RAPTOR Hydro

3.5.8 Service and Parking Brake Adjustment

If you are not sufficiently manually skilled, have the operations done by an authorized service centre.

Functionality check:

1. Switch the bypass lever to the manual regime of the travel – see chapter 3.4.2.1 Switching between the Manual and

Motorized Travel.

2. Press the brake lever towards the handle until it is stopped by the handle and try to manually move the machine.

3. If it is possible to move the machine, it is necessary to adjust the brake.

The tension of the Bowden is adjusted with the expansion adjustment fitting by the lower end of the Bowden.

1. Loosen the both nuts – spanner No. 10. Caution – the nut by the notch has got left-oriented thread so it must be loosened in

the clockwise direction.

2. Turn the middle part of the expansion fitting by about one turn in the clockwise direction, which tightens the brake cable.

3. Without pressing the brake lever, test whether it is possible to easily move the machine. Press and lock the brake lever and try to

move the machine again. If it is not possible to move the machine, the brake works well again.

4. Tighten the both nuts. Caution – the nut by the notch has got left-oriented thread so it must be tightened in the counter-

clockwise direction.

3.5.9 Checking tightening of screwed connections

Besides the other screwed connections, regularly check that handlebars joint nuts are tightened – see

Fig. 3

on page

92

. There should

not be any vertical clearance on the joint. The side adjustment of the handlebars should not be easy in terms of the force needed to

perform the action. Use the ring spanner or the socket 17 mm.

