RTHD-SVX01D-EN 81

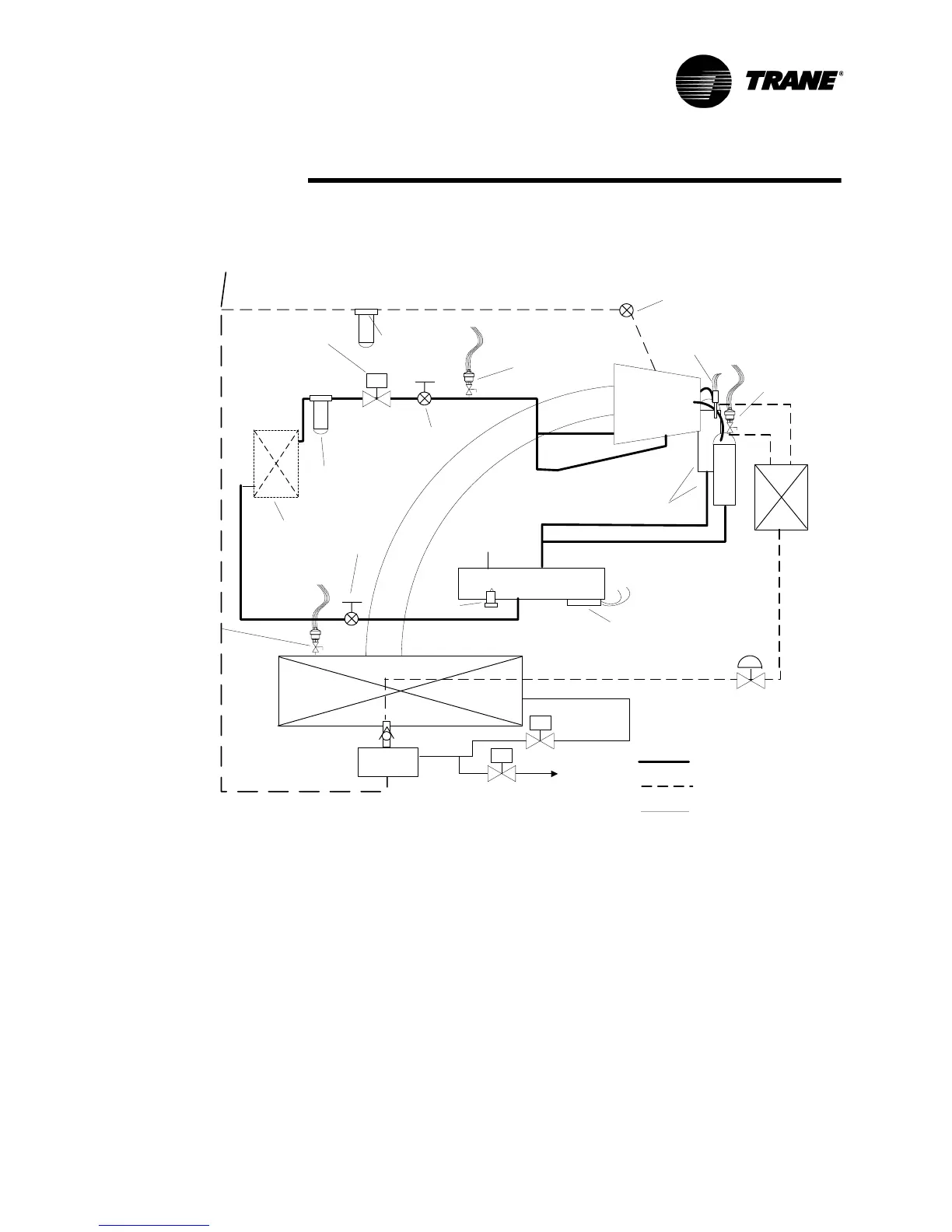

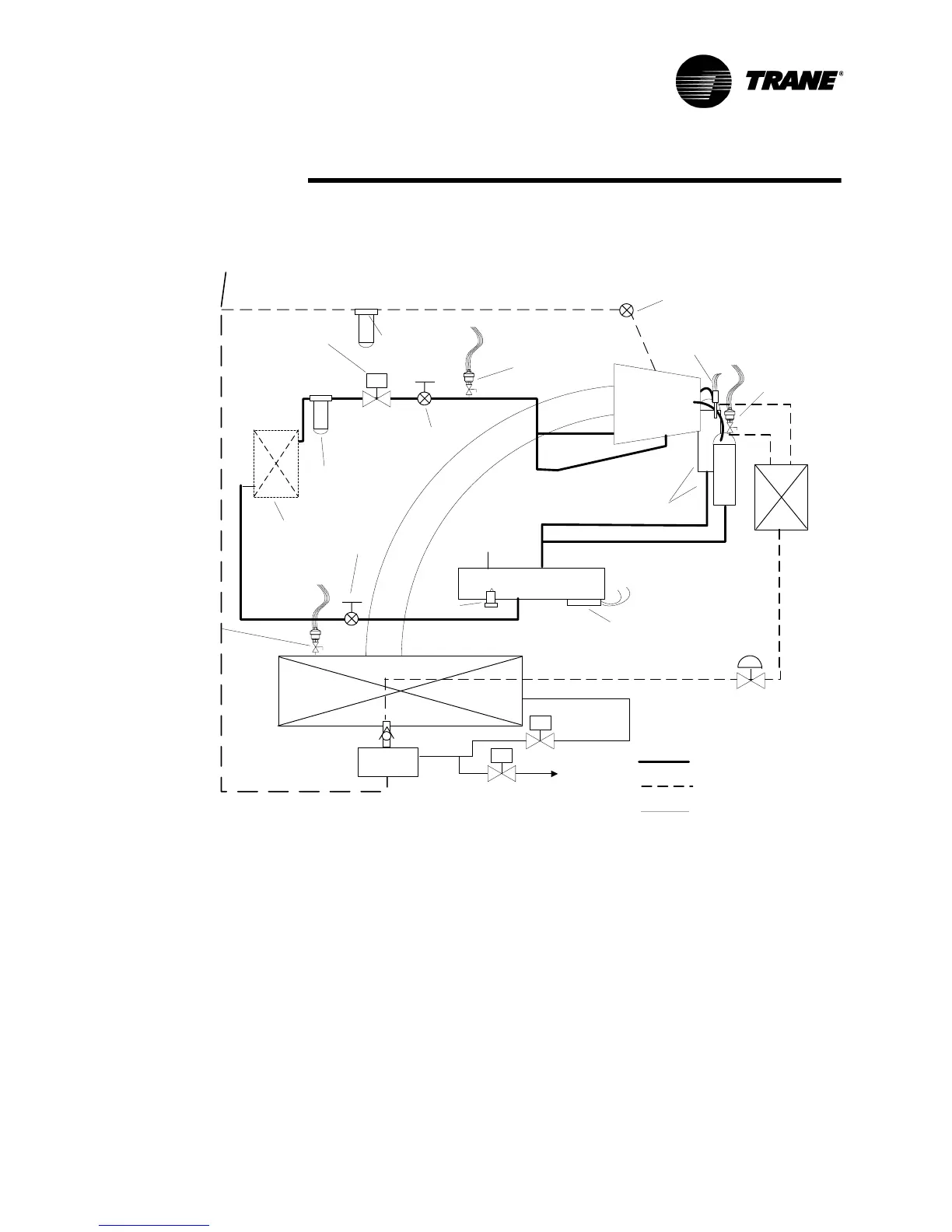

Operating Principles Mechanical

Oil that collects in the oil tank sump is at condensing pressure during com-

pressor operation; therefore, oil is constantly moving to lower pressure areas.

Oil Flow Protection

Oil flowing through the lubrication circuit flows from the oil sump to the com-

pressor (see Figure 25). As the oil leaves the sump, it passes through a ser-

vice valve, an oil cooler (if used), oil filter, master solenoid valve, and another

service valve. Oil flow then splits into two distinct paths, each performing a

separate function: (1) bearing lubrication and cooling, and (2) compressor oil

injection.

Oil flow and quality is proven through a combination of a number of sensors,

most notably a pressure transducer and the optical oil level sensor.

Figure 25 Oil Flow Diagram

Evaporator

Pressure

Transducer Pe

Evaporator

RTHD Oil System

Oil Filter

Optional Oil

Cooler

Oil Heaters

Master Oil Line

Solenoid

Oil Separators

Oil Sump

Vent to

Condenser

To Bearings

Injection to

Rotors

Oil Return

Gas Pump

Vent Line

To Condenser

Pressure

Oil/Refrigerant

Mixture

Oil Recovery

Fill Solenoid

Valve

Drain Solenoid

Valve

Liquid/Vapor

Refrigerant Mixture

Condenser

EXV

Primary Oil System

Refrigerant & Oil

Mixture-Oil Recovery

System

Manual

Service

Valve

Optical Oil

Detector

Oil Pressure

Transducer

Condenser

Pressure

Transducer

Other

Oil Return Filter

restrictor

Compressor

Compressor

Discharge

Temperature

Sensor

Manual

Service

Valve

Loading...

Loading...