52

PKG-SVX027D-EN

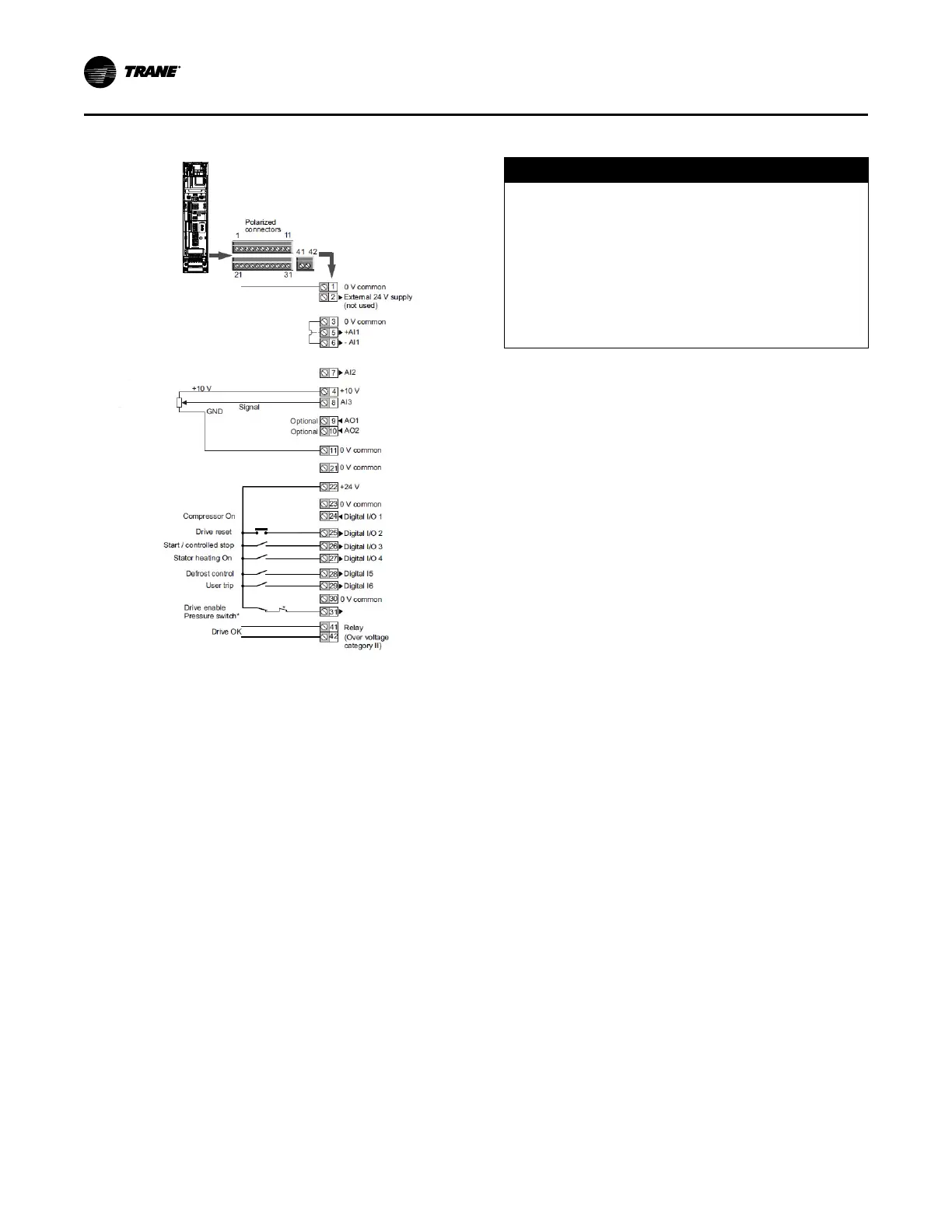

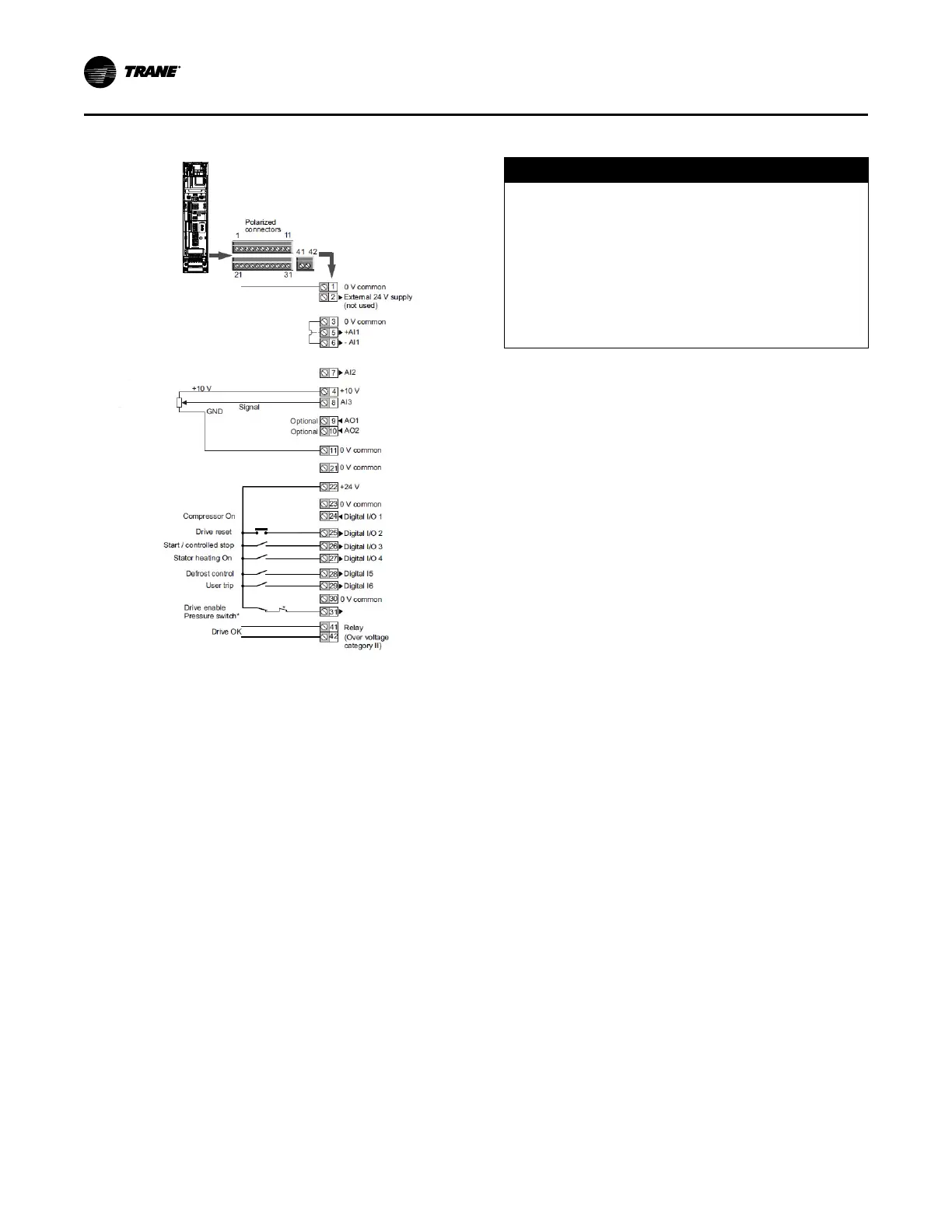

Figure 41. Variable speed compressor drive I/O

Compressor Staging

Fixed speed compressors cycle and the variable speed

compressor loads/unloads to maintain the operating state

required by the temperature controls. In the event of a

compressor failure, the next available compressor turns on.

During normal conditions, compressors will not turn on until

they have been off for at least three minutes. Normal

operating conditions are established on an individual

compressor basis. When a compressor starts, its timer also

starts.

Compressor Control

Steps of mechanical cooling are control based on supply

air or zone temperature. Compressor staging is based

upon a proportional, integrating (PI) control algorithm.

Waterside Components

Waterside components consist of water piping, water

valves, water flow switch option, water cooled condensers,

and the economizer option.

Water Purge

NOTICE

Proper Water Treatment Required!

The use of untreated or improperly treated water

could result in scaling, erosion, corrosion, algae or

slime.

Use the services of a qualified water treatment

specialist to determine what water treatment, if any, is

required. Trane assumes no responsibility for

equipment failures which result from untreated or

improperly treated water, or saline or brackish water.

Automatically circulate water through the economizer and

condensers periodically during non-operational times. This

allows fresh chemicals to circulate in waterside heat

exchangers. This feature is on all units and is controlled at

