RTHD-SVX01D-EN 77

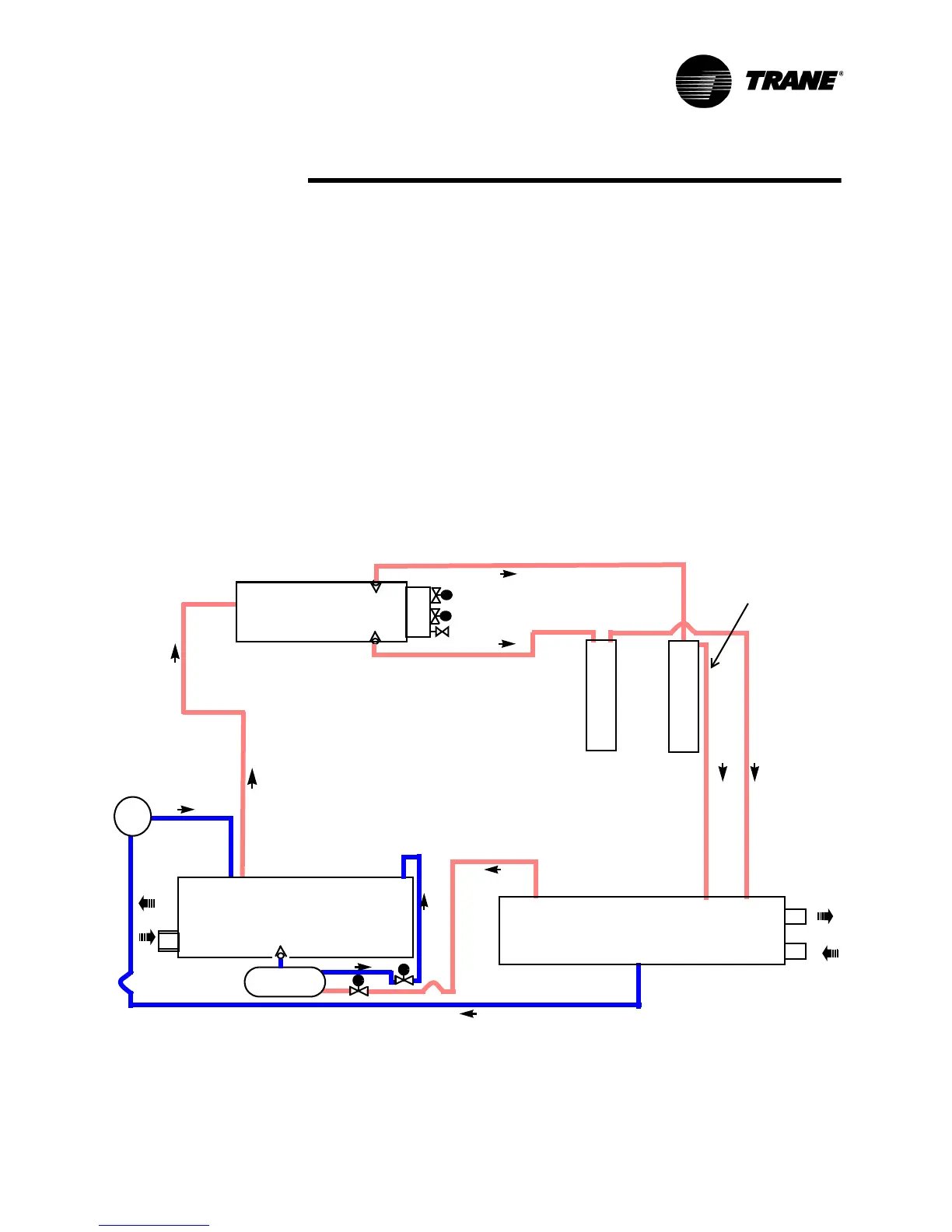

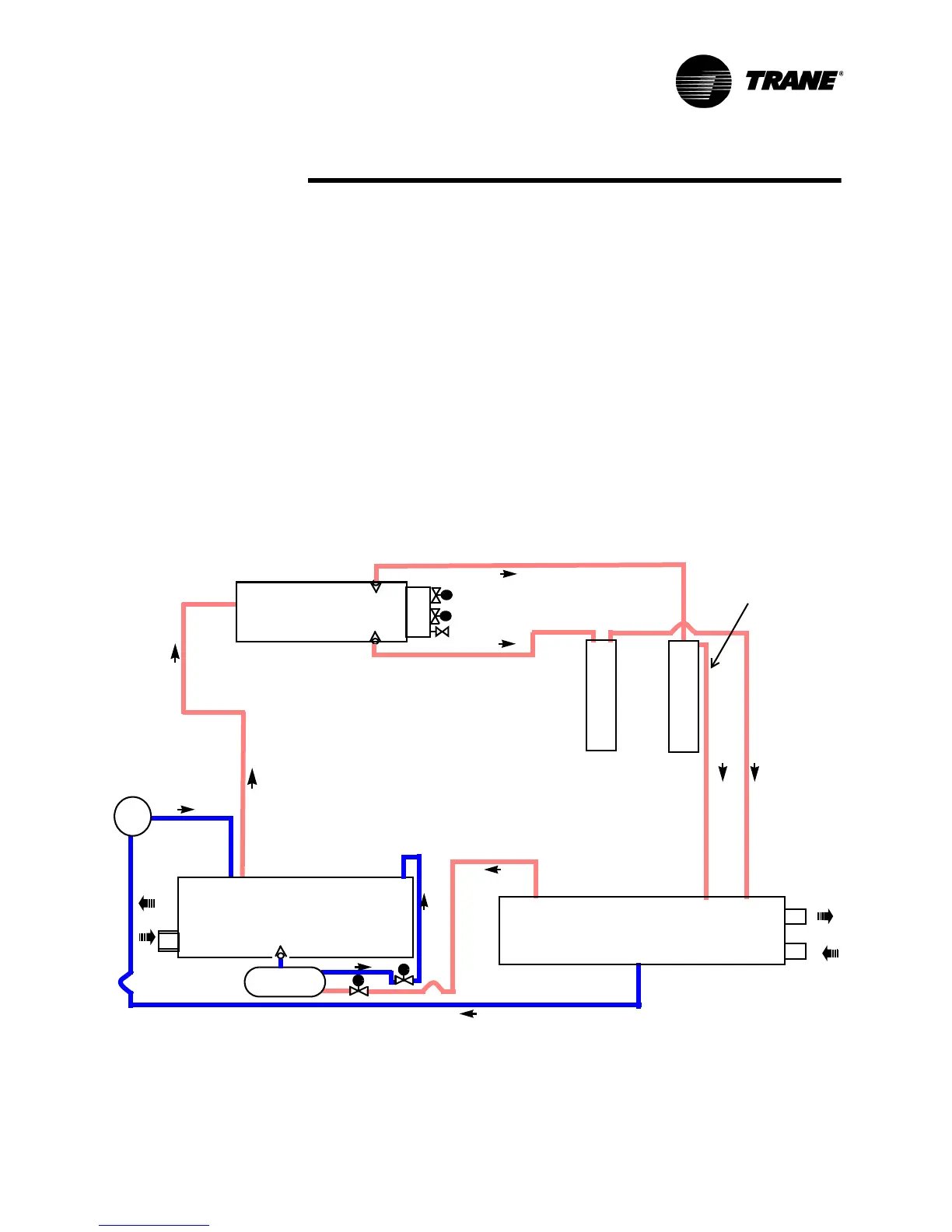

Operating Principles Mechanical

As the refrigerant leaves the bottom of the condenser (State Pt. 3), it enters

an integral subcooler where it is subcooled before traveling to the electronic

expansion valve (State Pt. 4). The pressure drop created by the expansion

process vaporizes a portion of the liquid refrigerant. The resulting mixture of

liquid and gaseous refrigerant then enters the Evaporator Distribution system

(State Pt. 5). The flash gas from the expansion process is internally routed to

compressor suction, and while the liquid refrigerant is distributed over the

tube bundle in the evaporator.

The RTHD chiller maximizes the evaporator heat transfer performance while

minimizing refrigerant charge requirements. This is accomplished by meter-

ing the liquid refrigerant flow to the evaporator’s distribution system using the

electronic expansion valve. A relatively low liquid level is maintained in the

evaporator shell, which contains a bit of surplus refrigerant liquid and accumu-

lated lubricant. A liquid level measurement device monitors this level and pro-

vides feedback information to the CH530 unit controller, which commands

the electronic expansion valve to reposition when necessary. If the level

rises, the expansion valve is closed slightly, and if the level is dropping, the

valve is opened slightly such that a steady level is maintained.

Figure 23 Refrigerant Flow Diagram

condenser

s

e

p

a

r

t

o

a

e

p

a

r

t

o

a

s

evaporator

compressor

gas pump

EXV

dual discharge lines only on C, D & E frame compressors

dual discharge lines

only on C, D & E frame

compressors

r

r

Loading...

Loading...