Calculating the heat demand for DHW heating in commercial enterprises

1. Calculating the demand

Allow for a suitable number of washing facilities (washbasins/shower

cubicles) for the type of business concerned (see the earlier

DIN 18228, sheet 3, page 4).

Per 100 users (numbers in the most numerous shift), the washing

facilities listed in table 7 are required.

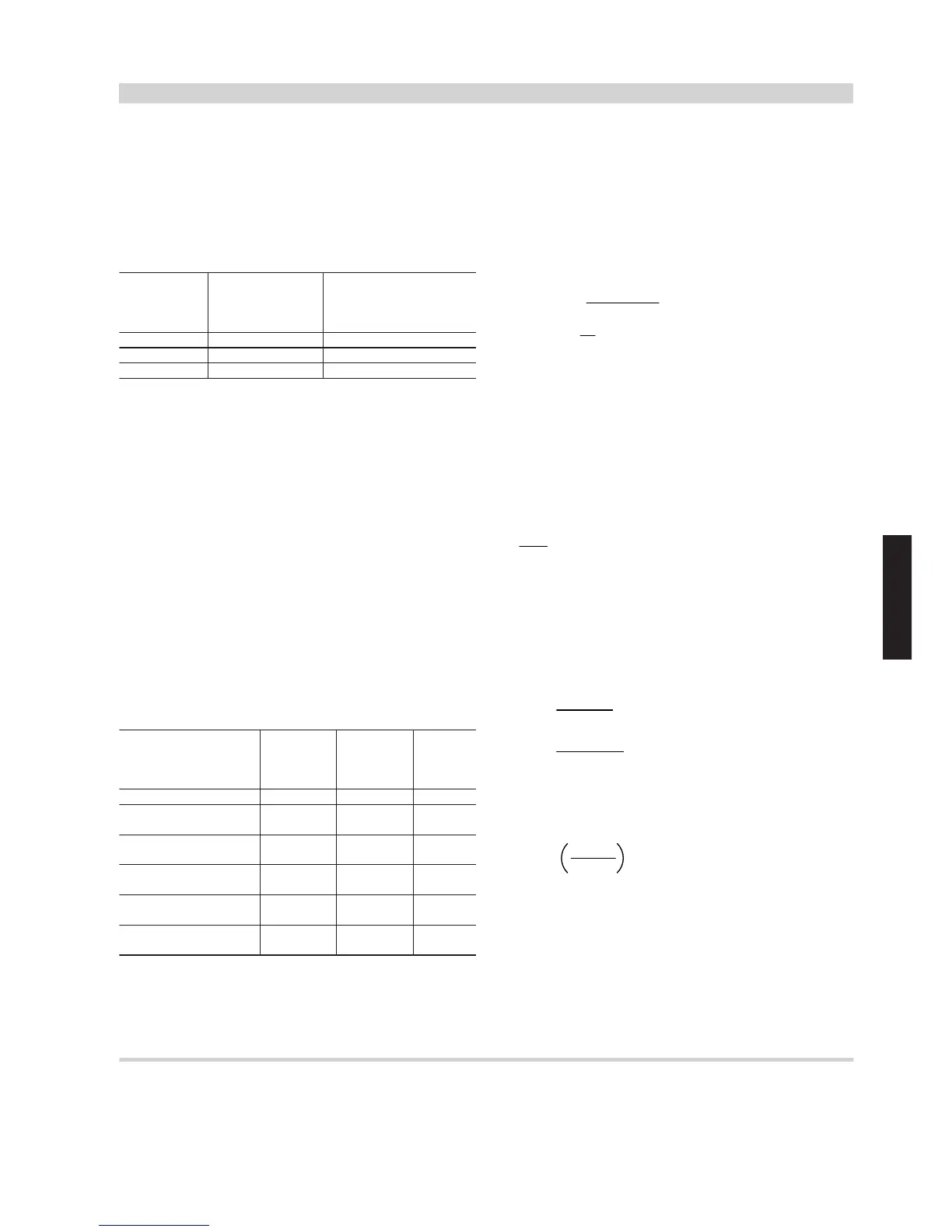

Table 7 – Standard working conditions

*11

Activity Number of wash-

ing facilities per

100 users

Splitting the washing fa-

cilities

Washing facilities/shower

cubicles

Slightly dirty 15 –/–

Moderately dirty 20 2/1

Very dirty 25 1/1

2. Sizing the DHW heating system

The following example is used to illustrate how to size the DHW heat-

ing system.

Example:

Number of employees during the most numerous

shift:

150 employees

Working pattern: 2-shift operation

Type of activity: Moderately dirty

Required DHW outlet temperature: 35 to 37 ºC

Cylinder storage temperature: 60 ºC

Cold water inlet temperature: 10 ºC

Heating water flow temperature: 90 ºC

Calculating the DHW demand

Table 7 shows that for moderately dirty work, 20 washing facilities are

required per 100 employees. The ratio of washbasins to shower cubi-

cles is 2:1.

Therefore, 20 washbasins and 10 shower cubicles are required for 150

employees.

