22

Connecting the battery

Liquid electrolyte batteries must be installed in a separate box

with ventilation leading to the outside. The fuse in the positive

lead must be connected outside the box. A separate box is

not required for gel or AGM batteries. Pay attention to the bat-

tery manufacturer’s installation instructions.

The outgoing lines from the terminals must be routed with a

gap between them until after the fuse in the positive lead.

+

-

+

-

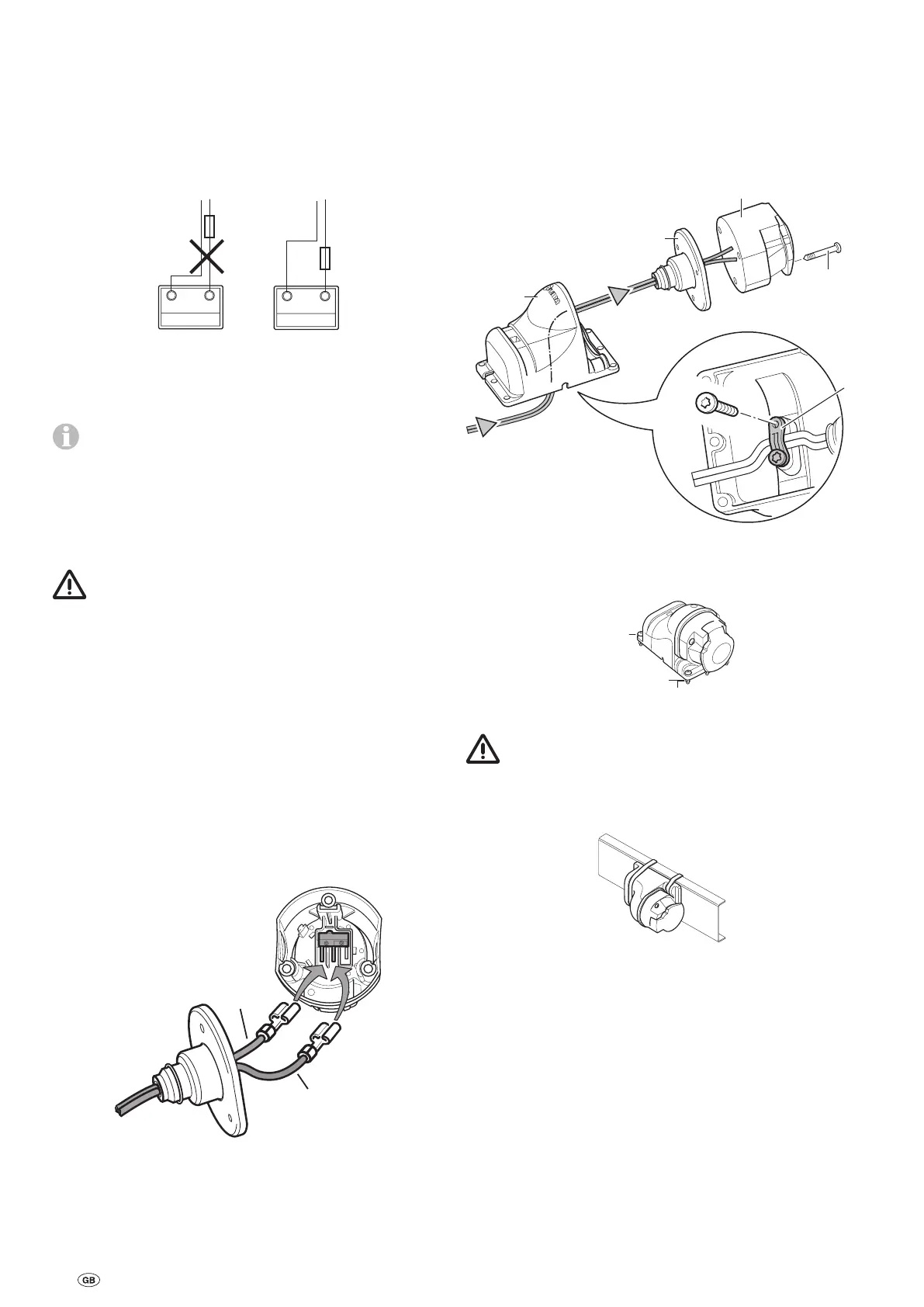

Fig. 19

Route the battery connector cables (only use the original

Truma cables supplied) to the control unit and attach them

securely using the clips and screws provided.

The battery connector cables must not be extended.

They must be routed separately from the motor cables,

and must not run over the control unit.

Route battery connector cables so that they do not chafe (par-

ticularly at leadthroughs through metal panels). Use suitable

protective leadthrough bushing to prevent damage to cables.

Connect battery connector cables to the existing battery ter-

minals (red = positive, black = negative).

Incorrect polarity will destroy the electronics/control

unit.

The connection to the control unit (as per the connecting

diagram) must be made in the order: nut, battery connection

ring eyelet, nut (torque M6 = 6 Nm).

Connect fuse in the positive lead (150 A) near the positive

terminal.

Connecting the safety socket

Lead the provided 2-wire cable with the flat connectors

through the socket holder (g) and the rubber sleeve (h).

