Vertiv | Liebert® CRV4 | User Manual 96

System Operation and Maintenance

8.9. Refrigerating System Maintenance

Following are the basic instructions relevant to the maintenance of the refrigerating system:

1. Check the refrigerating system once a month to ensure the system is functioning perfectly.

2. Perform a visual check for detecting signs of wear and tear.

3. Regular inspection is a good practice to ensure long service life of the refrigerating system.

4. Check the refrigerant piping once every 6 months to ensure that there is no wear and tear.

8.9.1. Suction Pressure

The compressor may stop when the suction pressure drops below the setpoint of the low pressure switch.

On the other hand, too high suction pressure will undermine the cooling eect of the refrigerant on the

compressor motor, leading to the damage of the compressor. The minimum (pressure switch action setpoint)

and the maximum (design operation value) suction pressures are listed in Table 8-3.

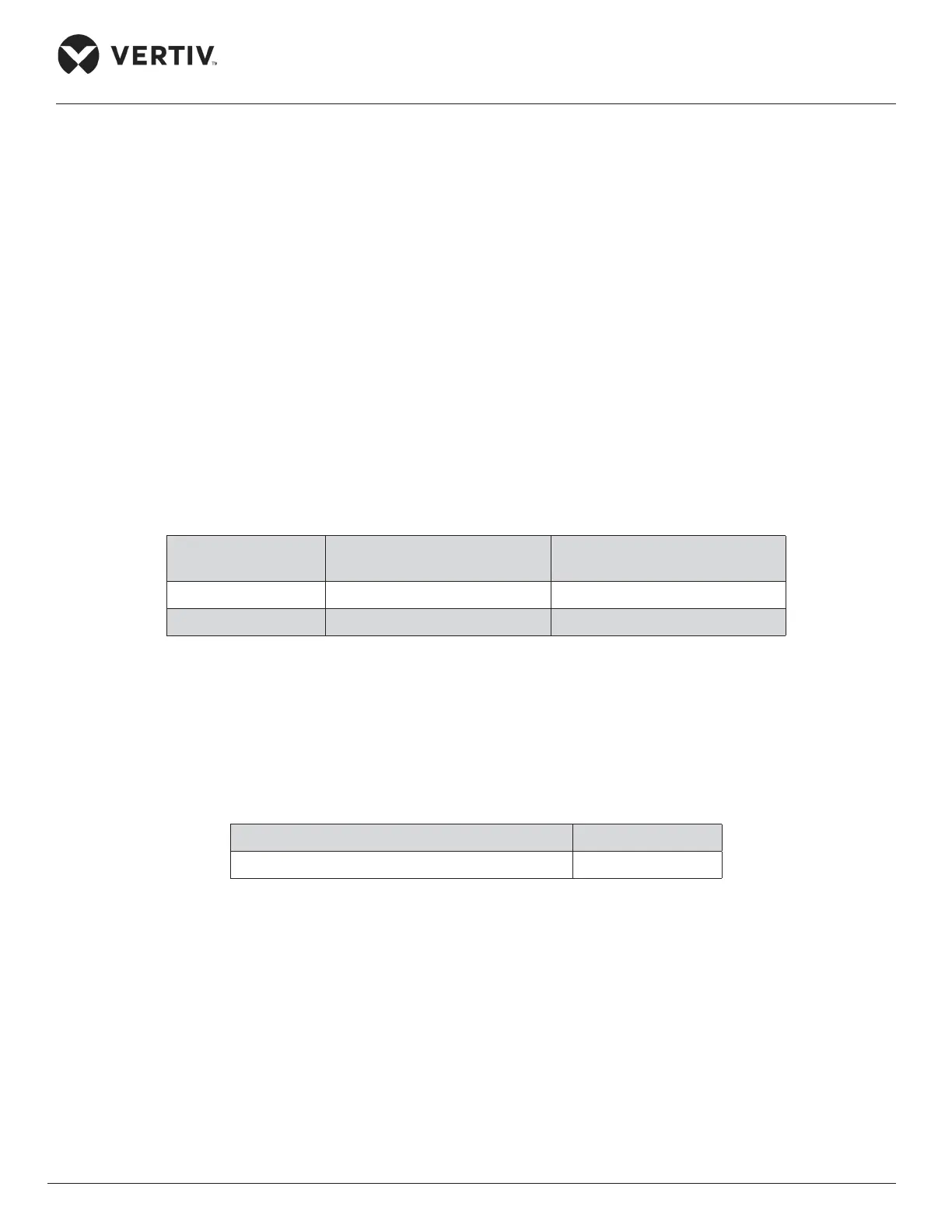

Table 8-3 Suction Pressure

System

Minimum Pressure, R410A

kPa

Maximum Pressure, R410A

kPa

CR025 4.5 12.4

CR035, CR045 4.5 13.4

8.9.2. Discharge Pressure

The discharge pressure may change with the load or the condenser eiciency. When the discharge pressure

increased to the setpoint of the pressure switch, the high pressure switch stops the compressor. See Table 8-4

for details.

