A

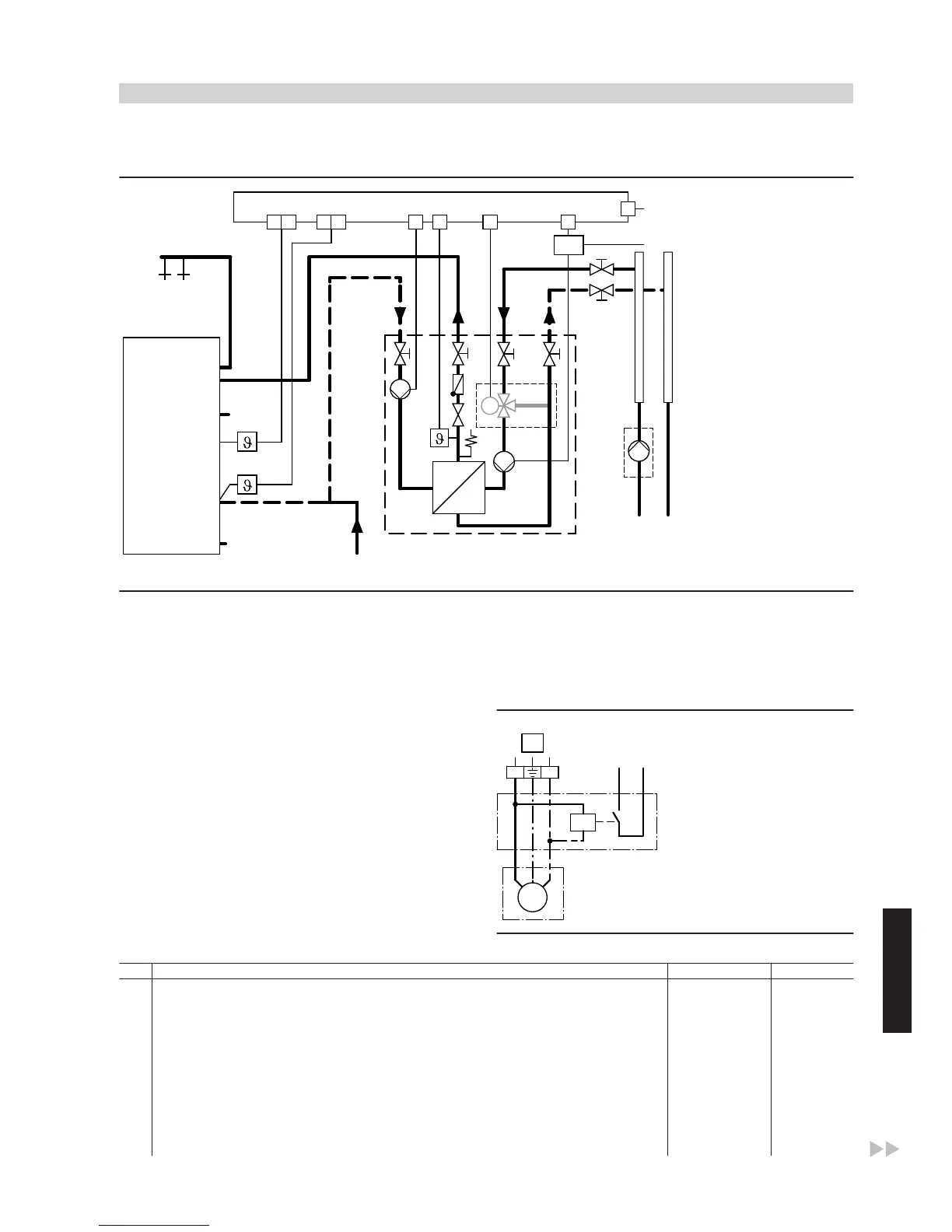

Power supply connection 230 V~ 50 Hz; install a mains isolator in

accordance with regulations

B

Flow distributor (under pressure)

C

Return collector

D

Floating contact for burner start by the third party control unit

E

Additional motorised valve in the flow to the Vitotrans 222 if the

differential pressure between the flow distributor and the return

collector > 3 bar (0.3 MPa)

In conjunction with a third party control unit, the cylinder loading pump

is regulated by the Vitotronic 200-H.

The top cylinder temperature sensor is connected to plug

%

A, while

the bottom one is connected to plug

%

B.

System-specific coding at the Vitotronic

4

Set code "4C : 1":

Use of output

sÖ

as primary pump for the heat exchanger set.

Set code "4E : 1":

Use of output

gS

as primary control for the heat exchanger set.

Set code "55 : 3":

Use of cylinder temperature control for the heat exchanger set.

Set code "6A : 113":

With Vitotrans 222, 240 kW, servomotor runtime 113 s.

