36

PKG-SVX027D-EN

discharge line (and condenser liquid line) access port

valves.

If charge is present, continue with piping installation.

If no nitrogen escapes the access valve, leak test the unit

refrigerant system to determine the leak source, and repair.

See Maintenance section, “Refrigerant Leak Test

Procedure,” p. 66. After finding leak, remove test pressure

and repair leak using proper brazing procedures. See

Maintenance section, “Brazing Procedures,” p. 67. Retest

unit(s) to ensure all leaks are repaired. Continue with piping

installation.

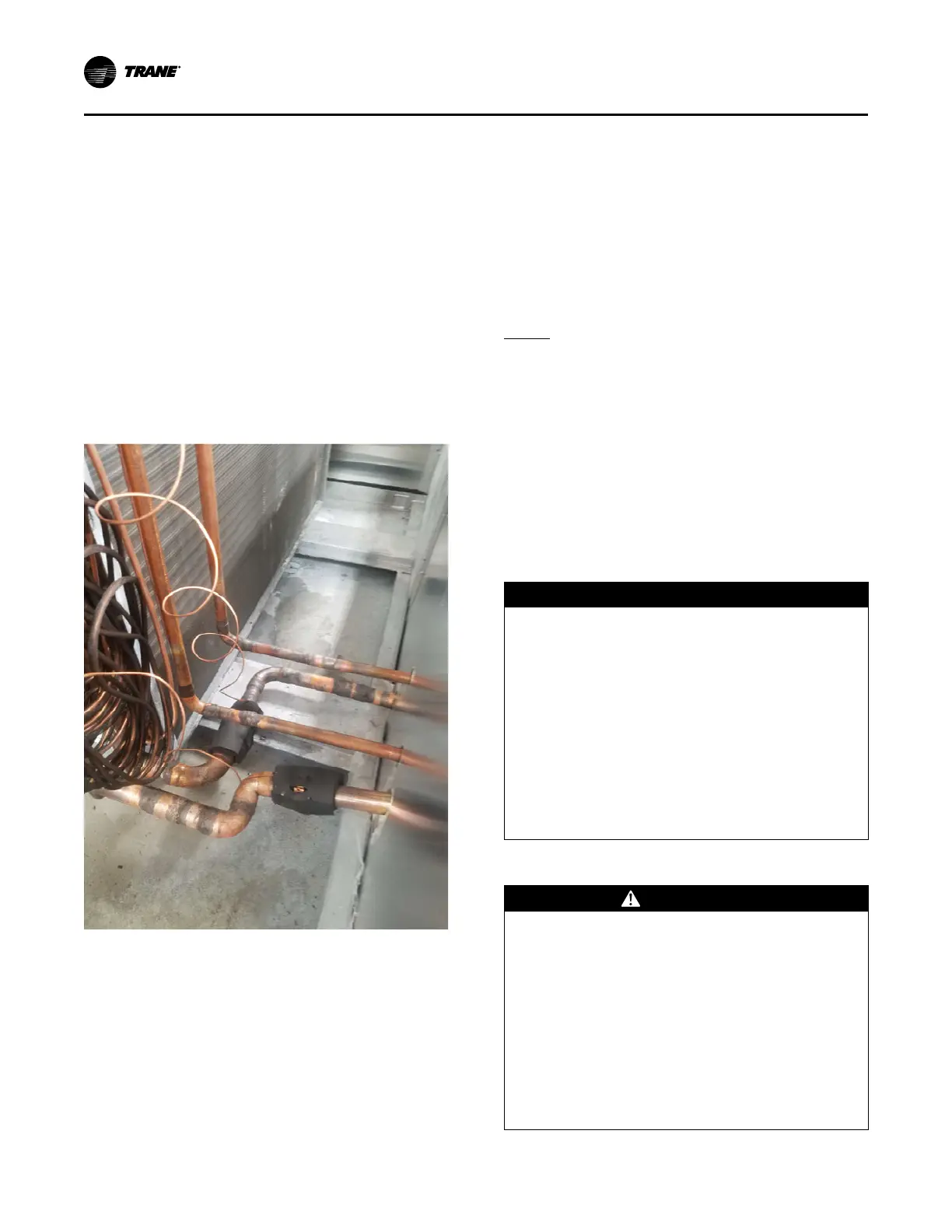

Braze suction and liquid lines between evaporator module

and condensing unit cassettes.

See Maintenance section, “Refrigerant Leak Test

Procedure,” p. 66 /“Brazing Procedures,” p. 67.

Figure 21. Braze suction and liquid lines

Interconnecting Piping

Refrigerant piping must be properly sized and applied.

These two factors have a significant effect on both system

performance and reliability.

Install interconnecting piping using proper installation and

brazing procedures.

Work on only one circuit at a time to minimize system

exposure to potentially harmful moisture in the air.

Before installing piping verify compressor oil levels are

near top of sight glass or above.

Note: MSC units (and replacement compressors) ship fully

charged with POE oil from the factory. Scroll

compressors use POE 32 oil, DO NOT substitute.

Capped discharge and liquid line connections are located

near bottom, left side of the condensing unit cassette.

Remove caps with a tube cutter to minimize risk of getting

chips inside piping.

Cleanliness is extremely important during system

installation to minimize residual contaminants, such as

oxidization and scale.

Tightly strap TXV bulbs to horizontal run of each suction

line and insulate. Attach vacuum pump and begin

evacuation as soon as piping installation is complete. This

starts system dehydration and helps prevent POE

compressor oil contamination. This will also indicate large

leaks if vacuum does not hold (below 400 microns and hold

for 2 hours). Complete Leak Test and Evacuation (for

procedures, see “Refrigerant Leak Test Procedure,” p. 66

and “System Evacuation Procedures,” p. 68 in

Maintenance section) before starting “Preliminary

Refrigerant Charging,” p. 36.

Note: Use Type “L” refrigerant grade copper tubing only.

Important: Failure to tighten bulb to suction line, can result

in erratic operation of unit.

NOTICE

Compressor Damage!

POE oil is hygroscopic – it absorbs water directly

from the air. This water is nearly impossible to remove

from the compressor oil and can result in compressor

failures.

To prevent POE oil from absorbing water, the system

should not remain open for longer than necessary.

When open, dry nitrogen should flow through the

piping. Only new oil containers should be used for

service and maintenance. Always use the smallest

container size required for the job requirements.

Always leave the oil container tightly sealed until time

of use. Do not reuse oil that has been opened.

Preliminary Refrigerant Charging

WARNING

Confined Space Hazards!

Failure to follow instructions below could result in

death or serious injury.

Do not work in confined spaces where refrigerant or

other hazardous, toxic, or flammable gas may be

leaking. Refrigerant or other gases could displace

available oxygen to breathe, causing possible

asphyxiation or other serious health risks. Some

gases may be flammable and/or explosive. If a leak in

such spaces is detected, evacuate the area

immediately and contact the proper rescue or

response authority.

Installation - Mechanical

Loading...

Loading...