RAPTOR Hydro

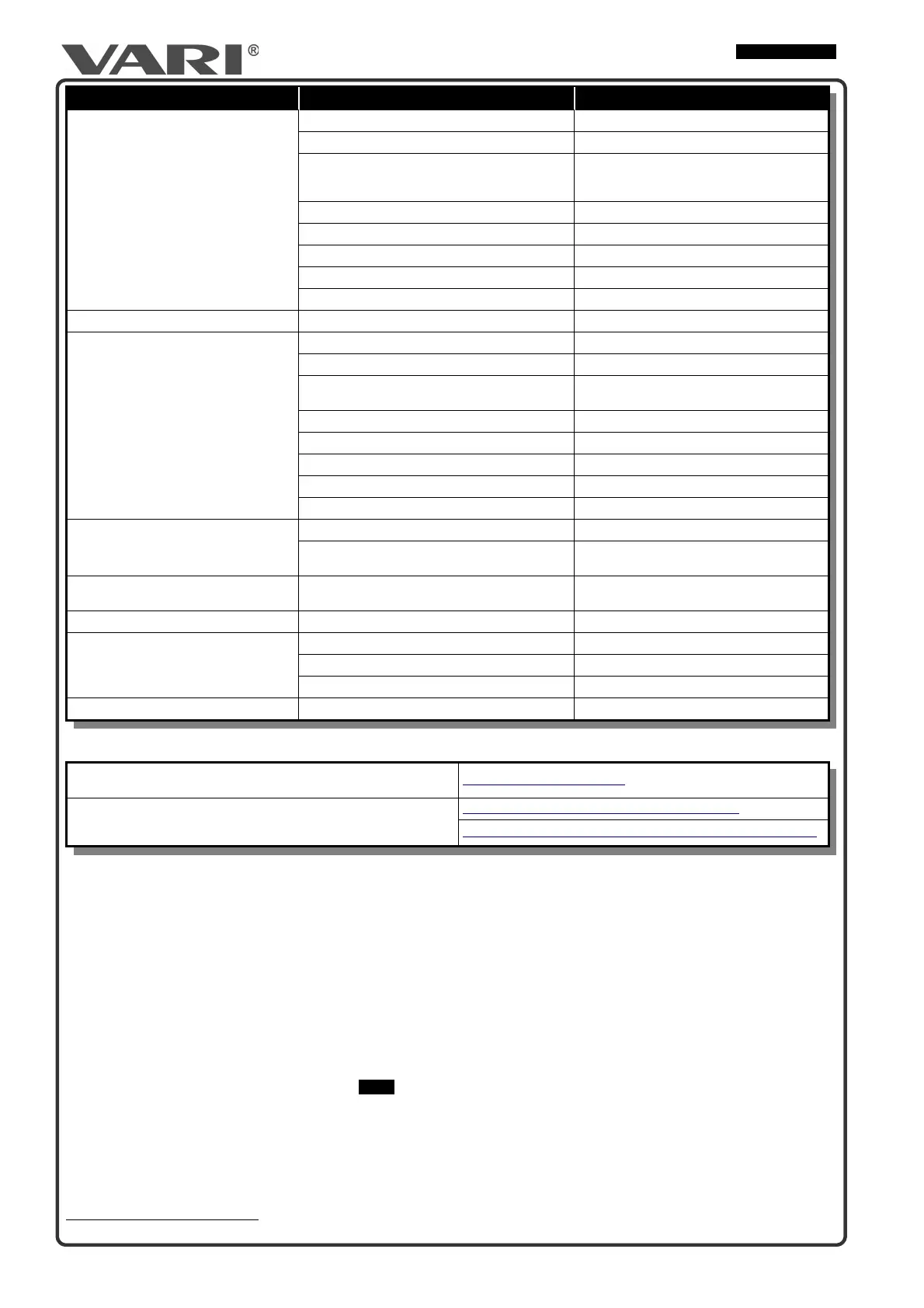

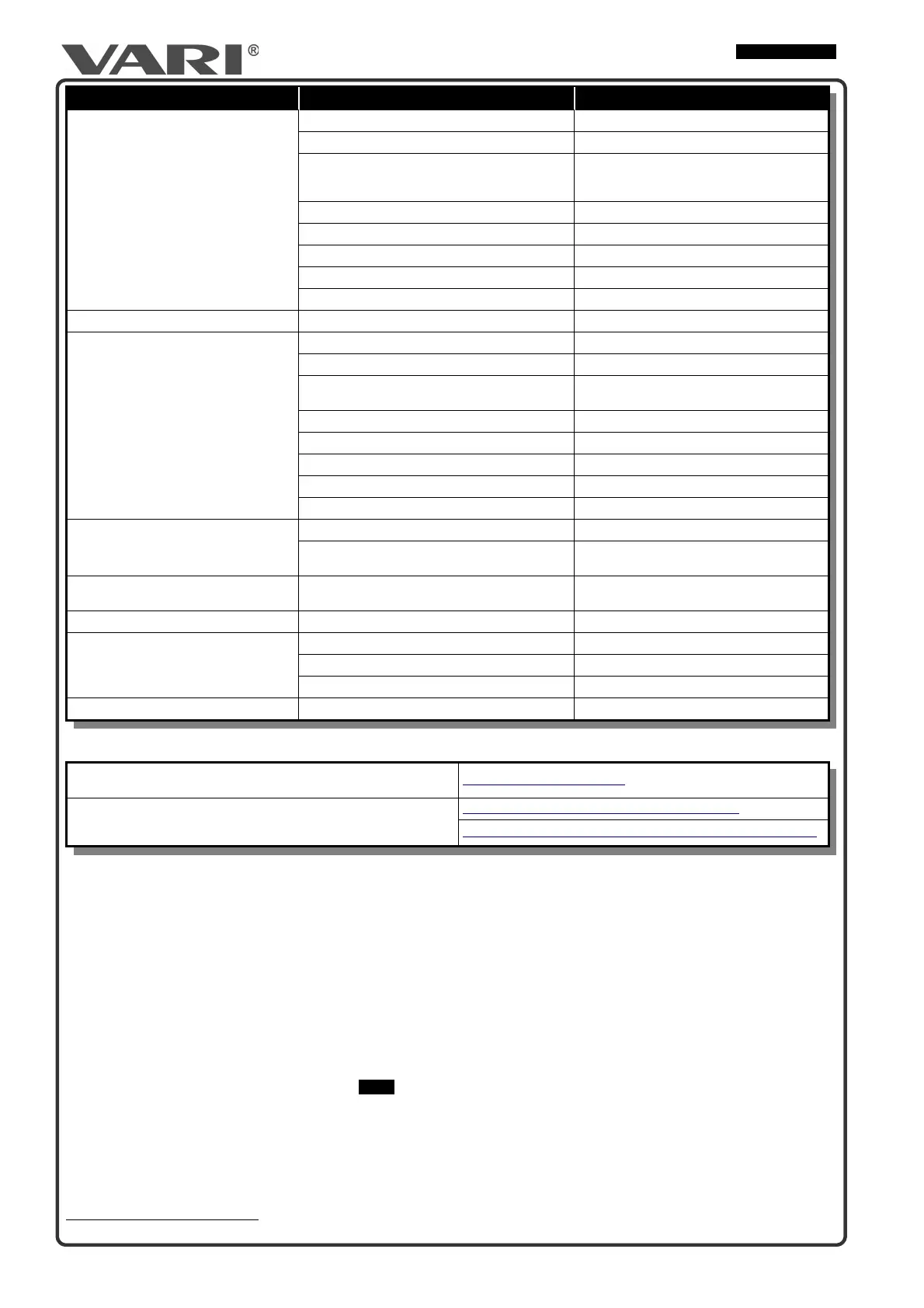

Problem Cause Solution

The work tool will not rotate The engine is not started Start the engine

The attachment drive clutch lever is not pressed Press the lever

The attachment drive belt pulley is not engaged Engage the pulley according to the instructions

contained in the operating instructions for the

attachment

The attachment drive belt is not tightened Adjust the tension pulley

Broken belt of the drive of the attachment Replace the belt

The belt of the drive of the attachment fell off Re-mount the belt

Broken attachment drive clutch cable. Visit a service facility

Other defect Visit a service facility

The revolutions of the work tool are dropping The clutch is slipping Adjust the clutch or visit a service facility

The machine is not moving The engine has not started Start the engine

The travel clutch lever is not pressed Press the lever

The bypass lever is in the position enabling the manual

travel.

Move the lever to the position for the engine-

powered travel.

Insufficient belt tension Adjust the tension pulley

Torn belt Replace the belt

The belt has come off Re-mount the belt

Broken attachment drive clutch cable. Visit a service facility

Other defect Visit a service facility

The machine travel will not stop The tension pulley does not return back to its position Lubricate

The inner Bowden cable is stiff; bent Bowden cable Lubricate or replace the Bowden cable (visit a

service facility)

The machine is moving even when the lever is

in the neutral (N) position

The neutral position of the gearbox control lever is

moved.

Adjust the bowden or visit a service facility