If necessary, open cover and push socket connection out of

socket housing (i).

Connect 2-wire cable with flat connectors to micro switch.

RD / BK

BK

Fig. 20

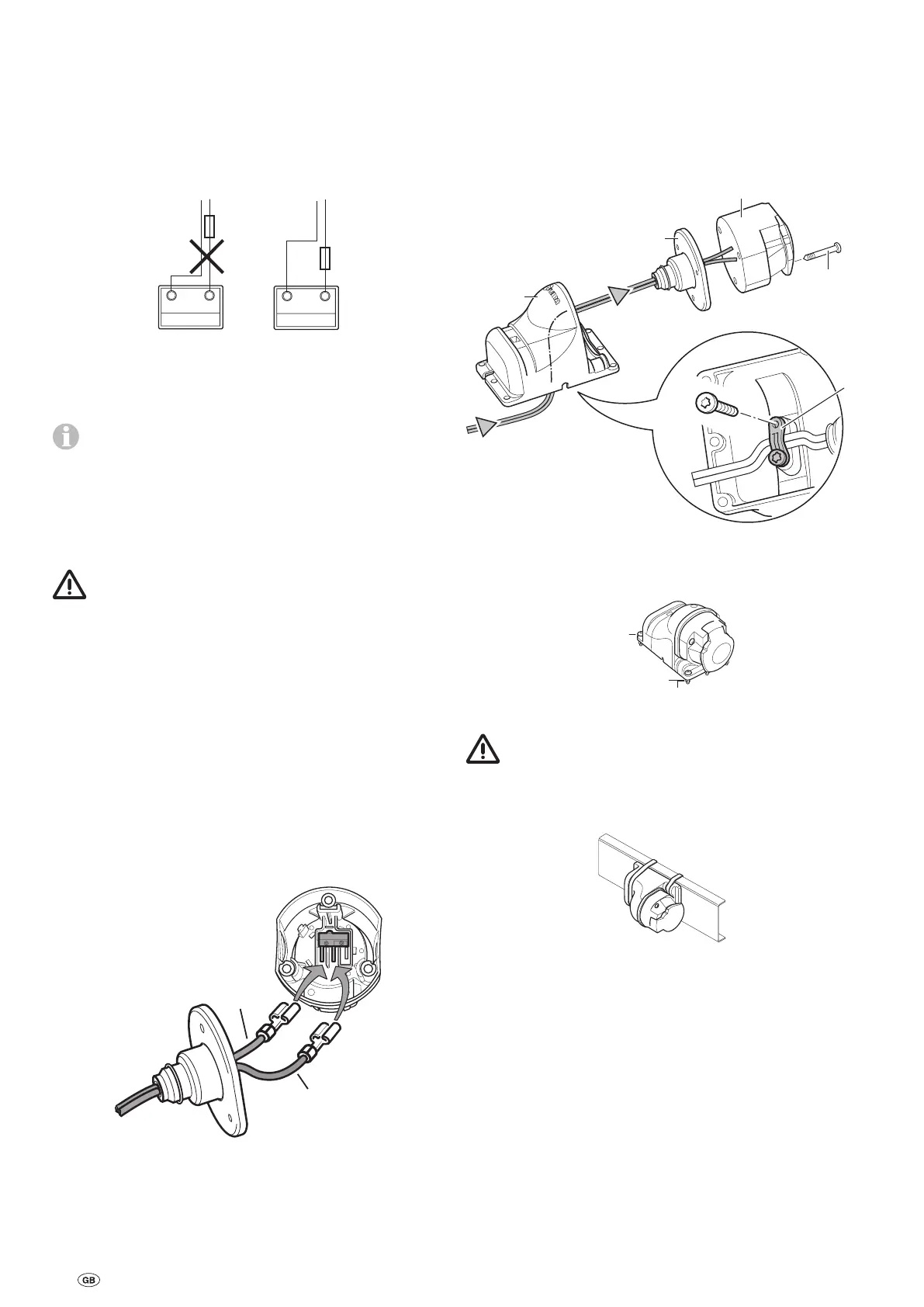

If necessary, insert socket connection back into socket hous-

ing (i).

Screw socket housing (i) to socket holder (g) using 3 sheet

metal screws (j). (Several positions are possible by selecting the

mounting holes at the socket holder and rotating the rubber

seal)

Lead cable loosely through the strain relief (k) and screw in

place with the 2 sheet metal screws. Depending on the instal-

lation situation, the cable can be led out of the socket holder

through one of the three recesses.

j

(3 x)

h

g

PT 4 x 10

k

Fig. 21

Secure safety socket to the (plastic) shaft cover of the caravan

with 4 screws, nuts and washers.

M4 x 16

(4 x)

Washer 4.3

Fig. 22

No holes must be drilled in the chassis.

Alternatively, the safety socket can be secured using the two

clips.

Fig. 23

Route both wires to the control unit (shortening them if neces-

sary) and connect them to the connector block as shown in

the connecting diagram.

Re-check whether all cables are correctly connected, attached

using the provided clips and cannot chafe.

Loading...

Loading...