33

NM & PG PLUS FID STATIONS

USER MANUAL

Version 1.03.0000

www.vicidbs.com

11. MAINTENANCE

With proper care and maintenance, your hydrogen generator should provide you with years of trouble-free

operation. No adjustments need to be made to the generator. The only routine service operations are those

described below.

Nonetheless, the generator should be inspected approximately every 2 years. Contact your supplier.

11.1. ROUTINE MAINTENANCE - HYDROGEN PART

The following section describes the maintenance operations required for the correct operation of the

hydrogen generator.

The routine maintenance consists of:

• Fill the external water tank with distilled or deionized water

• Replace the deionization bag every 6 months or earlier if required

• Replace the water lter (inside the external tank) every 3 years

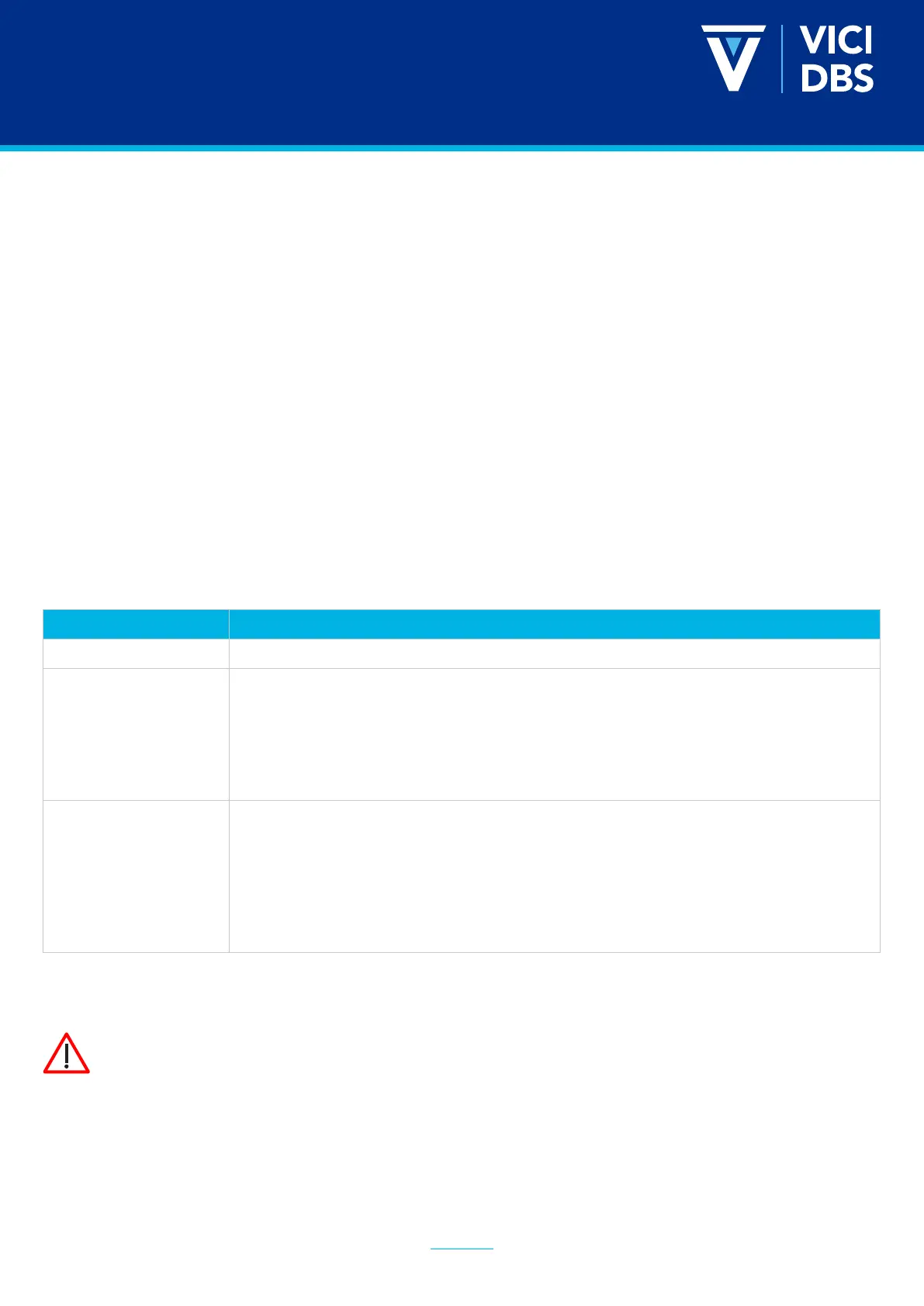

PART NUMBER DESCRIPTION

DB-H200-031 Deioniser bags (pack of 2)

DB-10428 3-year maintenance kit for NM Rack/FID-T/FID-S without air lter, contains:

• Deionizer LE bag (pack of 2)

• Perma pure dryer tubing (1)

• Filter element

• GLS service kit

• Water pump circulation

DB-10283 3-year maintenance kit for NM Rack/FID-T/FID-S with air lter, contains:

• Deionizer LE bag (pack of 2)

• Perma pure dryer tubing (1)

• Filter element

• GLS service kit

• Circulation pump

• Replacement cartridge for coalescent lter

11.2. ROUTINE MAINTENANCE - ZERO AIR PART

WARNING: Before service is performed, make sure that the system has been shut

down according to the instructions above.

1. Supply air pressure has been shut off with an in-line valve.

2. Line pressure has been released with an in-line relief valve.

3. Unit has been shut-off and isolated from electrical power.

Loading...

Loading...