9.Applyslightrearwardpressureonthemotion-control

lever,turntheheadoftheadjustmentboltinthe

appropriatedirectionuntilthecontrolleveriscentered

intheNEUTRAL-LOCKposition(Figure90).

Note:Keepingrearwardpressureontheleverkeeps

thepinattheendoftheslotandallowtheadjustment

bolttomovethelevertotheappropriateposition.

10.Tightenthenutandjamnut(Figure90).

11.Repeatfortheoppositesideofthemachine.

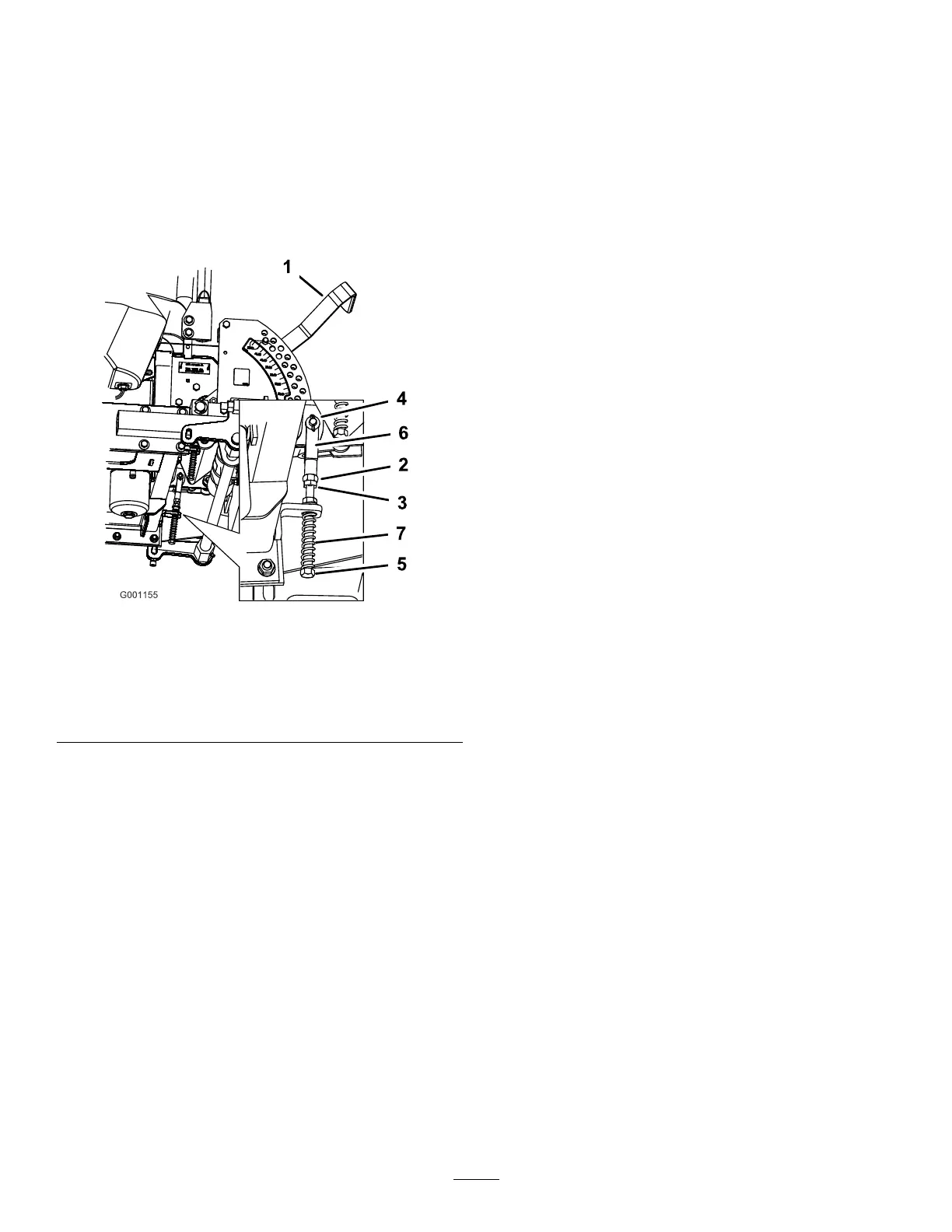

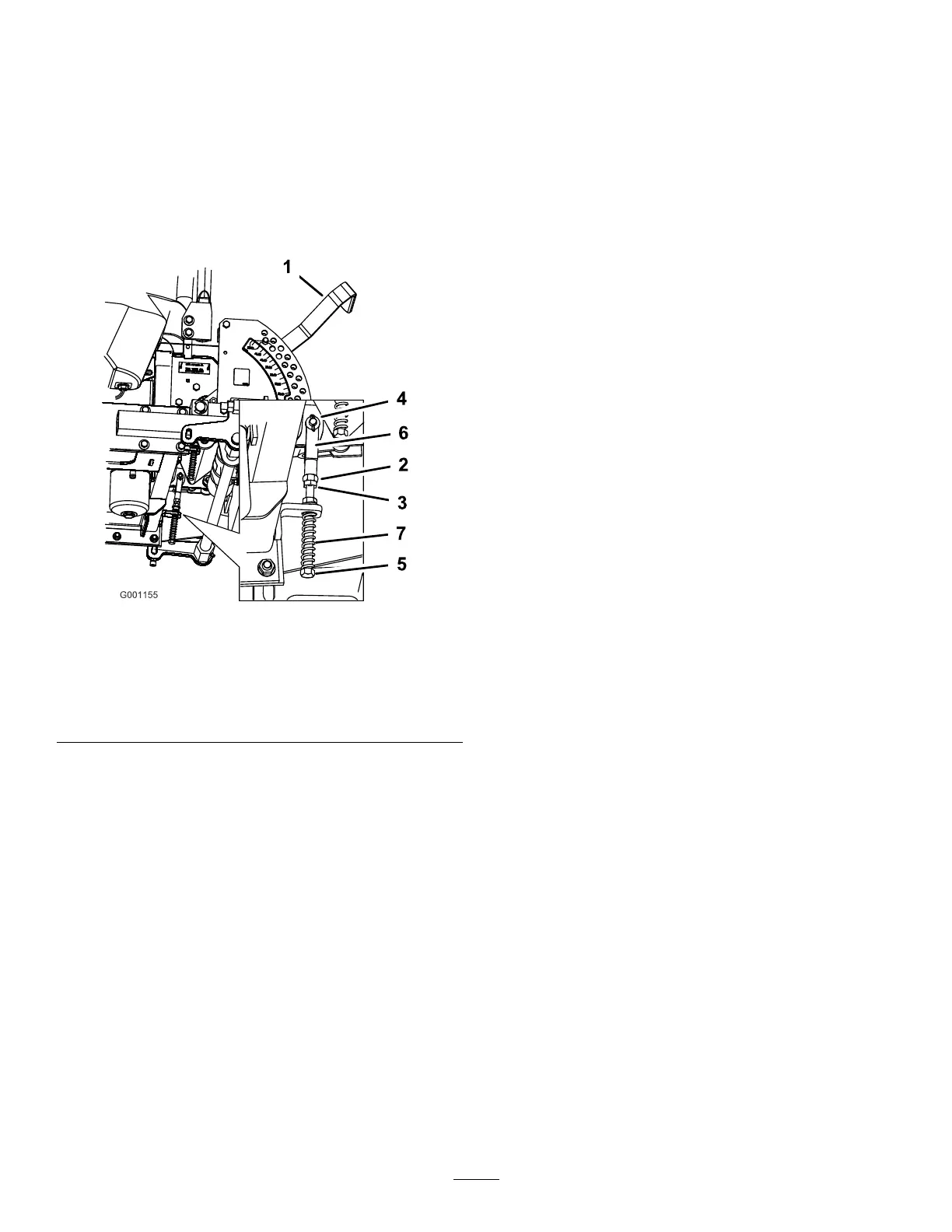

g001155

Figure90

1.Height-of-cutlever

5.Adjustmentbolt

2.Nutagainstyoke6.Yoke

3.Jamnut

7.Spring

4.Clevispininslot

HydraulicSystem

Maintenance

HydraulicSystemSafety

•Ensurethatallhydraulic-uidhosesandlinesarein

goodconditionandallhydraulicconnectionsand

ttingsaretightbeforeapplyingpressuretothe

hydraulicsystem.

•Keepyourbodyandhandsawayfrompinholeleaks

ornozzlesthatejecthigh-pressurehydraulicuid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulicsystem.

•Seekimmediatemedicalattentionifuidisinjected

intoskin.Injecteduidmustbesurgicallyremoved

withinafewhoursbyadoctor.

ServicingtheHydraulic

System

Hydraulic-FluidType:Toro

®

HYPR-OIL

™

500hydraulic

uidorMobil

®

115W-50uid

HydraulicSystemFluidCapacity:3.9L(132oz)

Important:Usethespecieduid.Otheruidscould

causesystemdamage.

CheckingtheHydraulic-FluidLevel

ServiceInterval:Aftertherst8hours

Every25hours

Note:Thereare2waysofcheckingthehydraulicuid.One

iswhentheuidiswarmandoneiswhentheuidiscold.

Thebafeinsidethetankhas2levelsdependingiftheuid

iswarmorcold.

1.Positionthemachineonalevelsurfaceandengagethe

parkingbrake.

2.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

andengagetheparkingbrake.

3.Shutofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Cleantheareaaroundthellerneckofthehydraulic

tank(Figure91).

5.Removethecapfromthellerneckandlookinsideto

checkifthereisuidinthereservoir(Figure91).

6.Ifthereisnouid,adduidtothereservoiruntilit

reachesthecoldlevelofthebafe.

60

Loading...

Loading...