TOWING 2.5

Towing Procedure

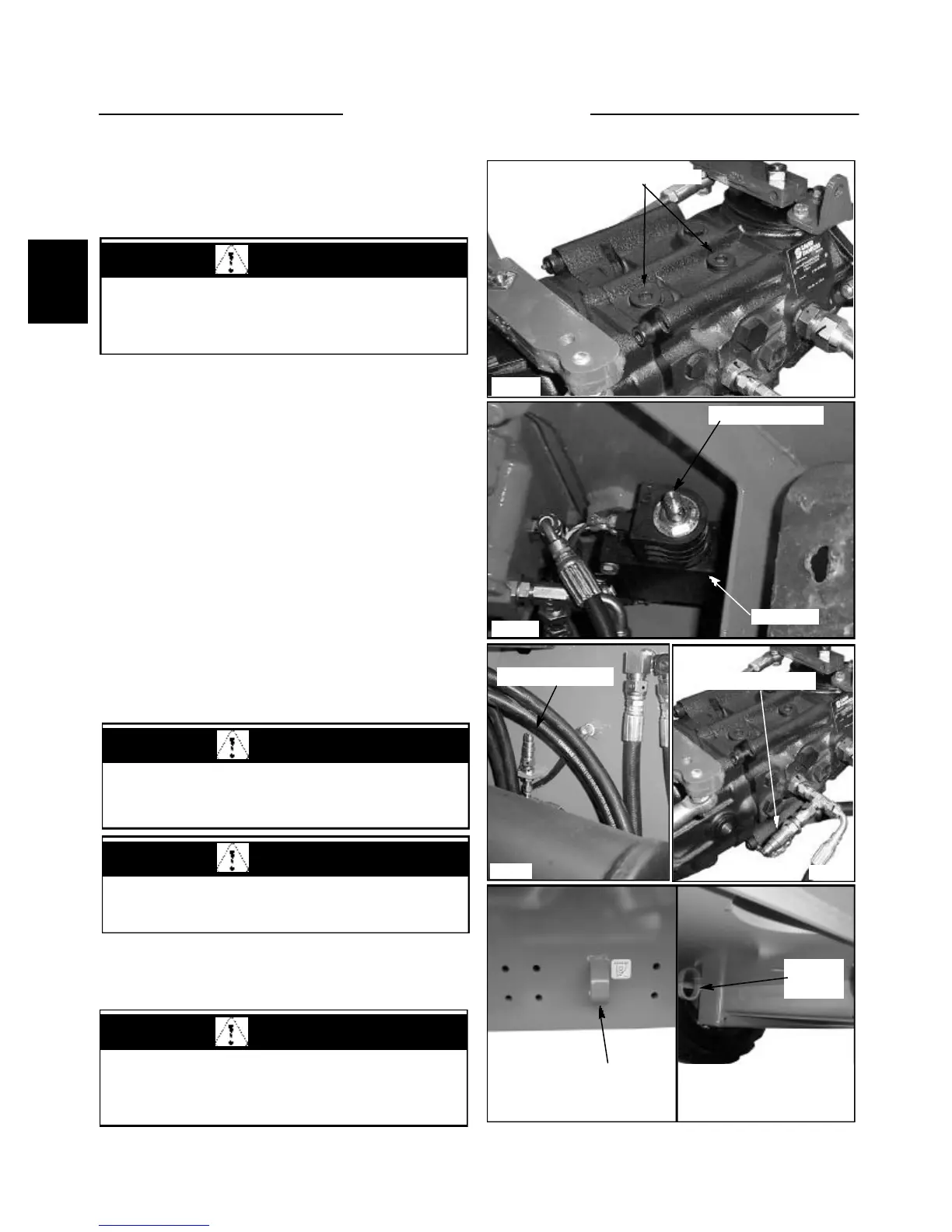

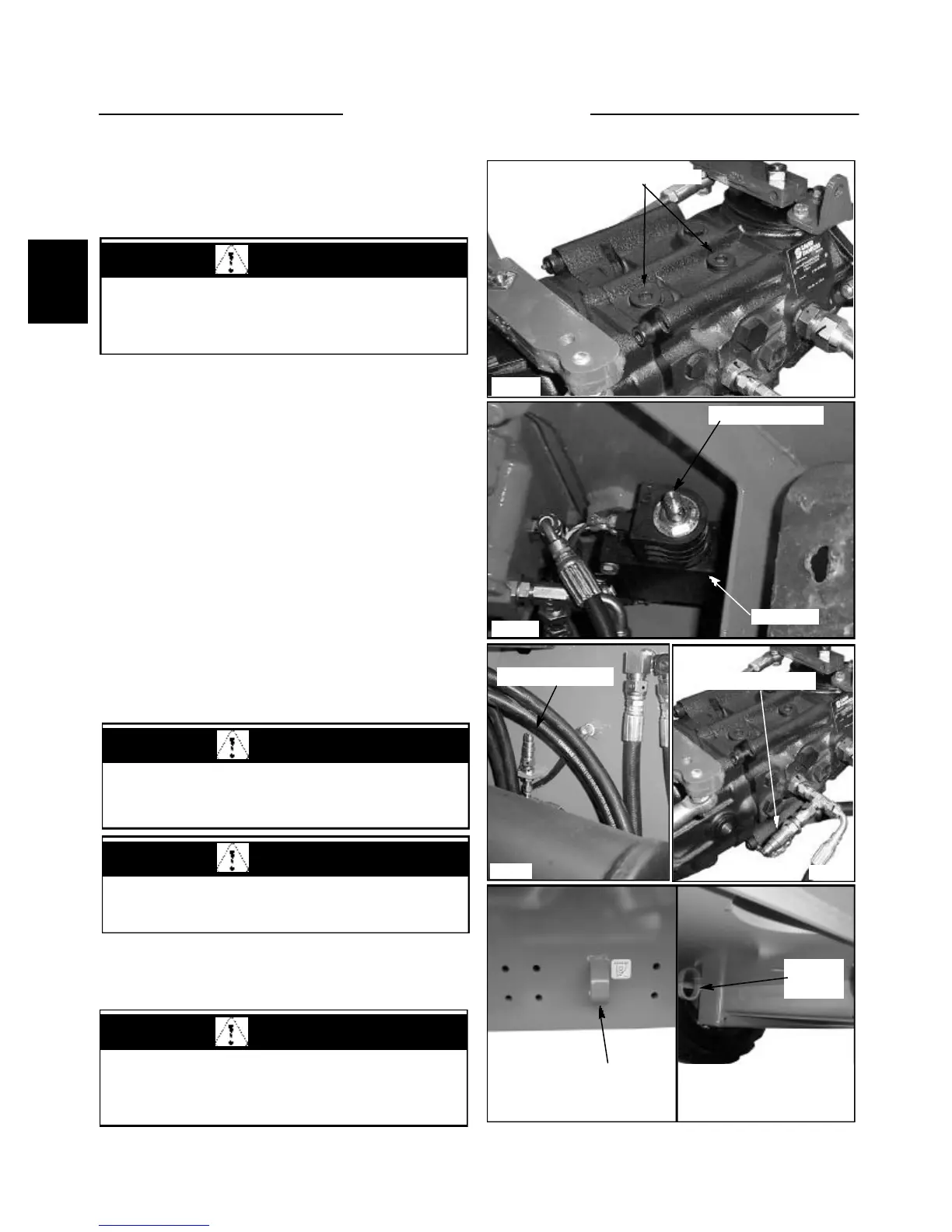

In the event the loader has malfunctioned or failed, the

loader may be moved a short distance by following the

procedure below.

C3665

C3870

C3666

C3447

4 Use the front frame mounted tie downs to attach

pulling devise. ( fig. C3447 ) Use the rear tie downs to

pull the loader backwards. ( fig. C3446 )

1 Remove the seat and hydrostatic shield.

2 Loosen the high pressure relief valve caps 4 complete

turns. There are 4 high pressure relief valves, 2 on the top

side, and 2 on the bottom side of the tandem pump. Be

sure to loosen all 4. ( fig. C3665 ) Torque caps 30 to 50 ft

/ lbs (41 to 68 N.m.) upon reassembly.

3 The loader parking brake system is released by

hydrostatic pressure. To release the parking brake when

the unit has failed you must pressurize the brake system

manually. A service override for the brake valve has been

incorporated for use by Thomas Dealers. The normal

position of the plunger is down and turned into the locked

position. To release the brake, turn the release plunger

counter clockwise. (fig. C3666) Access of the small quick

connector for the 175 in the engine compartment.

(fiq.C3870) Access the small quick connector for the

1700 in the tandem compartment (fiq. C3871) Use a port

-a - power to pressurize this line to 200 psi (13.8 bar).

The brakes are now released.

C3446

Front tie down

Rear tie

down

Relief valve location

Brake release coupler

Brake release plunger

Brake valve

2-10

WARNING

Failure to follow the proper towing procedure may

cause damage to the hydrostatic drive system.

WARNING

Be sure to return the brake valve plunger to the

normal position after servicing the loader.

CAUTION

To prevent damage to the drive motors, do not

exceed speed of 1 MPH.

WARNING

Use chains or cables rated a minimum of 1 and 1/2

times the gross vehicle weight.

C3871

Brake release coupler

Loading...

Loading...