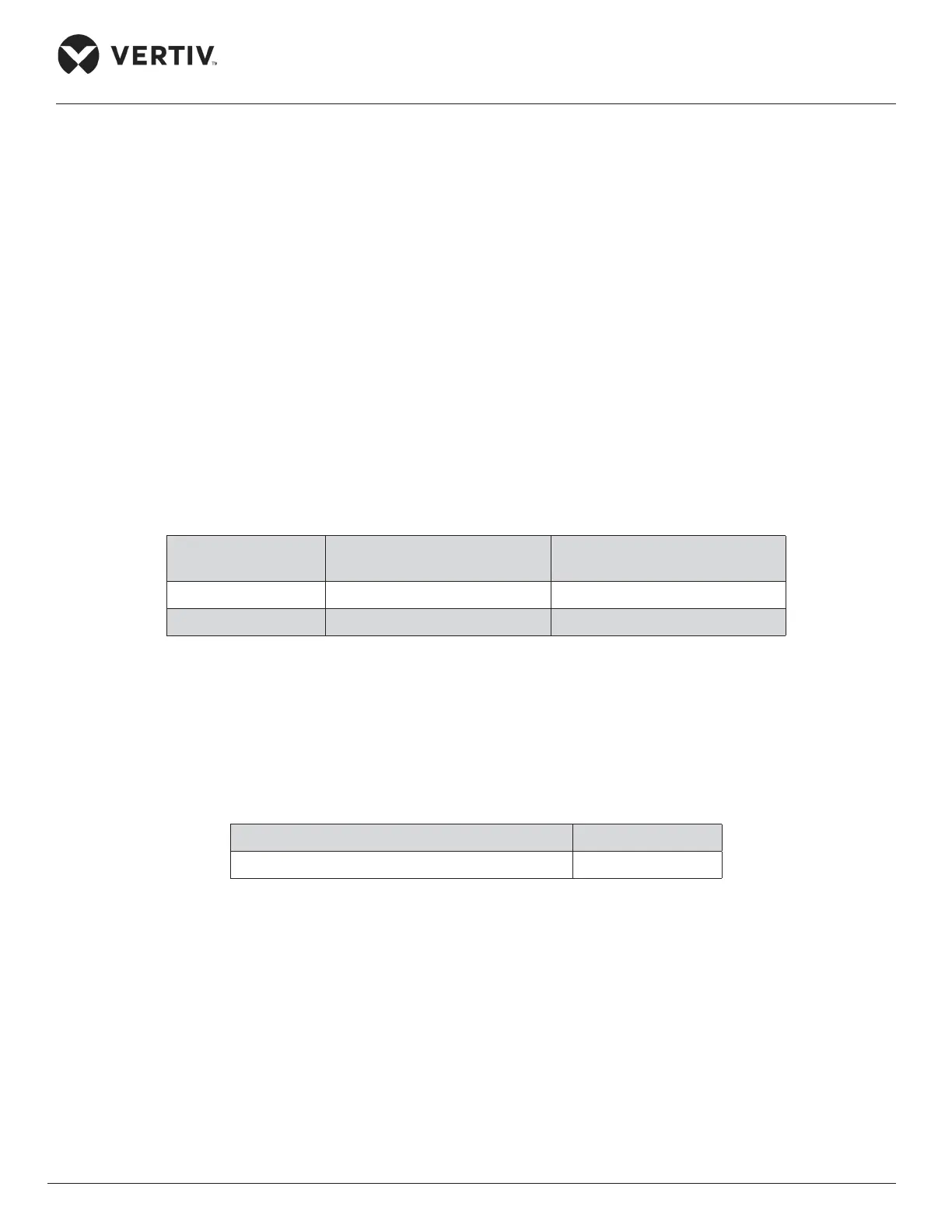

Table 8-4 Discharge Pressure

System Design kPa (PSIG)

CR025, CR035, CR045 3900

8.9.3. Electronic Expansion Valve (EEV)

The automatic regulation of the electronic expansion valve ensures that the evaporator is supplied with

suicient refrigerant to meet the load conditions. By measuring the degree of superheat, it can verify whether

the operation of the electronic expansion valve is normal. If the amount of refrigerant supplied to the evaporator

is too small, the air suction superheat will be high; if too much amount of refrigerant is supplied to the

evaporator, the air suction superheat will be low.

Loading...

Loading...