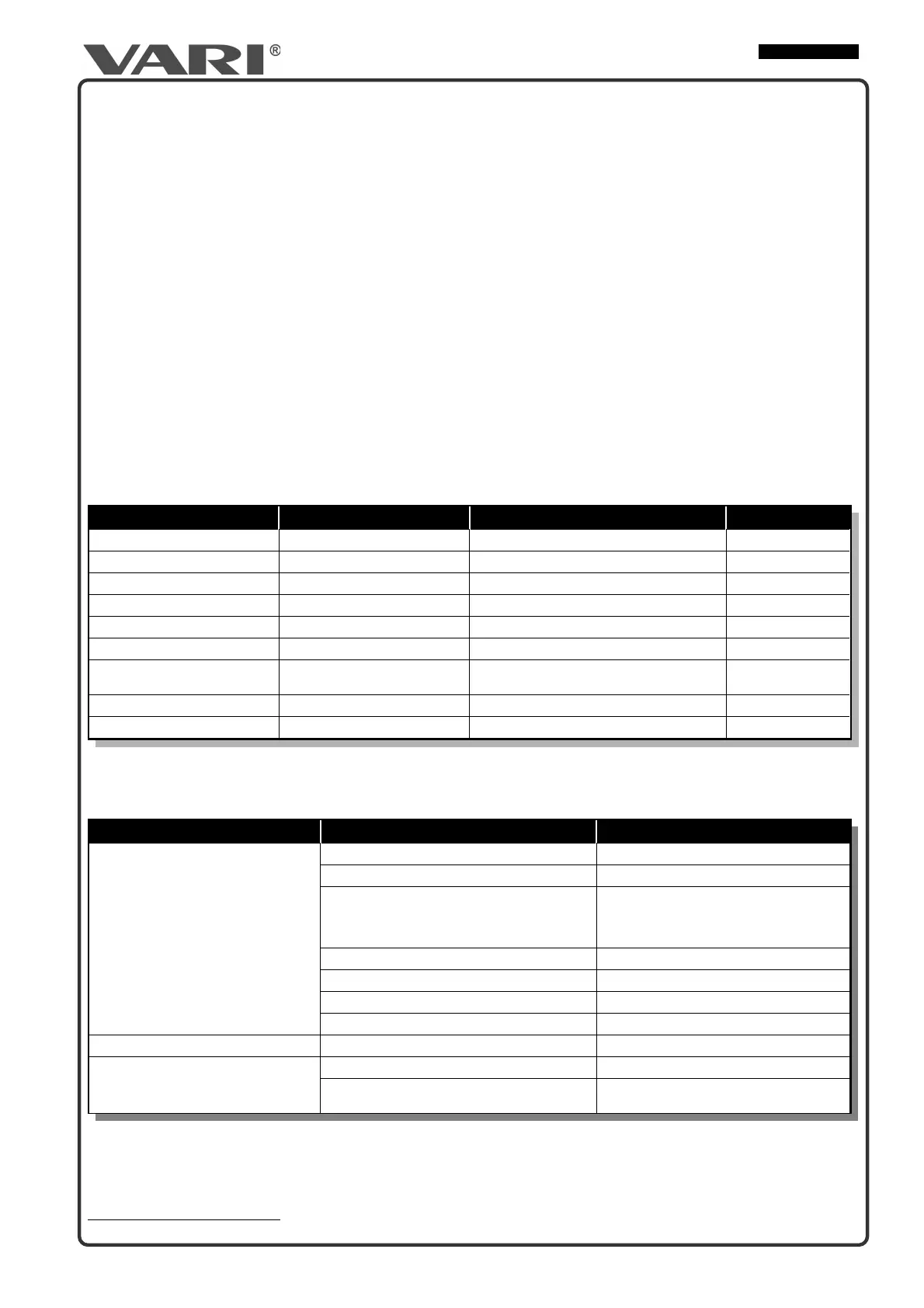

3.5.10 Servicing intervals

Activity Prior to each use During the season Prior to storing

Checking engine oil level yes, always - yes

Engine Oil Change - per the engine operating instructions -

Checking the gearbox oil level yes, always - -

Gearbox oil change - after the first 30 hours, then after every 100 hours -

Engine air filter cleaning check every 10 hours

75

yes

Washing - as needed yes

Checking tightening of screwed

connections

yes, always every 5 hours yes

Lubrication check of the condition Table 29 yes

V-belt check - every 20 hours yes

Table 39: Servicing intervals

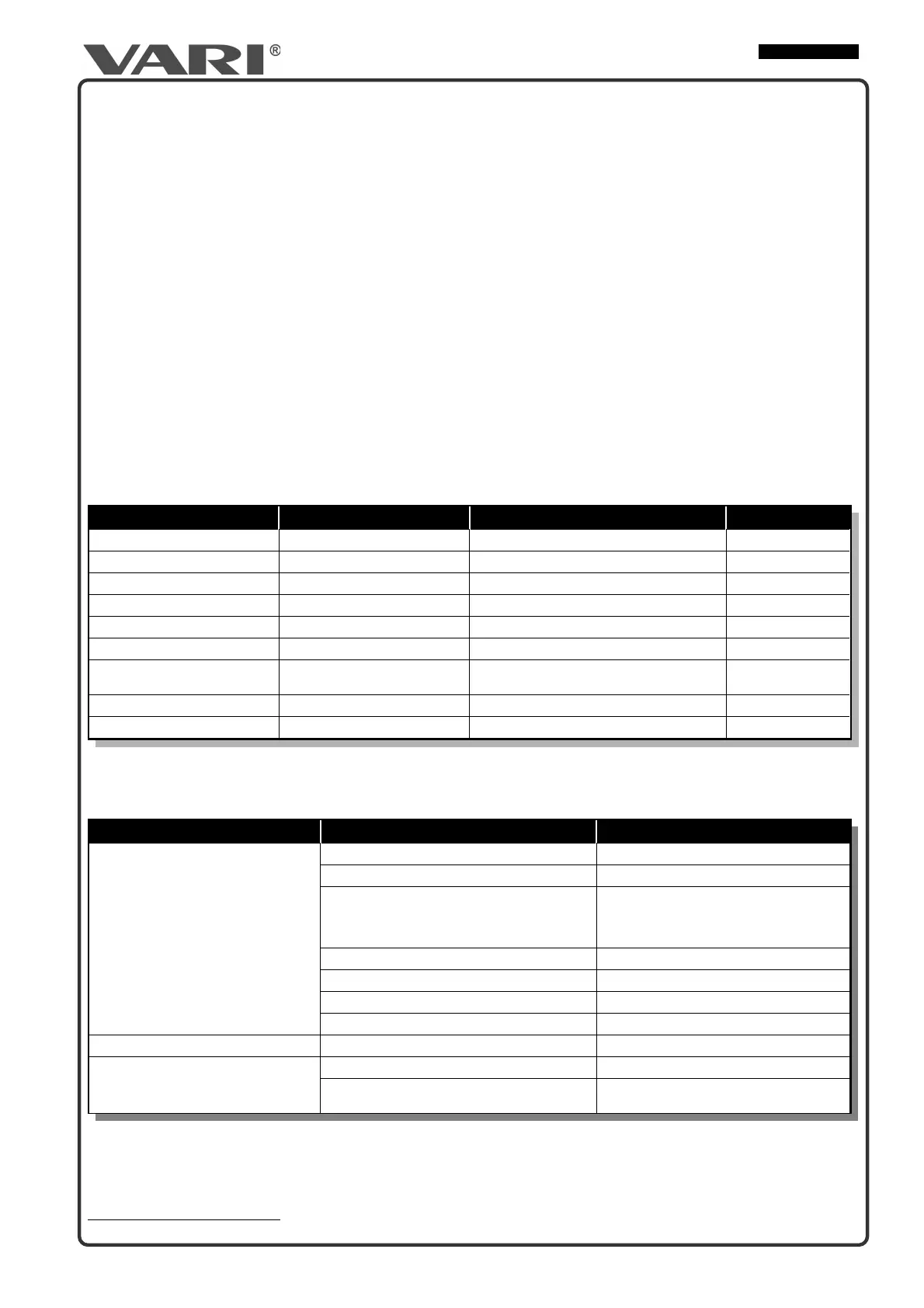

3.5.10.1 Troubleshooting

Problem Cause Solution

The engine will not start The petrol tanks are empty Add petrol

The petrol supply line is closed Open the petrol supply line

The cap bleeder is clogged Loosen the cap and try to start the engine; if the

engine ignites, tighten the cap and wait whether

the engine goes out; try to blow the pressurized

air to the cap through the holes.

The clutch plate carries away the carrier disc Visit a service facility

Non-functional automatic choke Visit a service facility

Defective spark plug Replace

Another engine defect Visit a service facility

The engine cannot be stopped Non-functional engine short-circuiting Turn off the fuel supply, visit a service facility

The engine lacks the power Clogged air filter Clean it or replace it for a new one

Another engine defect Turn off the engine immediately, visit a service

facility

75

In the event of a very dusty environment, the check and cleaning should be done every hour!

52

revize 11/2017

Loading...

Loading...