© 2011 Viking Preferred Service

25

Service Diagnostics and Procedures

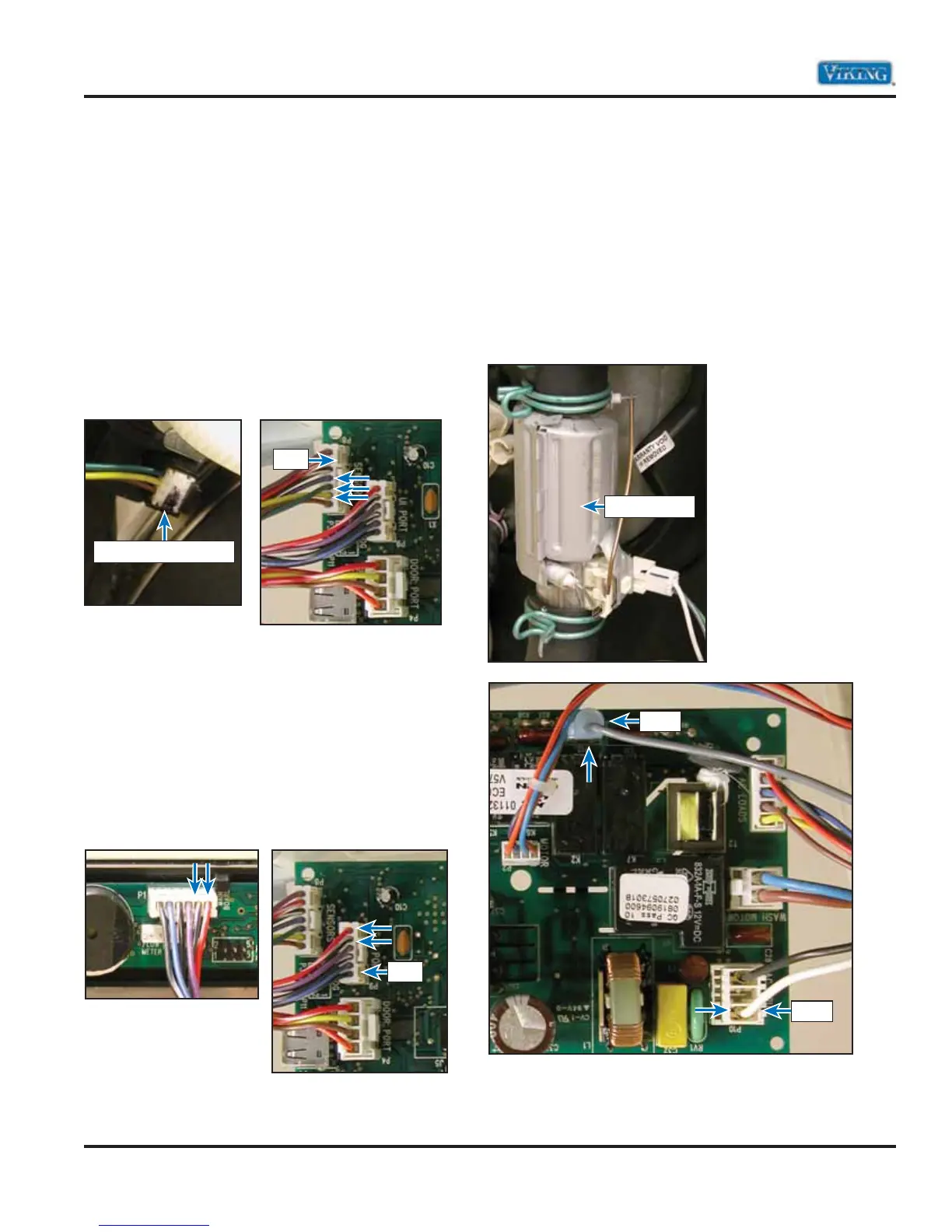

Washer Pressure Sensor

The sensor is mounted to the sump retainer ring.

As the water level increases, the pressure in the 1

pressure tube, connected to the level sensor input,

increases as well. This pressure causes an internal

amplifier to vary the output voltage to the board.

Forexample, an empty sump should produce a

reading of .5 -.8 Volts DC between P8-6 (yellow)

and P8-5 (ground) while a full sump should read

approximately 3.5 volts DC. Depending on the

water level, the output voltage to the Control Board

changes and is processed in the board.

User Interface Port

The user interface allows the end consumer to make

cycle selections. As the selection is made, the signal

is sent to the control board via a ribbon connection.

Voltage between P9-1 and P9-2 should be 12 VDC.

