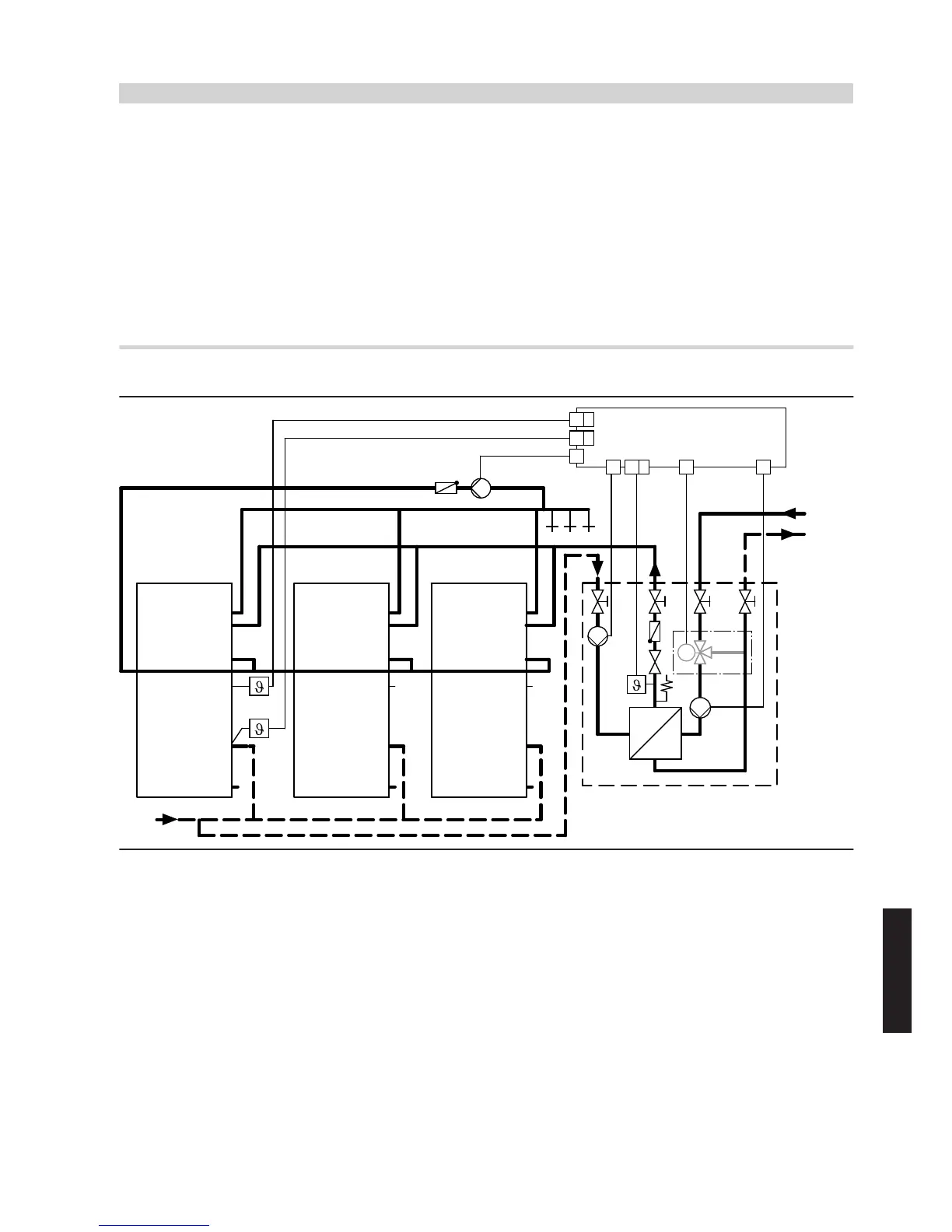

F

Heating water flow

G

Heating water return

H

Common cold water connection with safety assembly to

DIN 1988

K

Vitocell 100-L (here: 500 l capacity)

L

Cylinder loading pump (secondary), highly efficient

N

Spring-loaded check valve

O

Cylinder temperature sensor, top

(ON, plug

%

A)

P

Cylinder temperature sensor, bottom

(OFF, plug

%

B)

Note

■

Establish cold water connection H with a tee with straight flow to

the cold water connection of the Vitocell-L. Always make the cold

water connection to the Vitotrans 222 as a tee branch.

■ In larger DHW circulation networks, it may be necessary to briefly

switch off the DHW circulation pump to enable heating of the Vitocell

100-L.

Due to the necessary high flow temperatures of the heat source, never

use a directly connected heating circuit without mixer.

For optimum operation, disable the DHW cylinder priority control at the

control unit.

