PKG-SVX027D-EN

53

from the factory as an option or it can be field-provided.

Whenever the flow switch detects a water flow loss prior to

or during mechanical cooling, compressor operation locks

out and a diagnostic code displays. If water flow is

restored, the compressor operation automatically restores.

Waterside Economizer Option

The waterside economizer option takes advantage of

cooling tower water to either pre-cool the entering air to aid

the mechanical cooling process or, if the water temperature

is low enough, provide total system cooling.

The waterside economizer includes a coil, modulating

valves, controls, and piping. The coil construction is ½-inch

(13 mm) OD seamless copper tubes expanded into

aluminum fins. The evaporator and economizer coils share

a common sloped (IAQ) drain pan. Drain pan options are

either galvanized or stainless steel, and insulated.

The tubes are arranged in a staggered pattern to maximize

heat transfer. The coil has round copper supply and return

headers with removable clean-out and vent plugs.

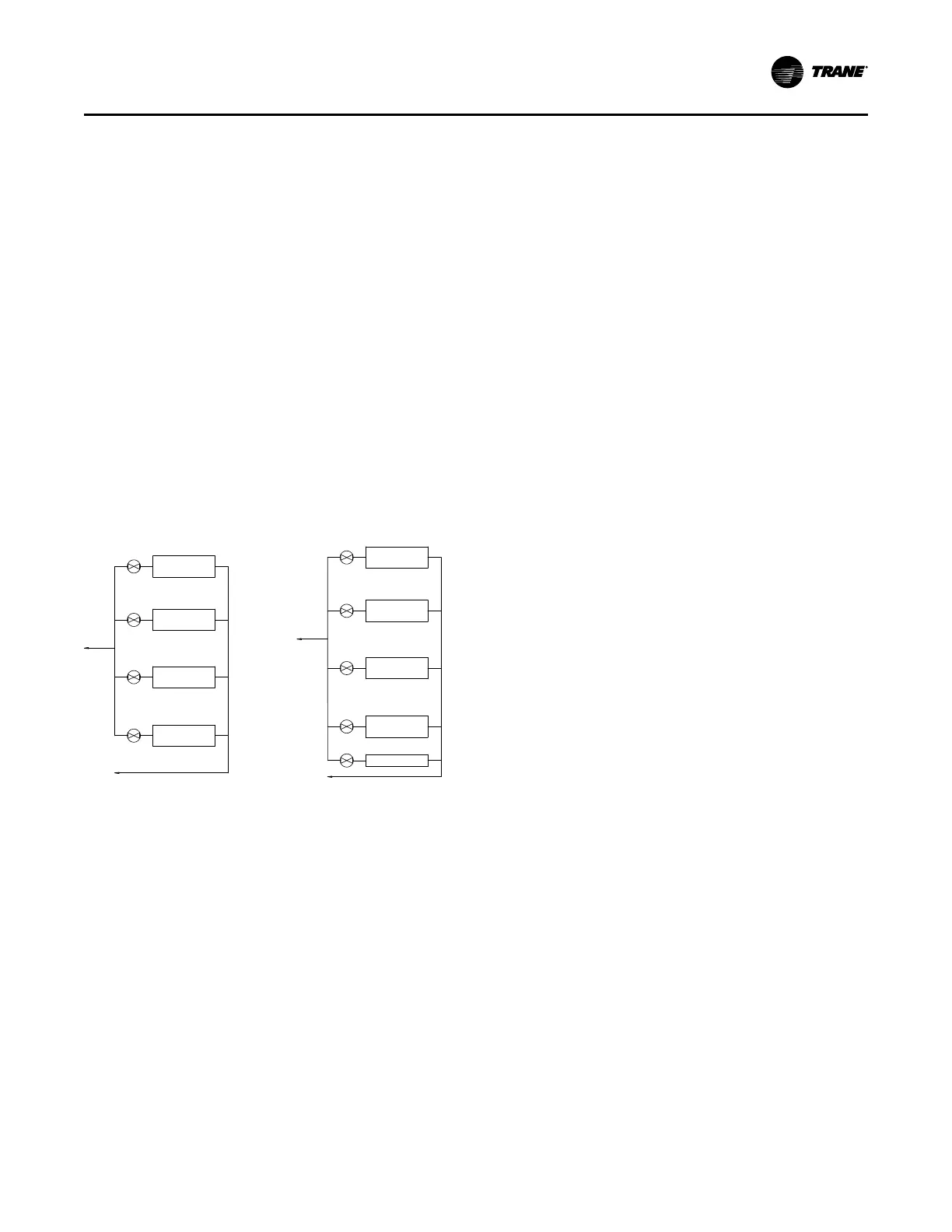

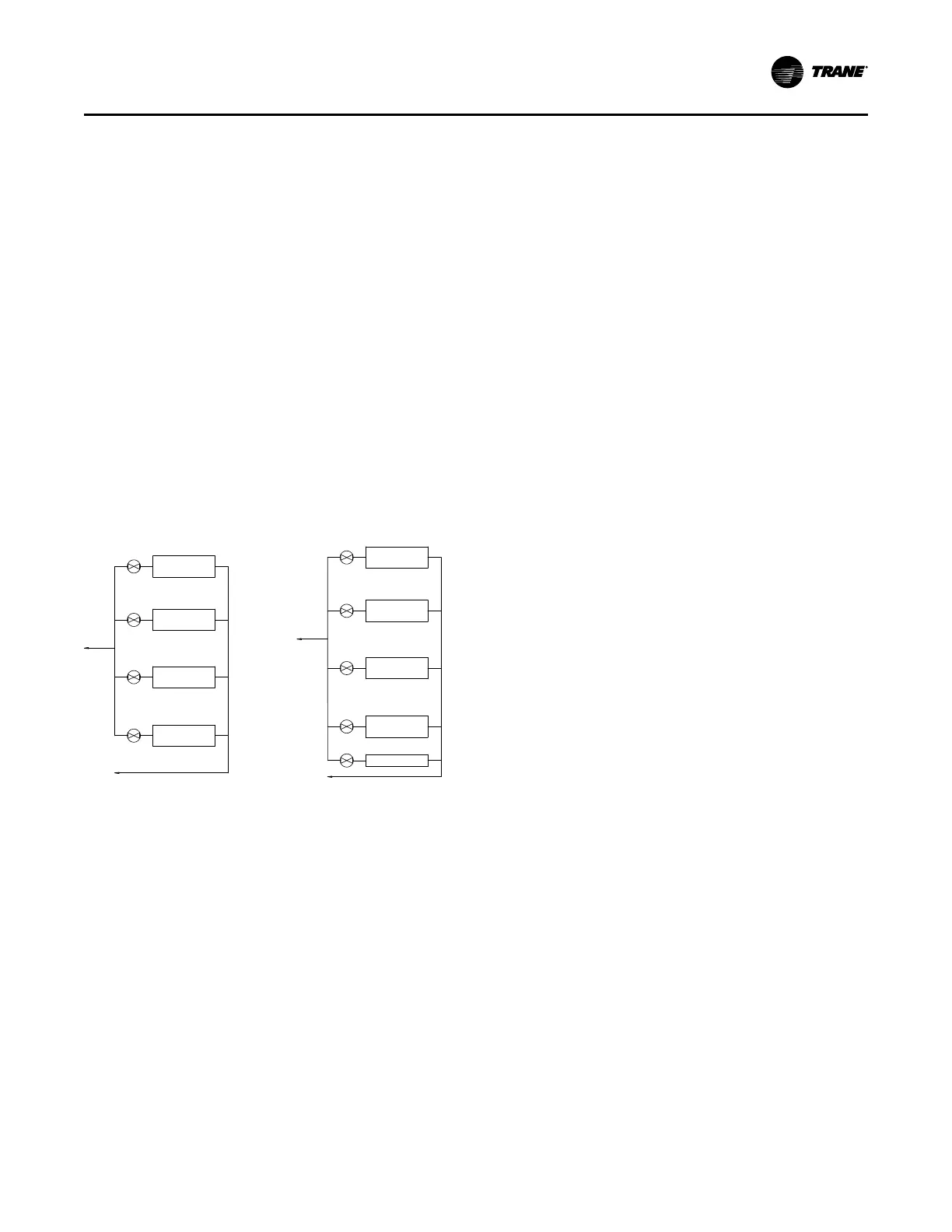

Figure 42. Basic water piping, constant water flow

Condenser 2

Condenser 3

Condenser 4

Condenser 3

Condenser 4

Condenser 2

WSE

Condenser 1

Condenser 1

Basic water piping, constant water flow Basic water piping, constant water flow

with WSE

Heat Mode

The BAS Heat option consists of a fin and tube hot-water

coil, an electrically actuated ball valve, and control

software.

When the MSC Operating Mode is set to BAS HEAT, the

UC600 controller ends any Cooling Mode operation