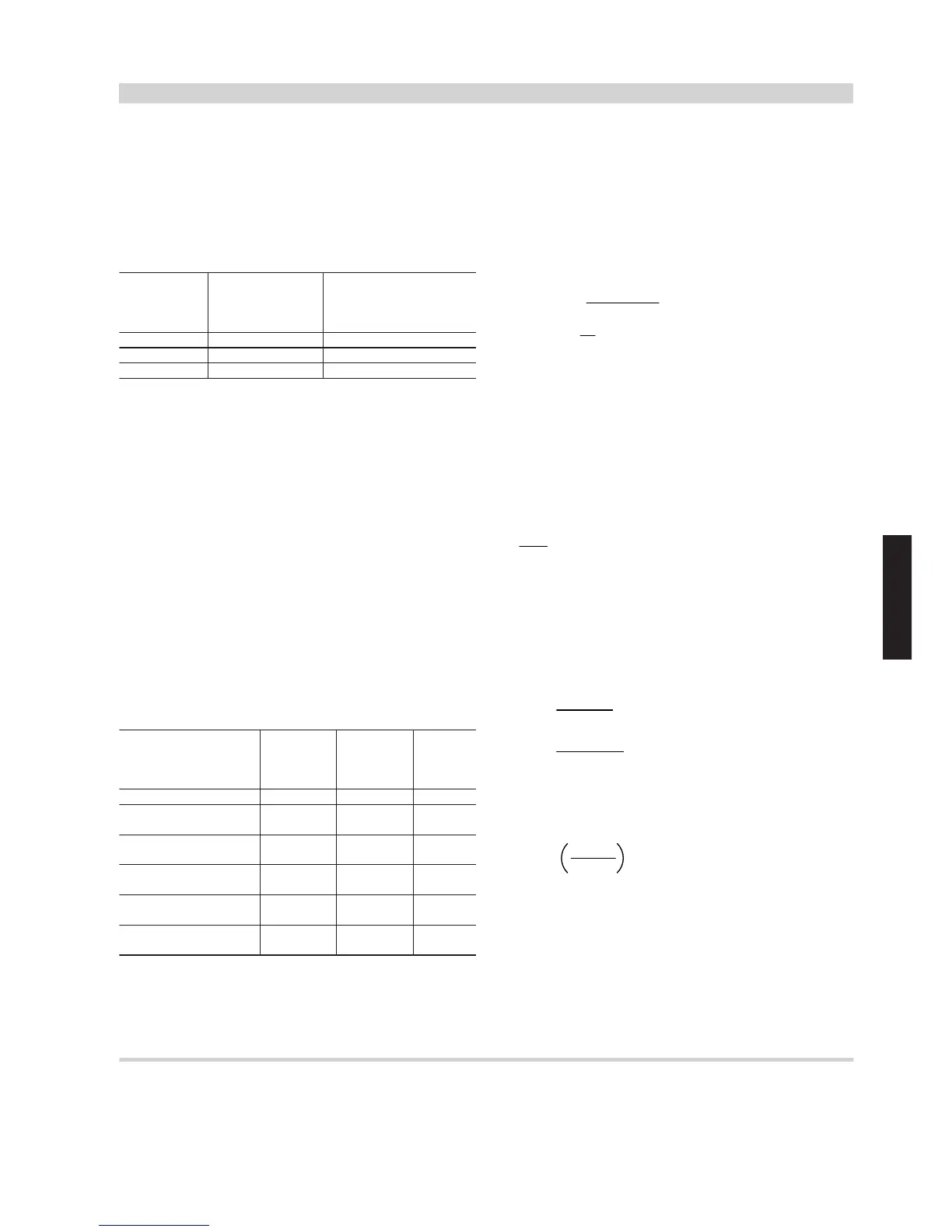

Table 8 – Consumption figures for washing facilities and shower

cubicles with a DHW outlet temperature of 35 to 37 –C

Consumption point DHW vol-

ume in l/

min

Utilisation

time in min

DHW con-

sumption

per use in

l

Washbasins with tap 5 to 12 3 to 5 30

Washbasins with spray

head

3 to 6 3 to 5 15

Circular communal wash-

basin for 6 people

approx. 20 3 to 5 75

Circular communal wash-

basin for 10 people

approx. 25 3 to 5 75

Shower cubicle without

changing cubicle

7 to 12

5 to 6

*12

50

Shower cubicle with

changing cubicle

7 to 12

10 to 15

*13

80

Assuming:

The washing facilities (washbasin with spray head) are used by 120

employees (6 times in sequence) and the shower cubicles (showers

without changing cubicles) are used by 30 employees (3 times in

sequence).

Using table 8, we arrive at the following DHW volume required:

a) DHW demand of the washing facilities: 120 × 3.5 l/min × 3.5 min =

1470 l

b) DHW demand of the showers: 30 × 10 l/min × 5 min = 1500 l

Together, a) and b) result in a total DHW demand of 2970 l at approx.

36 ºC water temperature for a utilisation period of approx. 25

minutes.

Conversion to an outlet temperature of 45 ºC, results in:

As 8 hours are available between the shifts for reheating the DHW

cylinder, the cylinder capacity should be sized for storage purposes.