If no voltage is found, check ribbon connector. If

connector is OK, replacement of the user interface

is necessary (see Control Panel Removal procedure,

page 30).

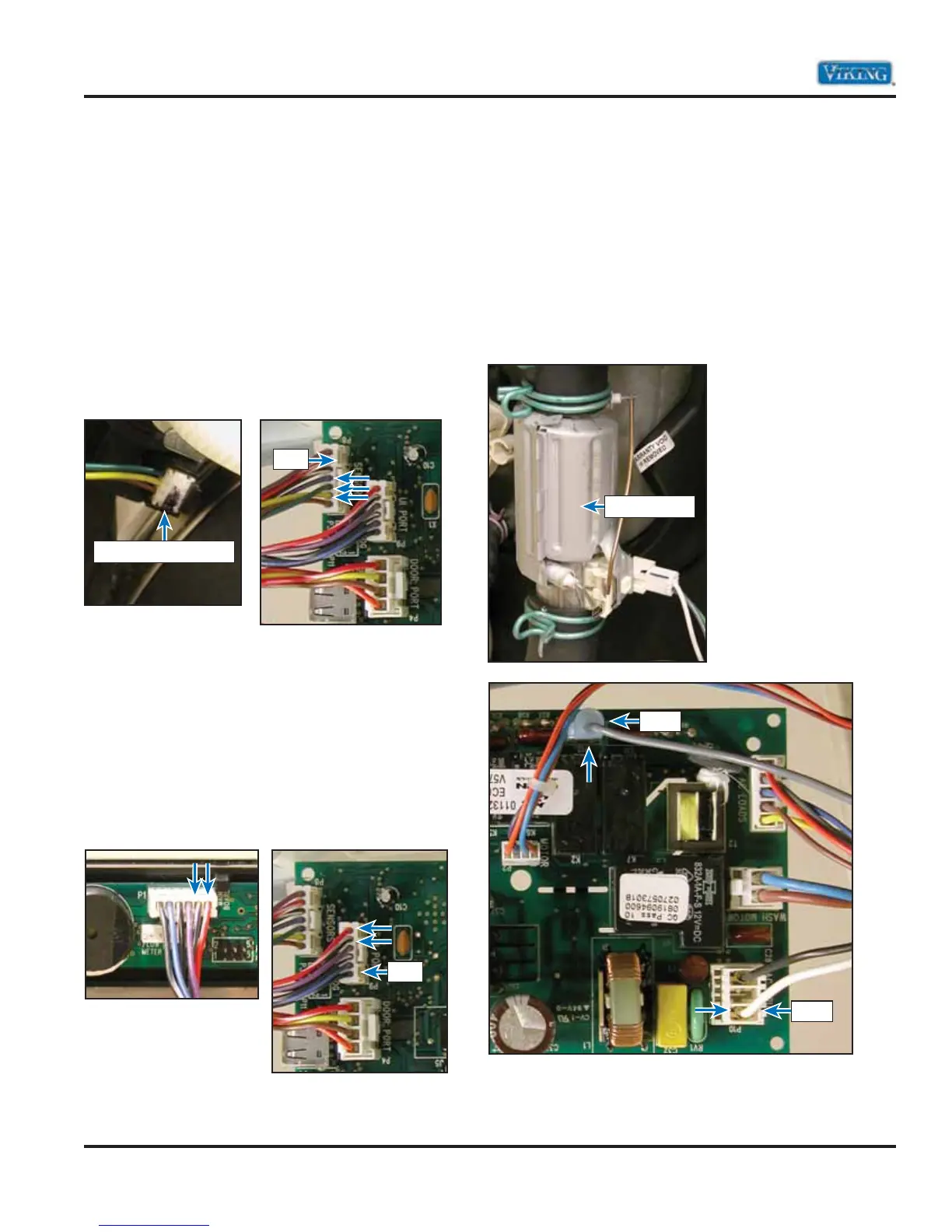

Water Heater

The unit uses a 120-volt, 1200 watt heater to heat

the water during the wash cycle. To check the

heater, unplug the gray wire on P12 and using an

ohmmeter, check for 12 ї ohms between the gray

wire and Neutral. If 0 їohms are read, check the

wiring to the heater. If the wiring is correct, replace

the heater. The heater can also be tested in the

Diagnostic mode (see pages 14-15).

Control Board Diagnosis (continued)

(

Some measurements require power and others require the unit not to be powered.)

Water Pressure Sensor

P-8

Main Control Board

P-9

Main Control Board

User Interface Board

P-10

P-12

Water Heater

Main Control Board

Loading...

Loading...