Boom Arm Supports

For safety while performing regular service or mainte-

nance work, the loader is equipped with boom supports.

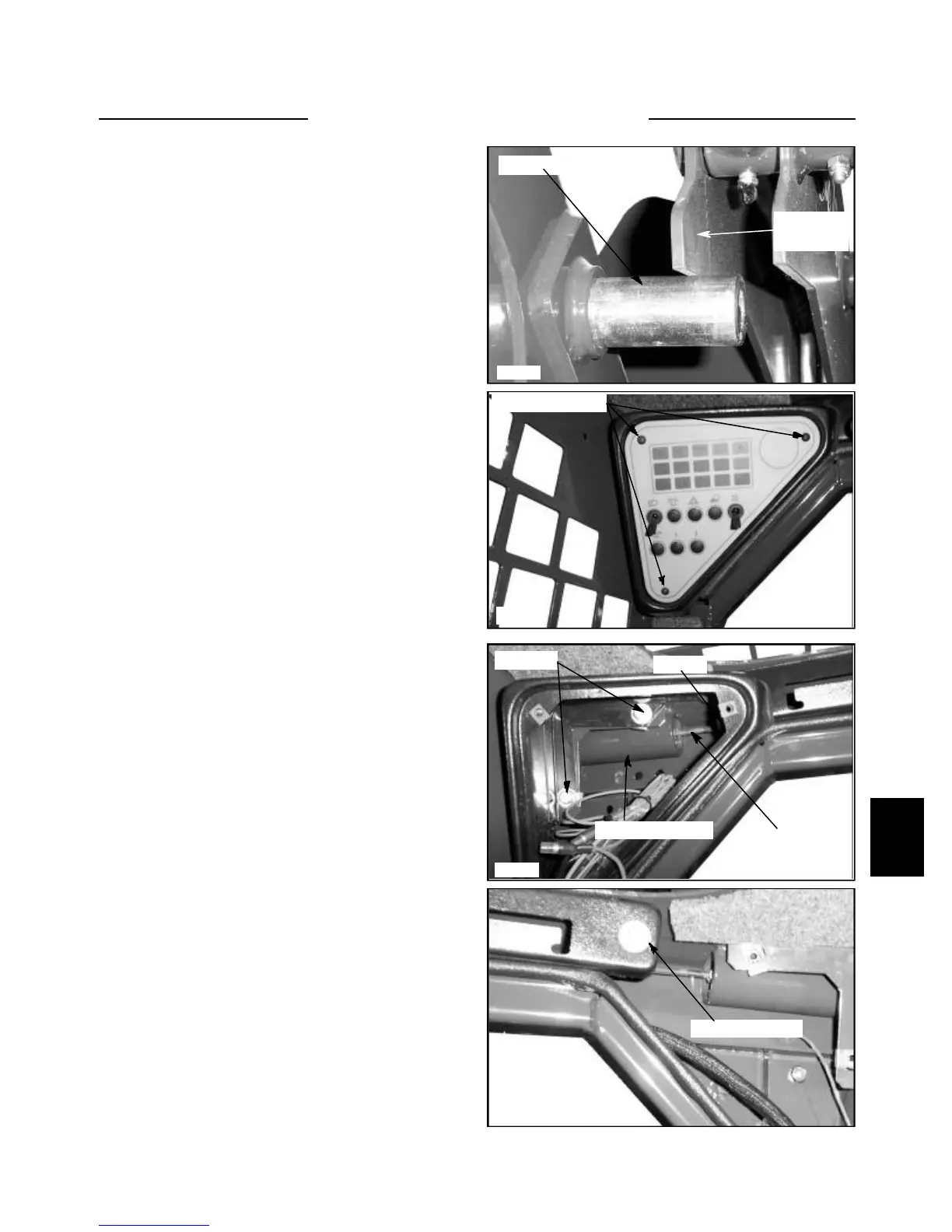

(fig. C3597) The boom supports, when extended, prevent

the boom arm from lowering when servicing the

hydraulic system, controls or other repair work while the

engine is not operating.

The boom supports should be greased every 8 hours of

use and engagement depth should be checked every time

the supports are used.

1 Raise the boom arms, extend the boom supports and

allow the boom arms to lower onto the supports. Do not

pressure the hydraulic system against the boom supports.

