DriveSystem

Maintenance

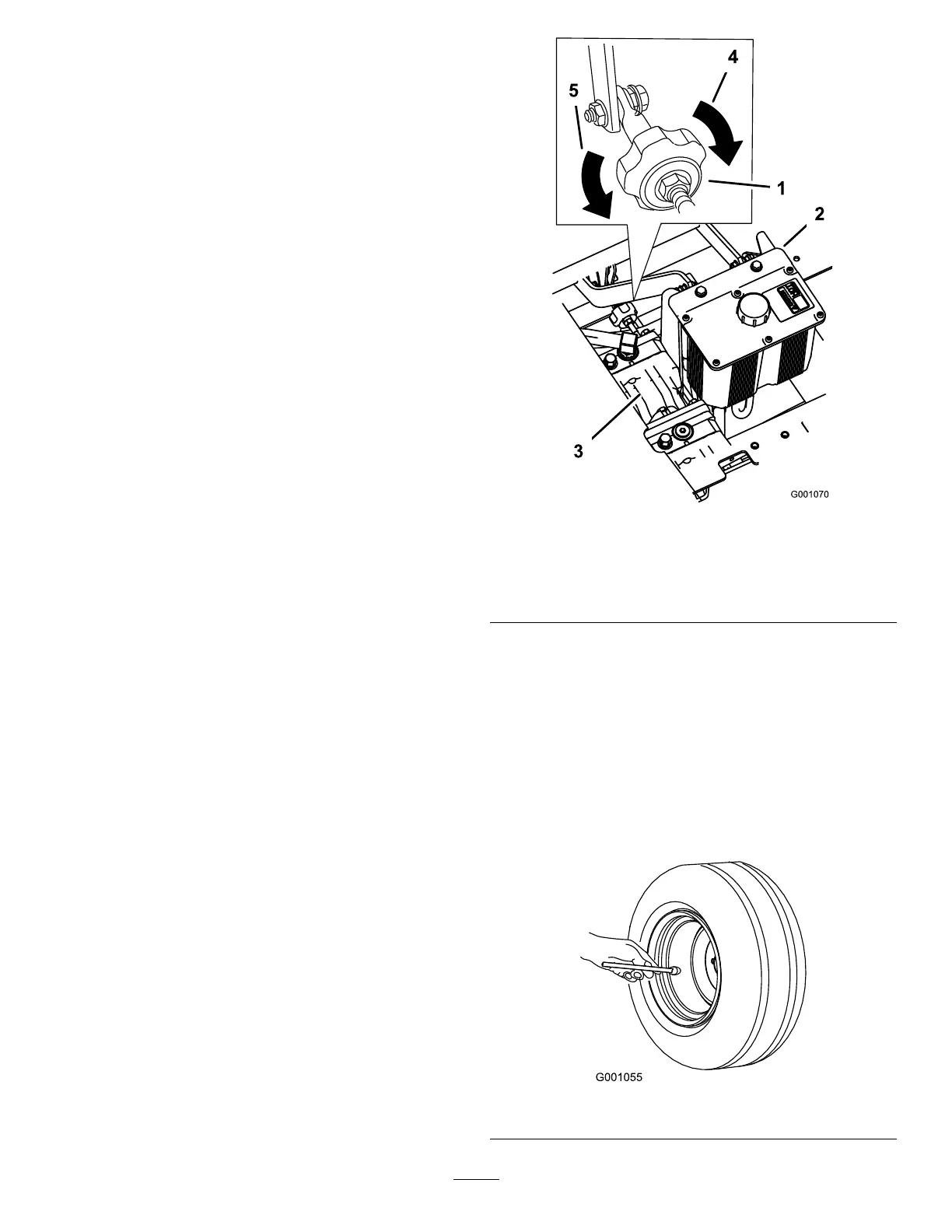

AdjustingtheTracking

Themachinehasaknobforadjustingthetrackinglocated

undertheseat.

Important:Adjustthehandleneutralandhydraulic

pumpneutralbeforeadjustingthetracking;referto

AdjustingtheControlHandleNeutralPosition(page

59)andSettingtheHydraulicPumpNeutralPosition

(page63).

1.Pushbothcontrolleversforwardthesamedistance.

2.Checkifthemachinepullsto1side.Ifitdoes,shutoff

themachineandengagetheparkingbrake.

3.Unlatchtheseatandtilttheseatforwardtoaccessthe

trackingknob.

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

4.Tomakethemachinegoright,turntheknobtoward

therightofthemachine;refertoFigure71.

5.Tomakethemachinegoleft,turntheknobtowardthe

leftofthemachine;refertoFigure71.

6.Repeatadjustmentuntilthetrackingiscorrect.

g001070

Figure71

1.Trackingknob4.Turnthiswaytotrackright.

2.Hydraulictank

5.Turnthiswaytotrackleft.

3.Hydraulicpumps

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Maintaintheairpressureinthereartiresat90kPa(13psi).

Uneventirepressurecancauseunevencut.Checkthetires

whentheyarecoldtogetthemostaccuratepressurereading.

Note:Thefronttiresaresemi-pneumatictiresanddonot

requireairpressuremaintenance.

g001055

Figure72

50

Loading...

Loading...