23

10.2016

WTAL - TNX65/42

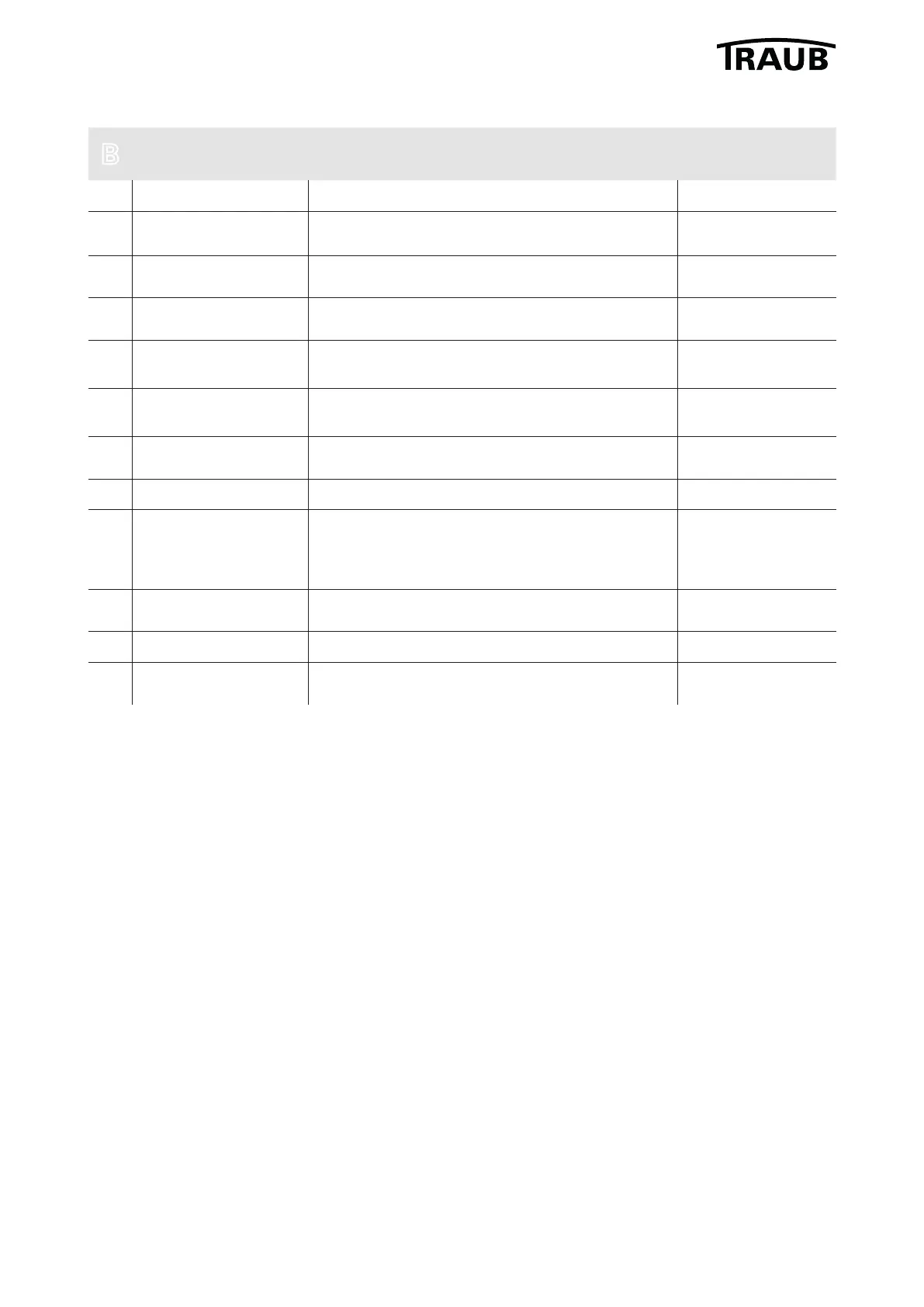

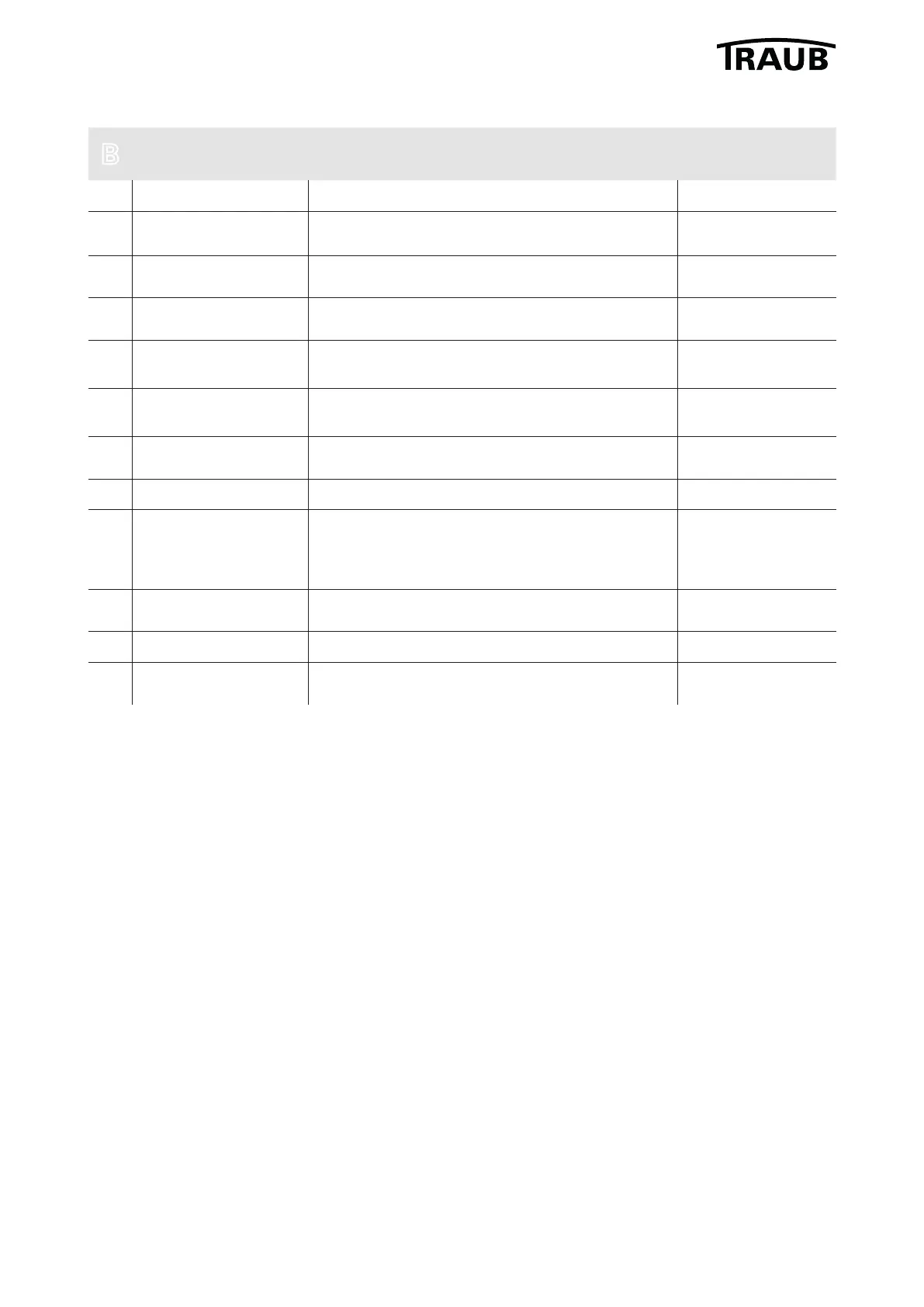

Maintenance work every 200 hours of operation

B

Maintenance work every 200 hours of operation

No. Where What Comments

01 Hydraulic system • Check system pressure

• Check oil level

02 Chip conveyor • Check the chip conveyor for fouling around the

level switch and clean it if necessary

Note manufacturer's

documentation

03 Central lubrication

unit

• Check filling level

04 Pneumatic system • Check filter for fouling and replace if necessary

• Check and correct the air pressure if necessary

05 Power clamping

chuck

• Clean and lubricate Note manufacturer's

documentation

06 Parts conveyor • Check belt of parts conveyor Note manufacturer's

documentation

07 Lighting • Check and clean/repair if necessary

08 Transition from

working area to

coolant / oil spray

extractor

• Clean

09 Covers in the working

area

• Check wiper / wiper lips Switch on the

machine

10 Fluid cabinet • Clean the metal filter

11 Bar feeding magazine • Check oil level Note manufacturer's

documentation

Loading...

Loading...