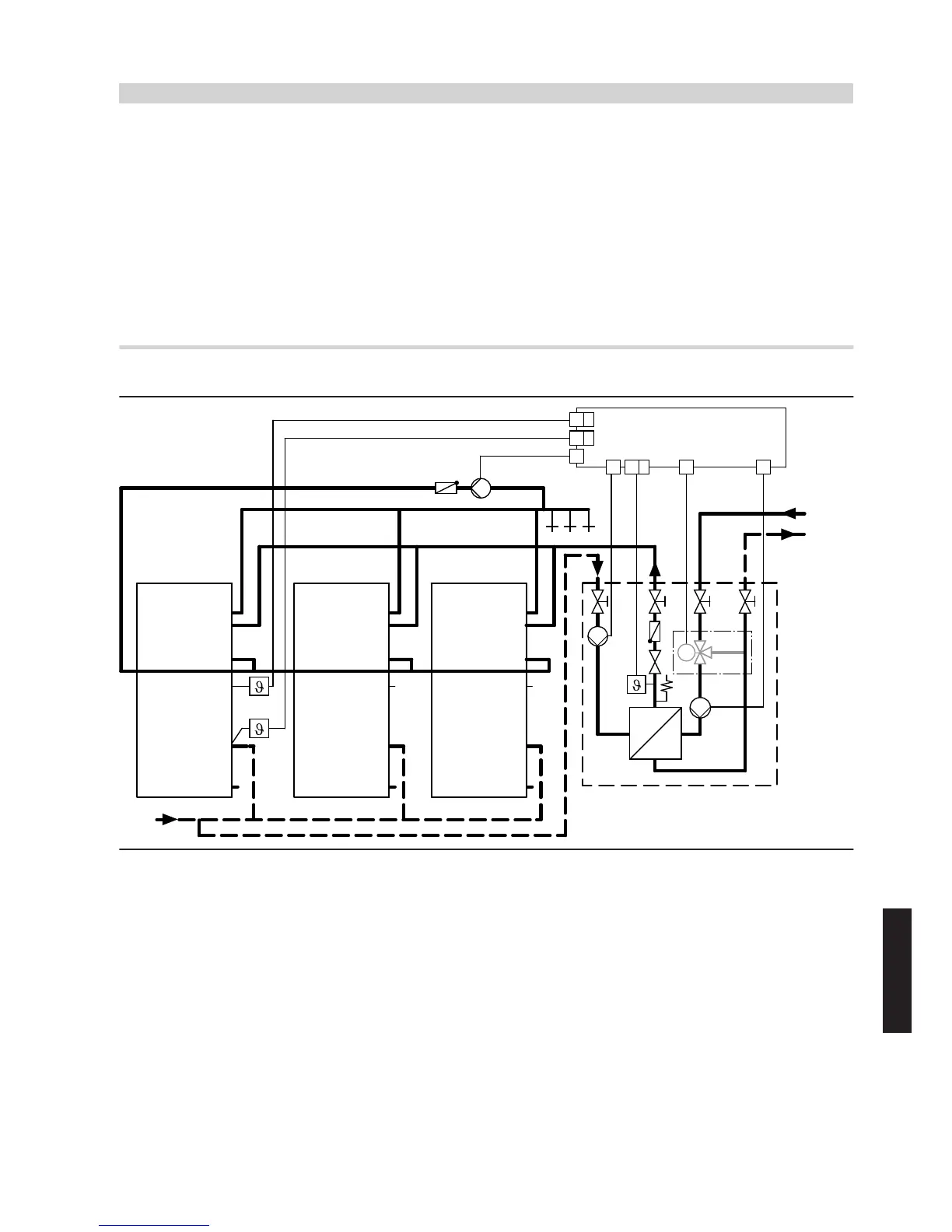

Version 2 — cylinder loading system with several Vitocell 100-L in parallel and Vitotrans 222 for modulating

flow temperatures

A

Vitocell 100-L (here: 500 l capacity)

B

DHW circulation pipe

C

DHW circulation pump

D

Draw-off points (DHW)

E

Vitotrans 222 heat exchanger set with mixer assembly

F

Vitotronic 200-H (type HK1B, type HK3B),

Vitotronic 100 (type GC1B, GC4B),

Vitotronic 200 (type GW1B),

Vitotronic 300 (type GW2B, type GW4B) or

Vitotronic 300-K (type MW1B, type MW2B)

G

Plate heat exchanger

H

Heating water flow

K

Heating water return

L

Cylinder loading pump (secondary), highly efficient

N

Common cold water connection with safety assembly to

DIN 1988

O

Spring-loaded check valve

P

Cylinder temperature sensor, top

(ON, terminals

%

A)

Q

Cylinder temperature sensor, bottom

(OFF, terminals

%

B)

Note

Establish cold water connection

N

with a tee with straight flow to the

cold water connection of the Vitocell-L. Always make the cold water

connection to the Vitotrans 222 as a tee branch.

Parallel operation is particularly suitable for systems where the domi-

nant design criterion is a high peak output, e.g. for sports halls, sports

grounds, swimming pools or shower rooms in commercial enterpri-

ses.

Parallel operation makes it possible to extract the max. draw-off rate

from each DHW cylinder. The DHW cylinders can be reheated in a

short time after the hot water has been drawn off subject to a suffi-

ciently high heat exchanger output being available.

Due to the necessary high flow temperatures of the heat source, never

use a directly connected heating circuit without mixer.

For optimum operation, disable the DHW cylinder priority control at the

control unit.

Installation — cylinder loading system

(cont.)

DHW heating

VIESMANN

41

5414 646 GB

7

Loading...

Loading...