V02.00 | 2019/10

119

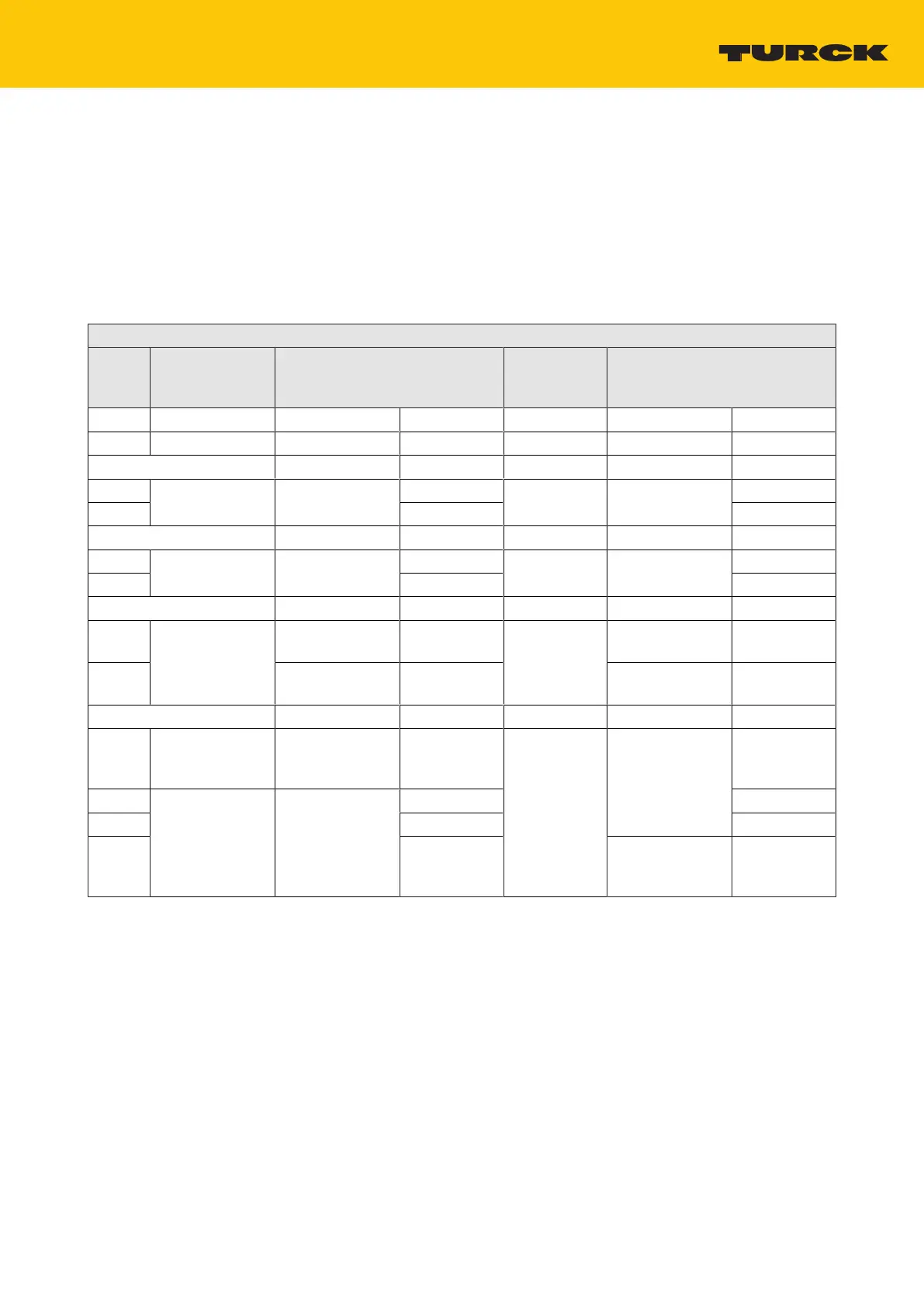

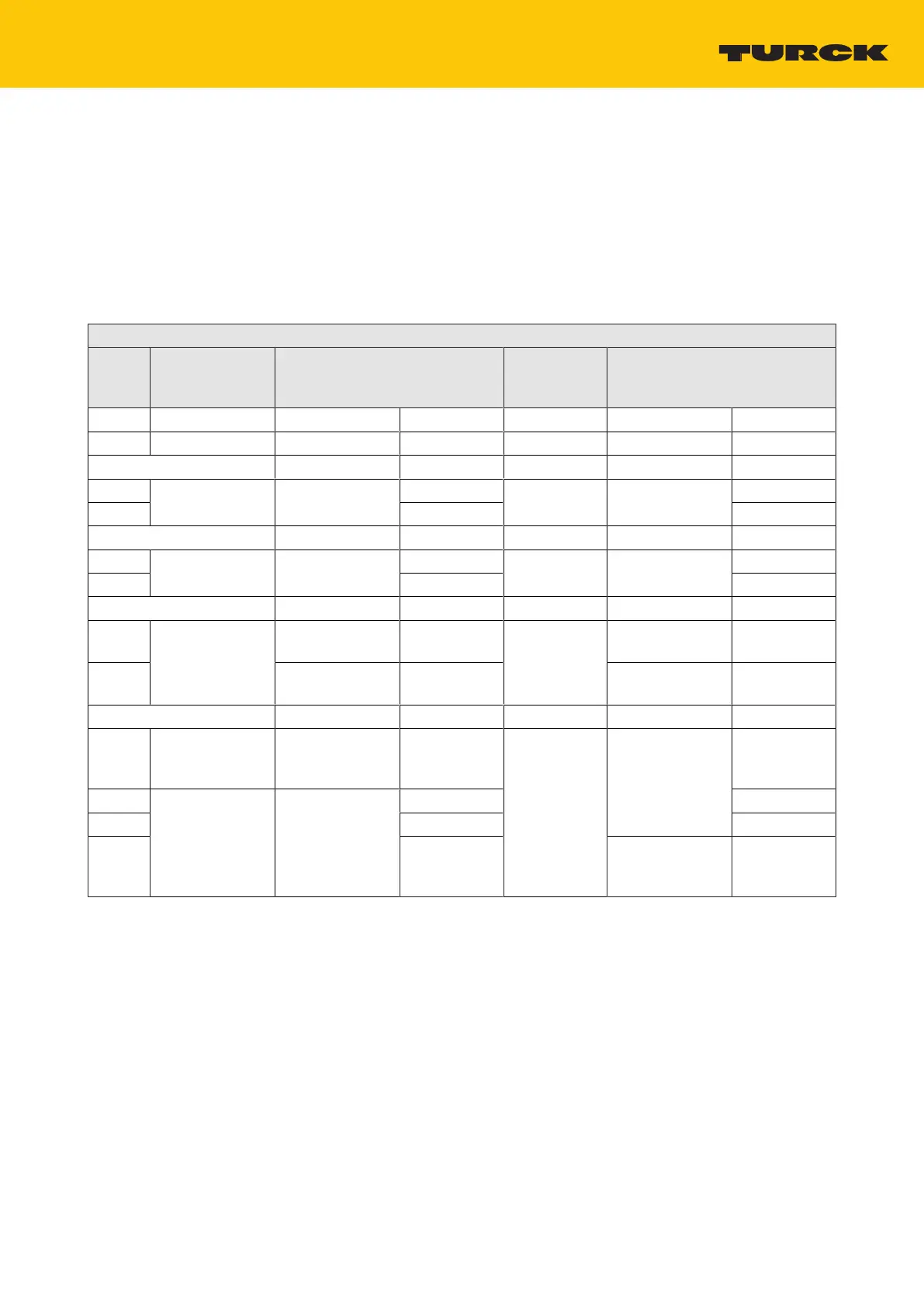

9.1.1 Adapting process data mapping

The mapping of process data can be adapted application-specifically via the IO-Link master's

parameterization.

Depending on the used fieldbus, it can be necessary to swap process data word-wise, double

word-wise or completely in order to align them to the data structure in the PLC. The process

data mapping is determined channel by channel through the parameters process input data

mapping and process output data mapping.

Example mapping for field buses with Little Endian-format:

Mapping through the IO-Link master

Ò

field bus

Ò

PLC

Byte Device at

IO-Link port

Device process data in

IO-Link master

Parameter:

Process data

mapping

Device process data to field bus

Byte 0 Status Status

Byte 1 Control Control

IO-Link port 1

Byte 2 Temperature

sensor TS…

Temperature Low byte

swap 16 bit

Temperature High byte

Byte 3 High byte Low byte

IO-Link port 2

Byte 4 Linearity sensor

Li…

Position Low byte

swap 16 bit

position High byte

Byte 5 High byte Low byte

IO-Link port 3

Byte 6 I/O hub TBIL-… Digital

signals

0…7

Direct

Digital signal 0…7

Byte 7 Digital

signals

8…15 Digital signal 8…15

IO-Link port 4

Byte 8 Diagnostics

swap all

Counter/position

value

Most

Significant

Byte

Byte 9 Rotary encoder

RI…

Counter/position

value

Low byte High byte

Byte 10 High byte Low byte

Byte 11 Most

Significant

Byte

Diagnostics

Loading...

Loading...