44

10.2016

WTAL - TNX65/42

Maintenance work every 2 000 hours of operation

Ball screw transmission, X-axis, Z-axis, V-axis and Y-axis

Determine the reversing backlash

This maintenance work can only be carried out when the machine is

switched on.

The machine must have run up for at least three hours (displace all

axes) before checking the reversing backlash!

The distances traversed in order to measure the reversing backlash must be

specified by a CNC program, not via the handwheel!

Moreover, the Z-axis should be set near the machining position,

since the reversing backlash does not remain constant over the entire Z-axis!

D05

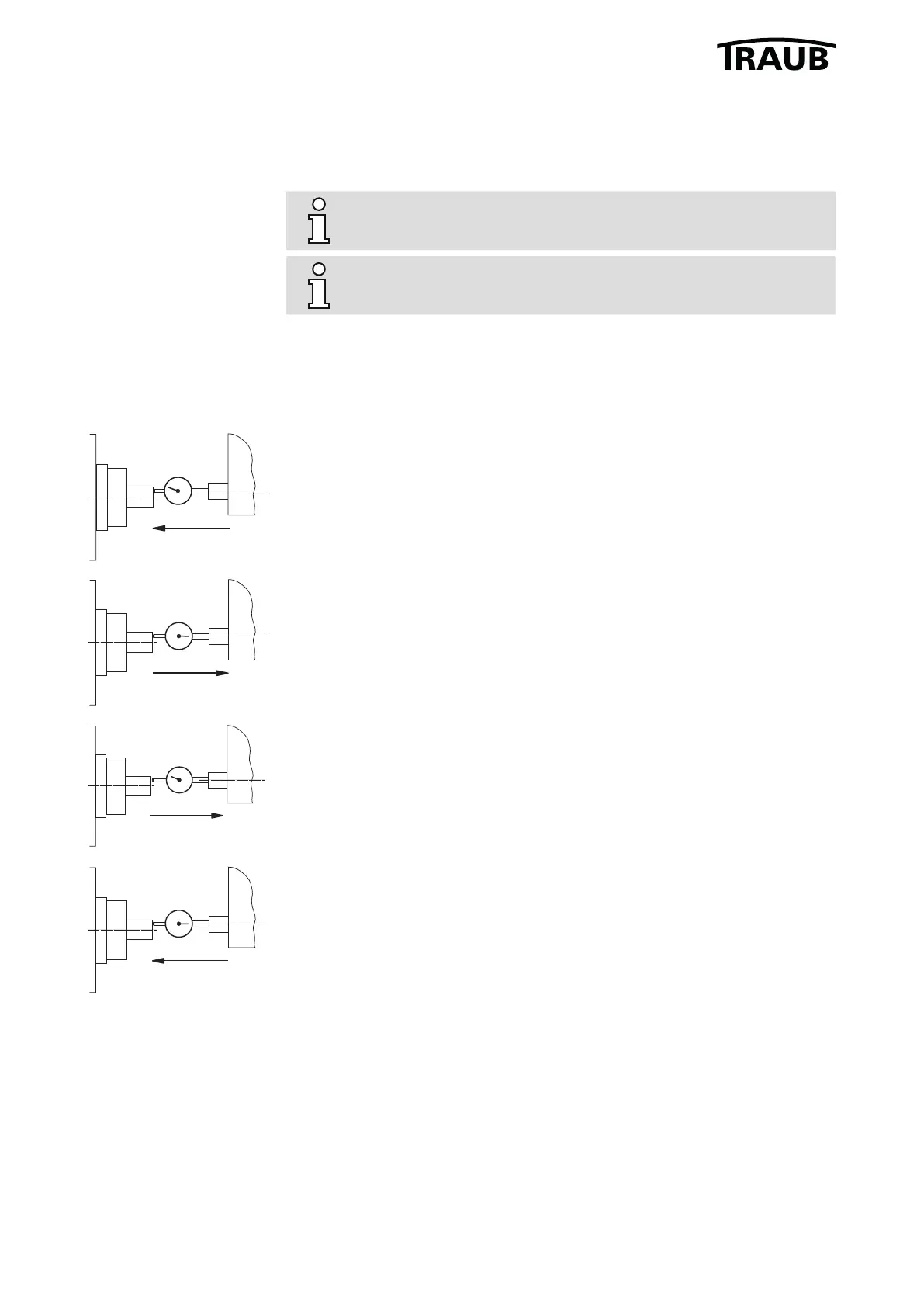

• Clamp a faced round part in the collet or jaw chuck.

• Secure a dial gauge with a resolution of 1/1000 on the tool carrier.

• Approach the clamped turned part until the tracer pin is just short of the

fixed stop (feed rate f = 200 mm/min.).

• Retract the carriage until the dial gauge pointer is within the indicating range

(f = 150 mm/min.).

• Set the dial gauge pointer to "0".

0

50

25

75

Approach

0

50

25

75

Retract (half the

measuring range)

• Retract the carriage by 3 mm (dial gauge cleared)

(f = 150 mm/min).

0

50

25

75

Retract 3 mm

• Advance the carriage 3 mm to the zero position

(f = 150 mm/min.).

• Read off and note the value on the dial gauge (every value

other than "0" equals the reversing backlash).

• Repeat this measurement five times and form a mean value.

• This mean value must be doubled and entered in the control

system as a backlash compensation value.

• Check the measurement.

If the values for the reversing play of the X, Z, V and Y axes are greater than

0.01 mm, they must be corrected by the machine manufacturer's service.

0

50

25

75

Approach 3 mm,

read off value

Loading...

Loading...