6.5

6.5

6.5

6.513

19.5

19.5

6.5 13

A

Heating water flow

B

Heating water return

Result:

Total heating water flow rate = 19.5 m

3

/h

Heating water flow rate per cylinder = 6.5 m

3

/h

Pressure drop on the heating water side of the DHW cylinder =

400 mbar (40 kPa)

Sizing the circulation pump for cylinder heating

The circulation pump for cylinder heating must therefore deliver a

heating water flow rate of 19.5 m

3

/h and overcome the pressure drop

on the heating water side of 400 mbar (40 kPa) for the 3 cylinders, plus

the pressure drop of the boiler, the pipework between the cylinders

and the boiler, and the individual pressure drop values of fittings and

valves.

The following rule of thumb applies: If the available boiler heating out-

put

²

K

(to DIN 4701) or Φ

K

(to EN 12831) is lower than the continuous

heating output

²

Sp.

or Φ

cyl

, it is sufficient to size the circulation pump

for cylinder heating to suit the transfer of the boiler heating output. If,

on the other hand, the boiler heating output is greater than the contin-

uous output

²

cyl.

or Φ

cyl

, the circulation pump for cylinder heating can

be sized to suit the continuous output as a maximum rating.

Determining the required DHW cylinder, example 2 (with a fixed heat source temperature differential)

Preconditions:

■ Required continuous output in kW or in l/h (conversion required)

■ DHW outlet temperature in ºC

■ Cold water inlet temperature in ºC

■ Heating water flow temperature in ºC

■ Heating water return temperature in ºC

Conversion of continuous output from l/h to kW

²

req.

or Φ

req.

=

Continuous output in kW

µ

WW

= Continuous output in l/h

c = Spec. thermal capacity

ΔT

WW

= Temperature differential between DHW outlet temper-

ature and cold water inlet temperature in K

²

req.

or Φ

req.

= µ

WW

· c · ΔT

WW

The size and number of DHW cylinders required can be calculated

using the diagrams for the continuous output of the DHW cylinders

concerned.

Example:

Required continuous output = 3000 l/h

Heating water flow temperature = 80 ºC

Heating water return temperature = 60 ºC

Heating water temperature differential = 80 ºC – 60 ºC = 20 K

Cold water inlet temperature = 10 ºC

DHW outlet temperature = 45 ºC

A vertical DHW cylinder has to be used on account of the structural

characteristics of the building.

Conversion of continuous output from l/h to kW

²

req.

or Φ

req.

= µ

WW

· c · ΔT

WW

1

860

= 122 kW

= 3000 · · (45 – 10)

Calculating the continuous output of the various cylinder sizes

As the method of calculation is the same for all cylinder sizes, the

process for calculating the continuous output of the Vitocell 300-V with

300 l capacity is used here as a representative example for all cylinder

sizes (see also the datasheet for the Vitocell 300-V with 300 l

capacity).

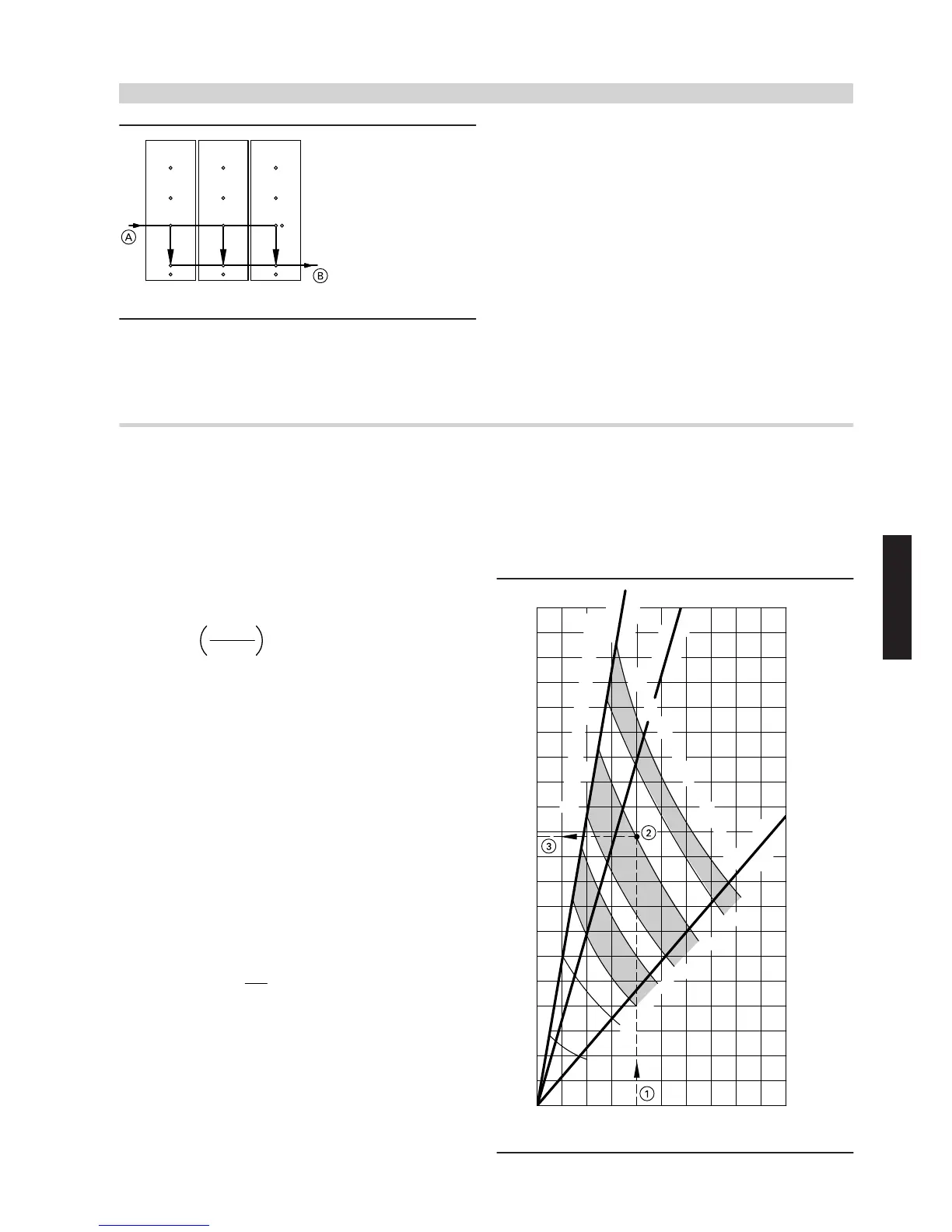

Starting from the horizontal axis at 20 K (point 1), draw a vertical line

upwards. The intersection with the curve for the required DHW heating

(from 10

1

C to 45

1

C) at the given heating water flow temperature

of 80

1

C results in point

2

.

From point

2

, draw a horizontal line.

The intersection with the vertical axis results in point

3

. You can read

off the continuous output of the DHW cylinder at point

3

as 54 kW.

DHW heating from 10 to ...°C

70

Heating water flow temperature ...°C

5.0 m³/h

280 mbar

80

50

60

90

110 mbar

3.0 m³/h

15 mbar

1.0 m³/h

500 5 40 453025201510 35

Heating water volume ... m³/h

Pressure drop on the heating water side ... mbar

Heating water temperature differential (ΔT) in K

40

45

0

5

10

15

20

25

30

35

50

55

60

65

70

75

0

80

85

90

95

100

Continuous output in kW

45

45

45

45

45

60

60

60

Sizing

(cont.)

DHW heating

VIESMANN

23

5414 646 GB

4

Loading...

Loading...