136 RTHD-SVX01D-EN

Maintenance Procedures

Parts Ordering Information

Use the Table 30, “Connection Devices,” on page 136 for part ordering infor-

mation.

Obtain the required parts from your local Trane Parts Center.

Chemical Cleaning Procedure

• Scale deposits are best removed by chemical means. Consult a qualified

water treatment specialist (i.e., one that knows the local water supply

chemical/mineral content) for a recommended cleaning solution suitable

for the job. (A standard condenser water circuit is composed solely of

copper, cast iron and steel.) Improper chemical cleaning can damage

tube walls.

Evaporator

F

1

3 107 (235) M12x1.75 NA NA

Evaporator

F

1

2 107 (235) M12x1.75 NA NA

Evaporator

D/E

1

3 91 (201) M12x1.75 NA NA

Evaporator

D/E

1

2 110 (243) M12x1.75 NA NA

Evaporator

B/C

1

3 76 (167) M12x1.75 NA NA

Evaporator

B/C

1

2 91 (201) M12x1.75 NA NA

Evaporator

B/C

1

2 73 (160) M12x1.75 NA NA

Condenser

G

2

2 102 (226) M12x1.75 297 (655)

Lifting Lug

3

Condenser

E/F

2

2 66 (146) M12x1.75 239 (526)

Lifting Lug

3

Condenser

B/D

2

2 53 (116) M12x1.75 187 (412)

Lifting Lug

3

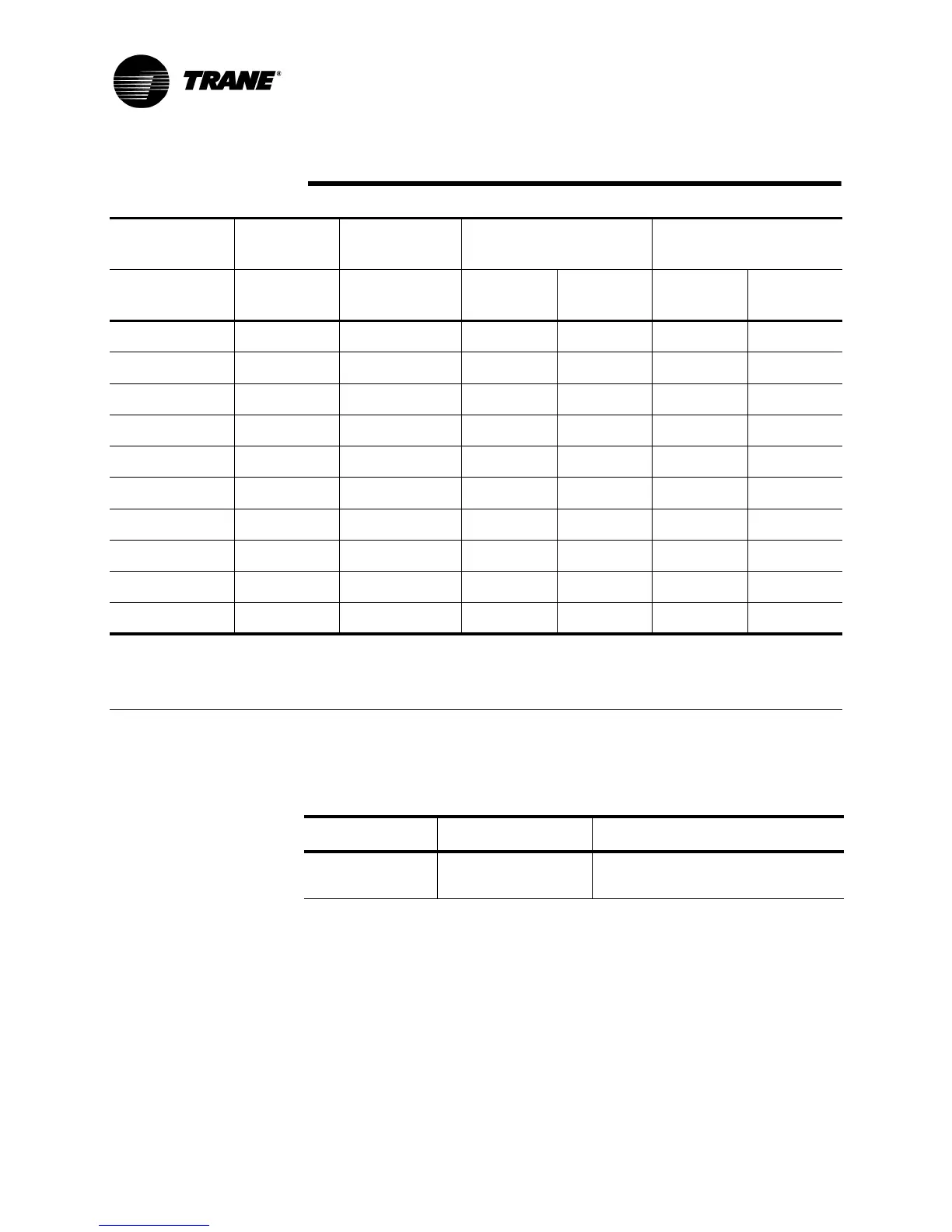

Table 29 RTHD Waterbox Weights

Standard Grooved Pipe

Waterbox

Marine Style Waterbox

Waterbox Size

Number of

Water Passes

Weight

Kg (lbs)