2 Shut off the engine and engage the parking brake.

3 Measure the distance the boom support pins are pro-

truding past the inner boom arm plate. Proper adjustment

should have the support pin protruding past the inner

boom arm plate by 1/4 of an inch. (6.5mm) (fig. C3597)

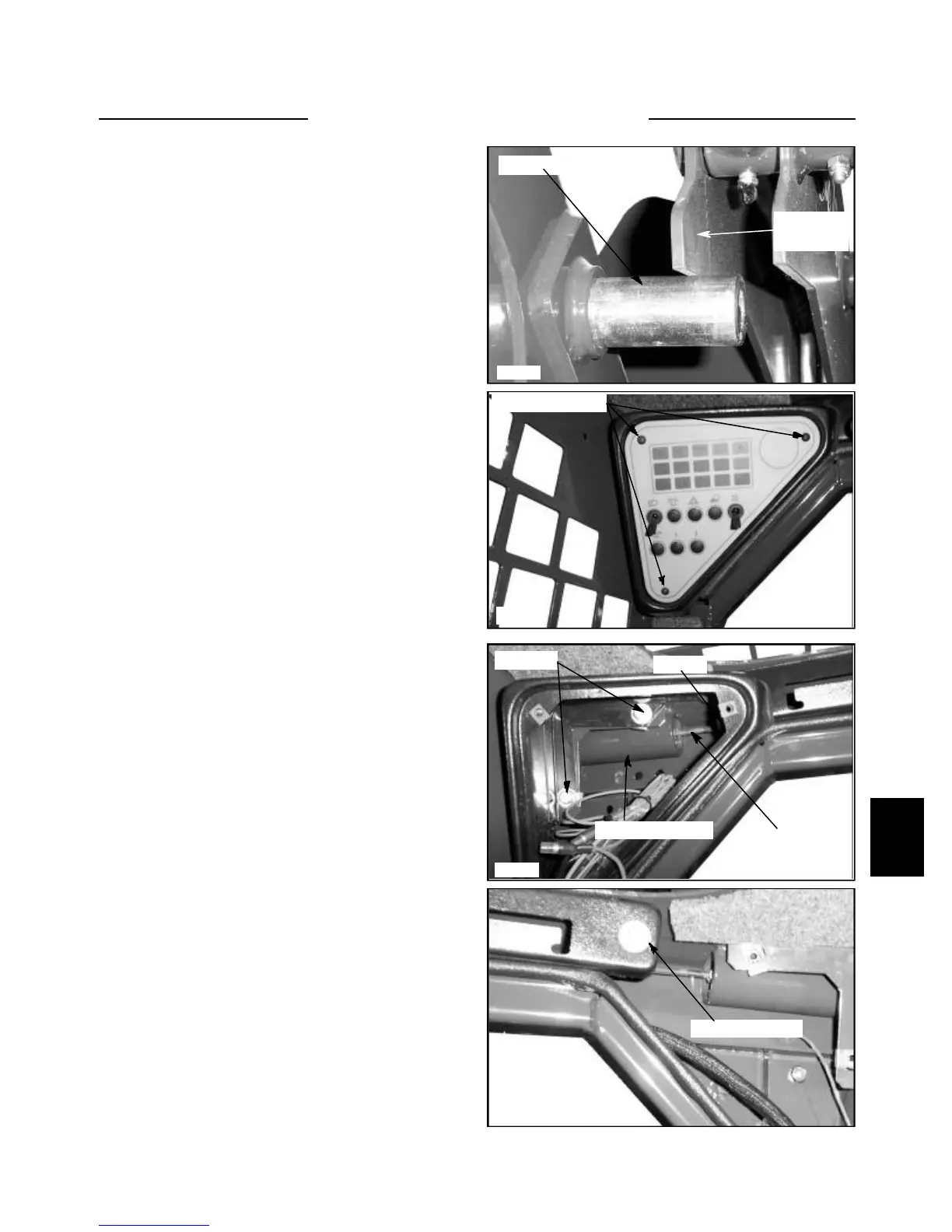

4 Adjust the engagement depth by removing the 3

screws each on the left and right dash panels to access the

support pins and linkage. (fig. C3577) Only remove one

side if there is only one side to be adjusted.

5 Loosen the jam nut on the support pin linkage. (fig.

C3579) Use care to not damage the plastic center dash

panel.

6 Screw the pin in or out the amount necessary to get

the proper adjustment for support pin engagement on the

boom arms.

7 To remove the support pins and linkage, remove both

dash panels and pods to access the center boom support

panel bolts. (fig. C3598)

8 Remove the bolts and center panel and the support

pins and linkage may be removed, serviced or repaired.

9 Apply 242 Loctite (blue) to the nut and tighten it

against the support pin when installing.

10 Lubricate the boom support pins and replace the dash

panels.

6-7

C3597

C3598

C3579

C3577

Boom support pin

Boom arm

plate

Mounting screws

Pod bolts

Boom support pin

Jam nut

Linkage

Center panel bolt

BOOM ARMS 6.2

Loading...

Loading...