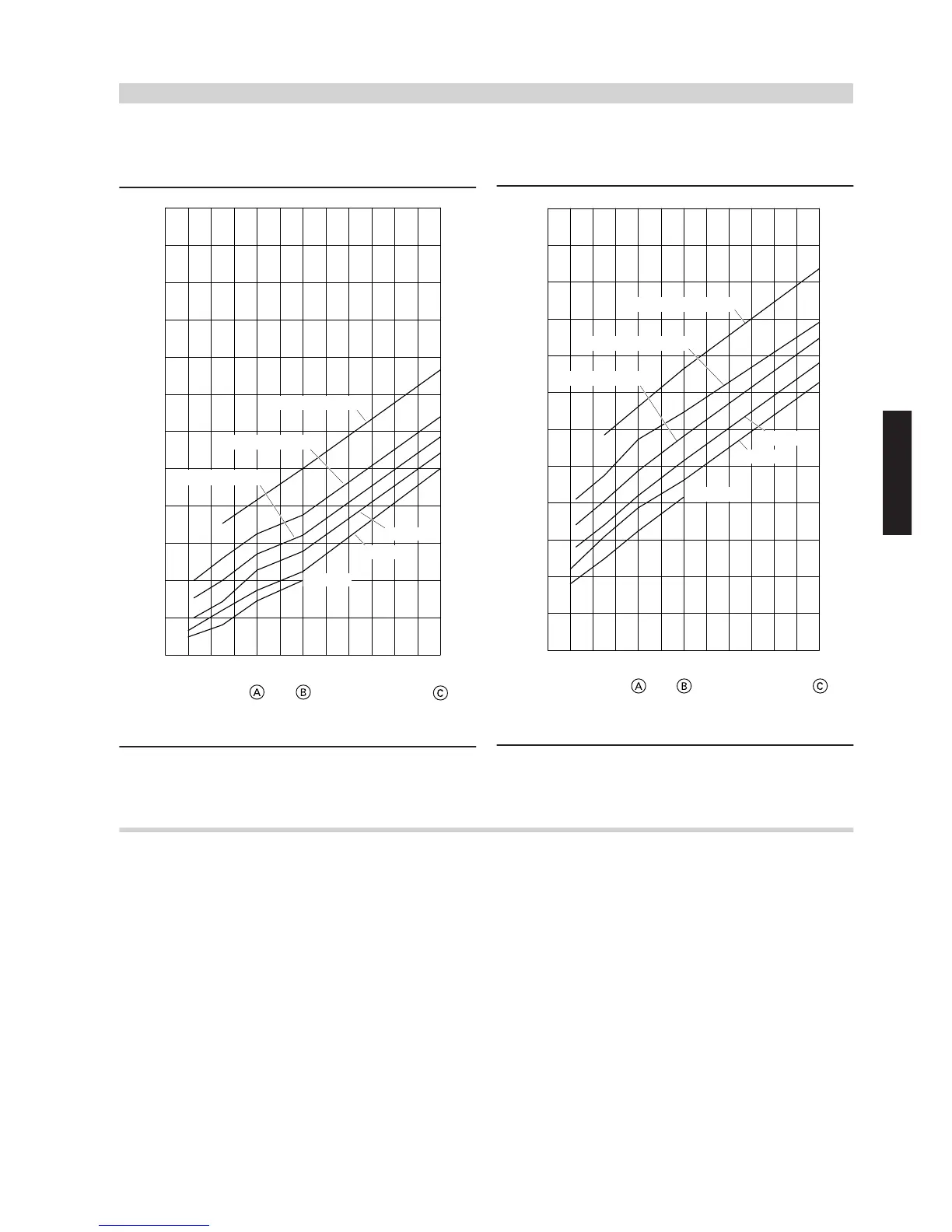

A

Vitotrans 222, 80 kW, part no. 7453 039

B

Vitotrans 222, 120 kW, part no. 7453 040

C

Vitotrans 222, 240 kW, part no. 7453 041

Peak output (during a 10 min period)