Set code "9F : 1" if no outside temperature sensor is connected (e.g.

Vitotronic 200-H, type HK1B, only regulates the Vitotrans 222).

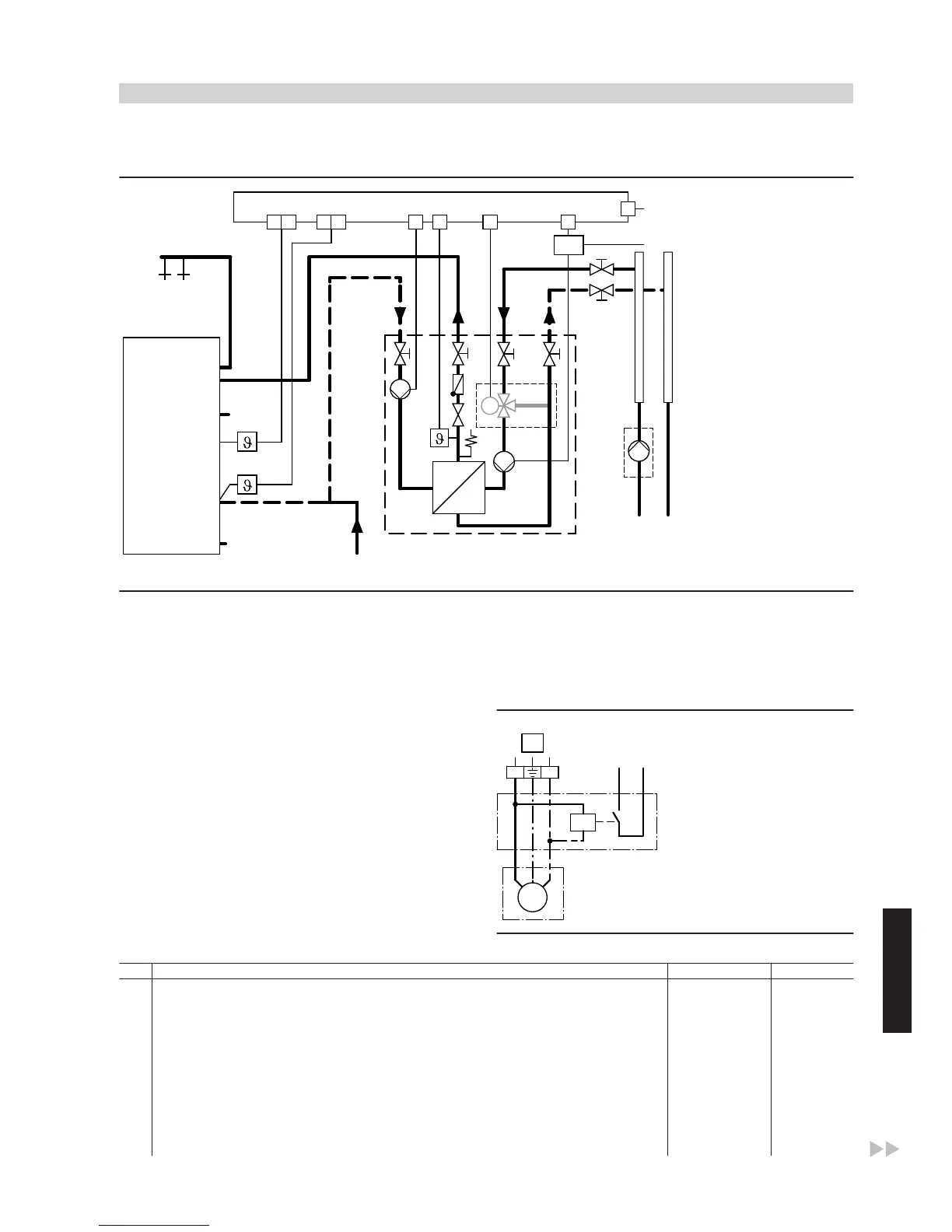

Contactor relay connection

Required components

Pos. Title Number Part no.

1

Vitocell 100-L, 500 l (shown), or subject to system Z002 074

Vitocell 100-L, 750 l, or subject to system Z004 042

Vitocell 100-L, 1000 l subject to system Z004 043

2

Vitotrans 222

– up to 80 kW 1 7453 039

– up to 120 kW 1 7453 040

– up to 240 kW 1 7453 041

3

Mixer assembly (incl. 3-way mixing valve, servomotor, sensors, pipework) for the Vitotrans 222

– up to 120 kW 1 7164 620

– up to 240 kW 1 7164 621

4

Vitotronic 200-H 1 see pricelist

5

Contactor relay 1 7814 681

Installation — cylinder loading system

(cont.)

DHW heating

VIESMANN

47

5414 646 GB

7

Loading...

Loading...