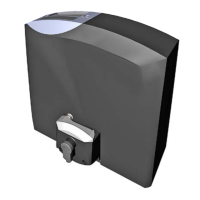

Why is my tousek Gate Opener not reacting when giving an impulse?

- MMr. Daniel VillanuevaAug 17, 2025

If your Tousek gate opener isn't reacting to an impulse, it could be due to a couple of reasons. First, check the line voltage and safety fuses, as there might be no line voltage or a broken safety fuse. Secondly, there might be an issue with the transmitter, control device, or impulse button, such as the transmitter not being programmed. In this case, check the transmitter/control device, program the transmitter, and verify the battery.