the HI.

Water Piping Options

Water piping is factory-installed with left-hand (standard)

and right hand (optional) connections on units. Also, units

with waterside economizers can be set for either variable or

constant water flow at the HI. See for detailed piping

configuration information.

With compatible piping configurations, the unit can be

configured to provide:

• Constant water flow with basic or intermediate piping

or

• Variable water flow (head pressure control)

Constant water flow is for condenser pumping systems that

are not capable of unloading the water-pumping system.

Variable water flow maximizes energy saving by unloading

the water pumping system.

Basic Water Piping

This option is available on units without a waterside

economizer and with condenser water applications above

54°F (12.2°C) that do not require condensing pressure

control. Left hand water connections and piping are

extended to the unit exterior. Manifold piping is factory

installed.

Water Regulating Valve (WRV) optional

If equipped, each compressor (Fixed or VS) uses a 24 Vac

powered water regulating ball valve to control flow through

the condenser. The UC600 controller modulates the

condenser flow to limit discharge pressure, help prevent

high pressure cutout trips, and maintain a compressor

minimum differential pressure.

The valve can also be used for condenser system chemical

purge and condenser cooling loop system balance.

Water Flow Switch Option

A water flow switch is required to be installed in the

condenser water pipe within the unit; it can be supplied

Operating Principles

Loading...

Loading...