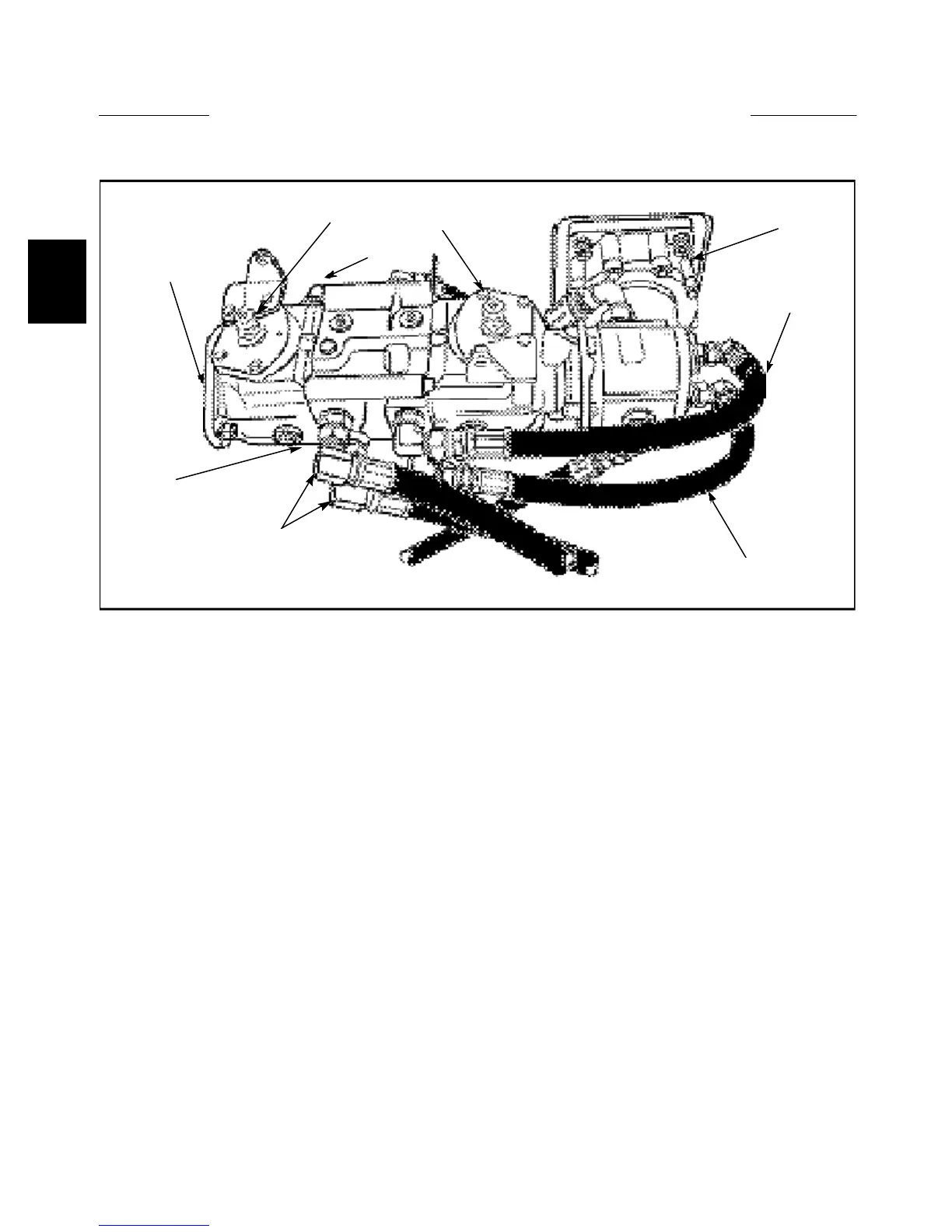

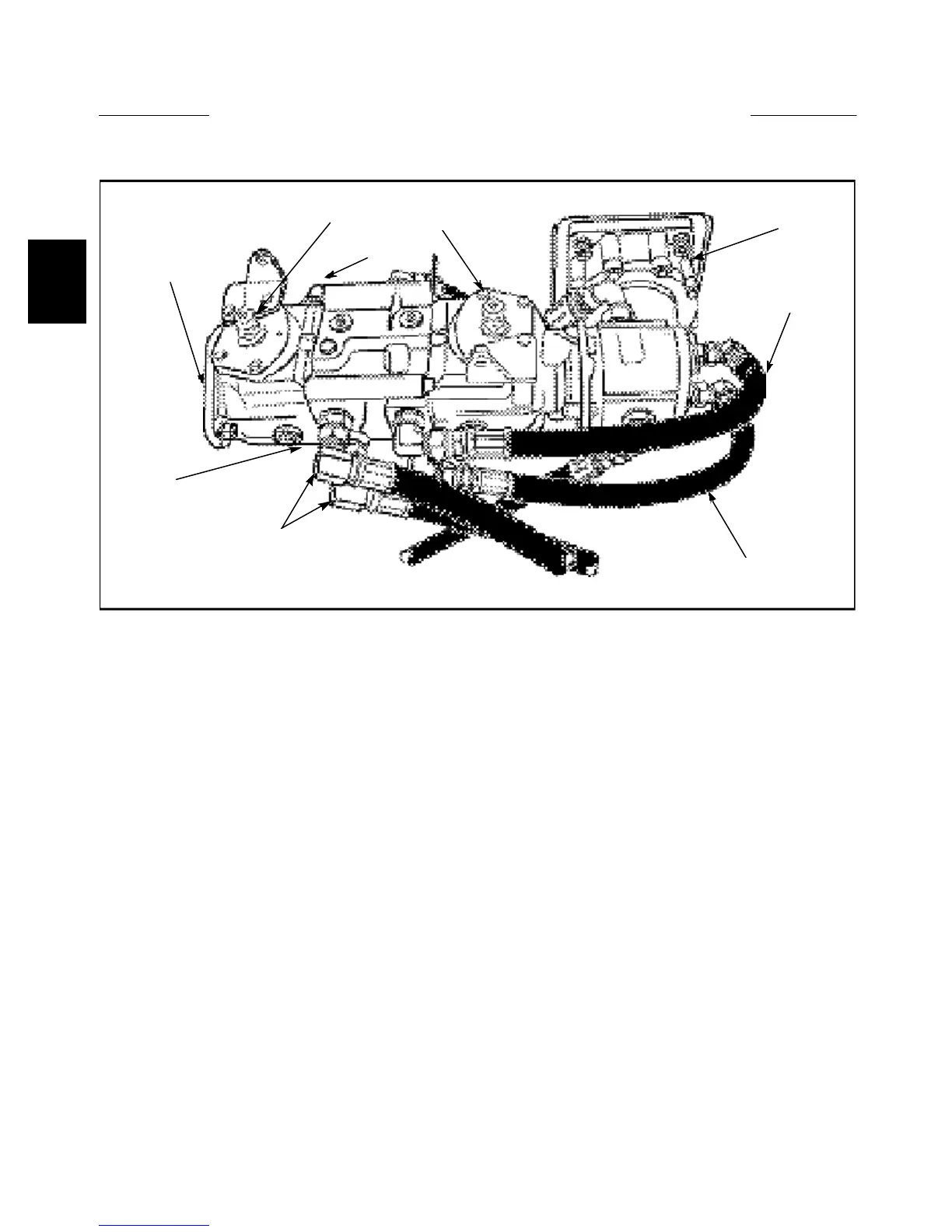

C3760

Clockwise input

shaft rotation

Counterclockwise

swash plate rotation

High pressure

High pressure

Case drain

High pressure

Fixed displacement

drive motor

Variable displacement

piston pump

Introduction:

Charge pressure inlet

Loading...

Loading...