(Mechanical and/or Water Side Economizer) and

transitions to control Discharge Air Temperature to the BAS

HEAT setpoint temperature. The UC600 does this by

opening and closing the Heating ball valve. The Fan Array

is controlled normally to maintain static pressure to the

Static Pressure Setpoint.

If the Discharge Air Temperature exceeds 104°F a

Manually Resettable High Discharge Air Temperature

Diagnostic is annunciated.

High Duct Temperature Thermostat

An optional factory-supplied temperature limit switch with

reset element detects the supply air duct temperature. This

sensor should be field-installed downstream from the

discharge in the supply air duct. If the supply air duct

temperature exceeds 240°F (115.6°C), the unit shuts down

and displays a diagnostic. A manual reset is required at the

unit. High duct temperature can be adjusted at thermostat.

Dirty Air Filter Sensor Option

A factory installed differential pressure sensor senses the

pressure differential across the filters. When the differential

pressure exceeds a user selectable setting will display a

diagnostic. The unit will continue to run until you replace

the air filters.

Supply Air Static Pressure High Limit

During normal operation, the Supply Air Static is monitored.

If at any time the static pressure exceeds the software high

static limit (defaulted at 2.0 inches from the factory) the unit

will immediately shut down and generate a diagnostic.

In order for the unit to resume operation, the Alarm Reset

must be toggled from the TD7. The software high static

limit can be user adjusted at the TD7.

Operating Principles

Loading...

Loading...