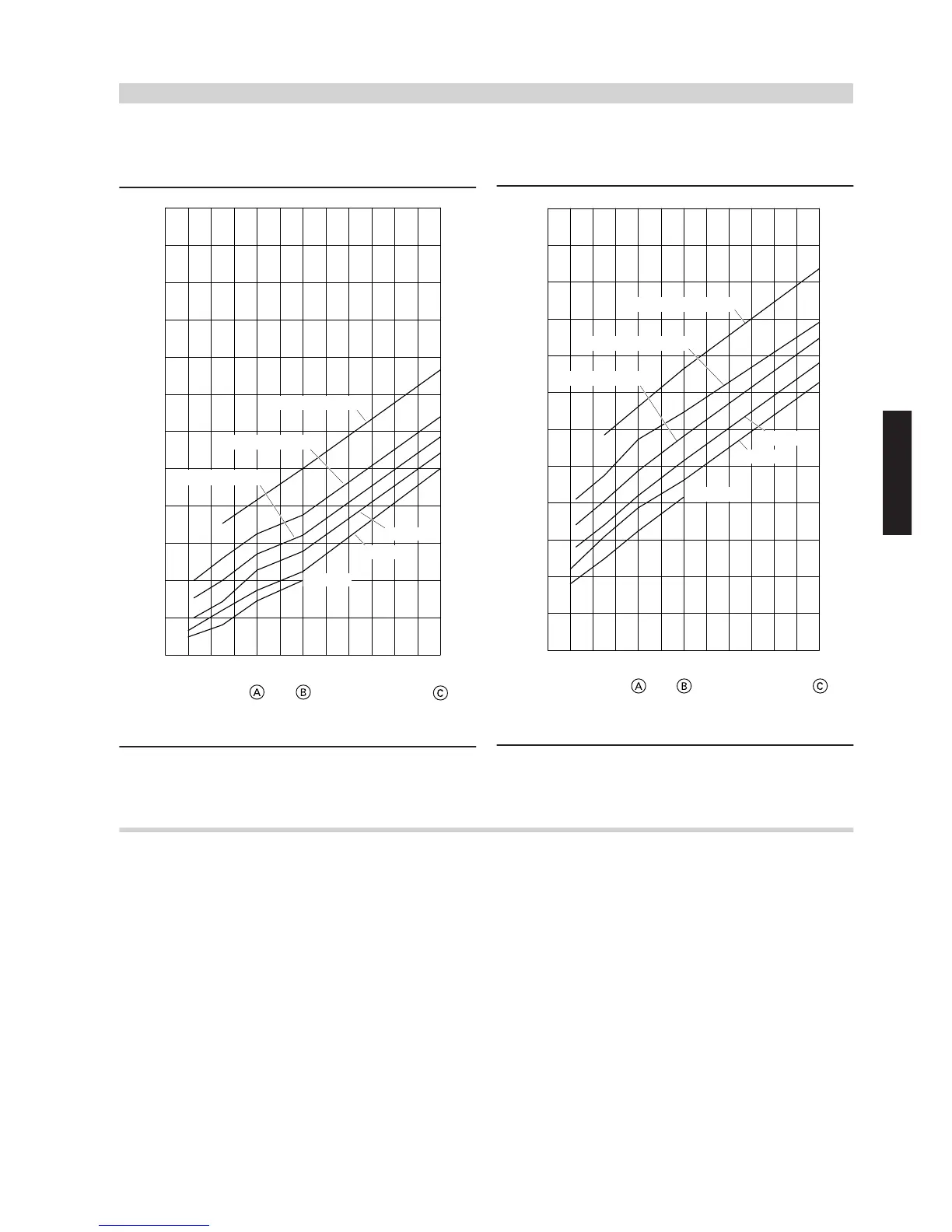

*2

A

Vitotrans 222, 80 kW, part no. 7453 039

B

Vitotrans 222, 120 kW, part no. 7453 040

C

Vitotrans 222, 240 kW, part no. 7453 041

3.2 Selection according to continuous output

In accordance with the required heating from 10 to 45 °C or from 10 to

60 °C and the planned flow temperature, the relevant column in the

following selection table is selected. The required continuous output

(see from page 22) is found in the column and the cylinder type in

the first column is read off.

Example:

DHW heating from 10 to 60 °C, flow temperature 70 °C

1

Required continuous output: 20 kW

2

, enamelled cylinder, adjacent

in the first column

3

: Vitocell 100-V 200 l or Vitocell 100-V 300 l

The most suitable DHW cylinder is now selected based on the speci-

fication and the continuous output diagrams in the Vitocell data-

sheets.

Note

The stated continuous output is only achieved when the rated boiler

heating output is greater than the continuous output.

When engineering systems with the specified or calculated continuous

output, select a matching circulation pump.

*1

The performance factor N

L

depends on the cylinder storage temperature T

cyl

.

Standard values: T

cyl

= 60 °C → 1.0 × N

L

, T

cyl

= 55 °C → 0.75 × N

L

, T

cyl

= 50 °C → 0.55 × N

L

, T

cyl

= 45 °C → 0.3 × N

L

.

*2

The peak output over 10 minutes depends on the cylinder storage temperature T

cyl

.

Standard values: T

cyl

= 60 °C → 1.0 × peak output, T

cyl

= 55 °C → 0.75 × peak output, T

cyl

= 50 °C → 0.55 × peak output,

T

cyl

= 45 °C → 0.3 × peak output.

Selecting the cylinder type

(cont.)

DHW heating

VIESMANN

11

5414 646 GB

3

Loading...

Loading...