PKG-SVX027D-EN

51

It will annunciate either High Pressure Cutout Compressor

X or Compressor Safety Circuit X.

Variable Speed Compressor (VS)

The VS compressor does not have an external crankcase

heater (like FS compressors). Instead, whenever the VS

compressor is off, the VS drive applies a voltage to the

compressor motor stator such that the compressor doesn't

rotate but heats the oil.

The VS drive, 1U1, has its own software to control and

protect the VS compressor. See Figure 41, p. 52 for VSD

Input/Output terminals.

The drive receives the following signals from the Unit

Controller:

• Controlled Start/Stop

• Speed signal

• Drive Reset

• Stator Heat Enable

• Emergency stop

Note: The 24 Vdc voltage used in each of the circuits

above -except the speed signal-originate from the

VS drive.

The drive provides the following signals to the Unit

Controller:

• Compressor On status

• Drive Fault status

Upon a call for mechanical cooling, the Unit Controller

issues the command to start the compressor via a dry

contact closure on XM32.3. When the 1U1 drive receives a

Controlled Start signal it runs the compressor at 3600 rpm

for 60 seconds. The compressor then runs at whatever

speed commanded by the Unit Controller. Similarly, when

the 1U1 drive receives a Controlled Stop signal it runs the

compressor at 3600 rpm for 60 seconds then turns the

compressor off.

The VS compressor HPC is wired in series with the 1U1 E-

stop circuit. A VS compressor HPC event or upon a Unit

Controller remote Emergency Stop input will immediately

stop the VS compressor and lockout its operation on a

manually resettable diagnostic.

Compressor Limit Conditions

Because the MSC uses suction and discharge pressure

sensors rather than limit switches, the Unit Controller can

sense when a refrigerant circuit is approaching a high or

low pressure limit condition.

Low Pressure Limit conditions can be caused by the

following:

• Low discharge air temperature

• Low airflow

• Dirty air filters

• TXV malfunction

• Low refrigerant charge

• Faulty suction pressure sensor

High Pressure Limit conditions can be caused by the

following:

• Low condenser water flow

• High entering condenser water temperature

• Fouled entering condenser water strainer

• TXV malfunction

• Refrigerant over charge

• Water regulating valve (WRV) malfunction

• Faulty discharge pressure sensor

The Unit Controller's TD7 will annunciate a Limit Condition

if an FS compressor circuit enters one. If the unit is

equipped with WRV, the Unit Controller can open the valve

to allow more flow through the condenser to help mitigate

HPC trip.

If the VS circuit enters either a High or Low Pressure limit

condition the Unit Controller can reduce compressor speed

to help mitigate either a Low or High pressure diagnostic

trip.

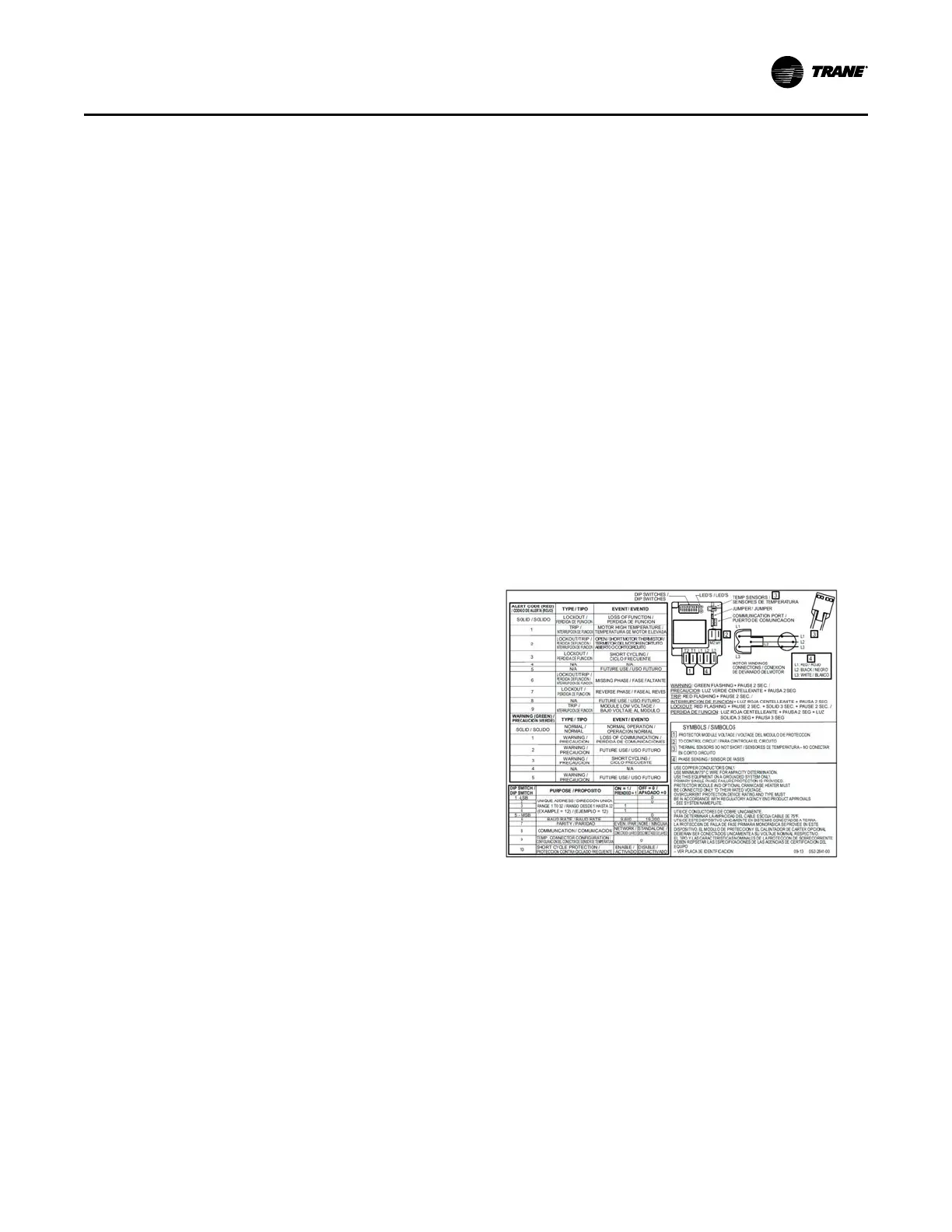

Figure 40. Fixed speed compressor protection

module (MCSP)

Operating Principles

Loading...

Loading...