Lifting

Connection

Weight

Kg (lbs)

Lifting

Connection

1

Digit 14 of the model number

2

Digit 21 of the model number

3

Removable cover has a weight of 136 Kg (300 lbs) Lifting Connection M12x1.75 tapped hole

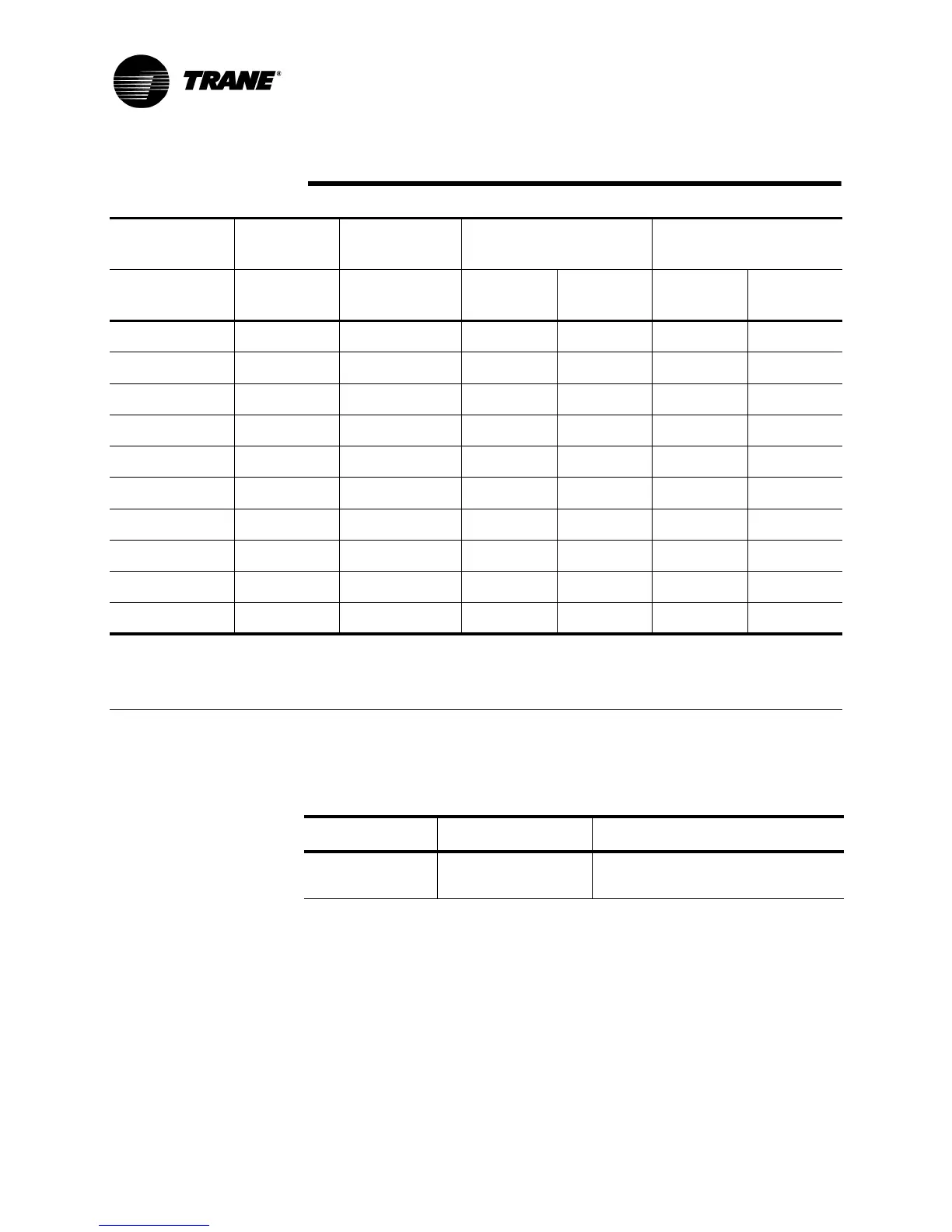

Table 30 Connection Devices

Unit Product Part Number

RTHD Safety Hoist Ring

M12x1.75

RNG01886

Loading...

Loading...