Pos. Title Number Part no.

6

In conjunction with the Vitotronic 200-H:

Immersion temperature sensor (Viessmann NTC) as cylinder temperature sensor

1 7438 702

7

Feed pump (distributor) subject to system on site

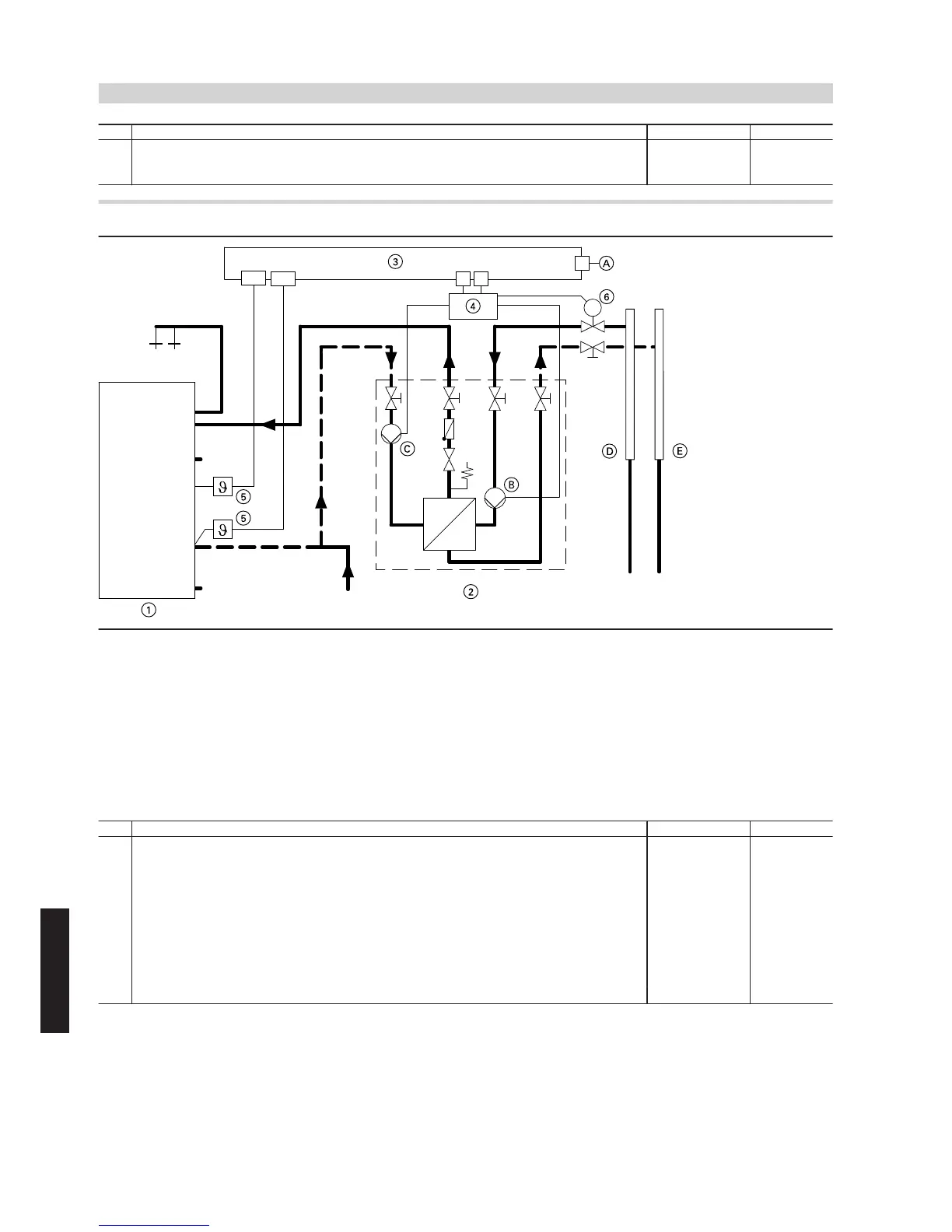

Sample application 3 – Vitocell 100-L with Vitotrans 222 and constant flow temperatures

A

Power supply connection 230 V~ 50 Hz; install a mains isolator in

accordance with regulations

B

Heating circuit pump (primary), highly efficient

C

Cylinder loading pump (secondary), highly efficient

D

Flow distributor (under pressure)

E

Return collector

Cylinder heating will be initiated by the upper temperature controller.

The lower temperature controller terminates cylinder heating.

You can select the temperature at the temperature controller.

Example:

Max. 55 ºC ON, 50 ºC OFF (at heating temperature 60 ºC).

Install a motorised valve in the flow line when connecting the Vitotrans

222 heat exchanger set for constant flow temperatures without mixer

assembly to a flow distributor (under pressure) (boiler with heating cir-

cuit pump to distributor). The motorised valve will be closed during non-

heating periods, preventing a forced flow through the Vitotrans 222

during such times.

Required components

Pos. Title Number Part no.

1

Vitocell 100-L, 500 l (shown), or subject to system Z002 074

Vitocell 100-L, 750 l, or subject to system Z004 042

Vitocell 100-L, 1000 l subject to system Z004 043

2

Vitotrans 222

– up to 80 kW 1 7453 039

– up to 120 kW 1 7453 040

– up to 240 kW 1 7453 041

3

Junction box 1 on site

4

Contactor relay

*17

1 7814 681

5

Temperature controller 2 7151 989

6

Motorised valve

*17

1 on site

*17

Only required for pressurised flow distributors.

Installation — cylinder loading system

(cont.)

48

VIESMANN

DHW heating

7

5414 646 GB

Loading...

Loading...