The attachment drive will not stop Blocked up clutch Visit a service facility

The control levers do not return back. The inner Bowden cable is stiff; bent Bowden cable Lubricate or replace the Bowden cable

Broken return spring Replace with a new one

Other defect Visit a service facility

Other defect Visit a service facility

Table 40: Troubleshooting

In the event of problems with the gearbox, visit the gearbox manufacturer’s

web pages for more information

http://www.tufftorq.com/support/

In the event of any problems with the engine, visit the web page of the engine

manufacturer or contact an authorized service centre for Briggs&Stratton

engines

https://www.briggsandstratton.com/eu/en_gb/home.html

https://www.briggsandstratton.com/eu/en_gb/support/dealer-locator.html

Table 41: Technical support links

76

3.5.10.2 Storage

Before storing the machine for a longer time, we recommend to do the following:

Remove any dirt from the machine.

Repair any paint damage.

Drain the fuel from the fuel tank and carburettor (further instructions in the engine operating instructions).

Lubricate the machine as recommended, see

Table 29

.

Check the tyre pressure and inflate the tyres to MAX value. Treat the tyres with a suitable preparation for protection and renovation

of the rubber parts of the tyres.

Prevent unauthorized persons from access to the machine. Protect the machine against climatic conditions but do not use impermeable

protection to prevent excessive corrosion it may cause.

76

The internet inks were up-to-date as of 27 July 2017. After this date, the functionality of the links cannot be guaranteed.

53

revize 11/2017

Loading...

Loading...