For this, the details for the peak output (10-minute peak output) in the

tables in the relevant datasheets for the DHW cylinders are used.

The relevant table in the Vitocell 300-V datasheet, line "Heating water

flow temperature = 90 ºC" for the Vitocell 300-V with 500 l capacity

shows the peak output at 10/45 ºC as 627 l/10 min.

Number of DHW cylinders n = calculated total volume/selected peak

output (10 min output) of the individual cylinder

ΔT

A

= Temperature differential between the cylinder storage

temperature and the cold water inlet temperature

(60 ºC – 10 ºC) = 50 K

Z

A

= Heat-up time in h

As an empirical value, a heat-up time of approx. 2 hours is selected.

In the above example, this means that the boiler and the circulation

pump for cylinder heating (required heating water volume) should be

sized for a heat-up rating of approx. 60 kW.

Calculating the heat demand for DHW heating in hotels, guest houses and residential homes

To calculate the DHW demand, it is necessary to establish the points

of use in every room.

For this, only consider the largest point of use per single/double

room.

*11

In businesses with exceptionally dirty working conditions, 25 washing facilities are required per 100 users.

*12

Showering time excluding changing.

*13

Showering time 5 to 8 min; rest of time for changing.

Sizing

(cont.)

DHW heating

VIESMANN

17

5414 646 GB

4

Loading...

Loading...