Technical Reference Manual-XPM3m Revision Date: August 2014

TROUBLESHOOTING:

The quadrature encoder used on the rail width adjust is not subjected to much mechanical stress because of the

slow rotating speed of the rail adjust lead screw and also due to the intermittent operation of the rail width adjust

hardware. A properly aligned quadrature encoder shouldn’t wear out or need to be replaced.

If an auto rail position fails to count or update verify the following:

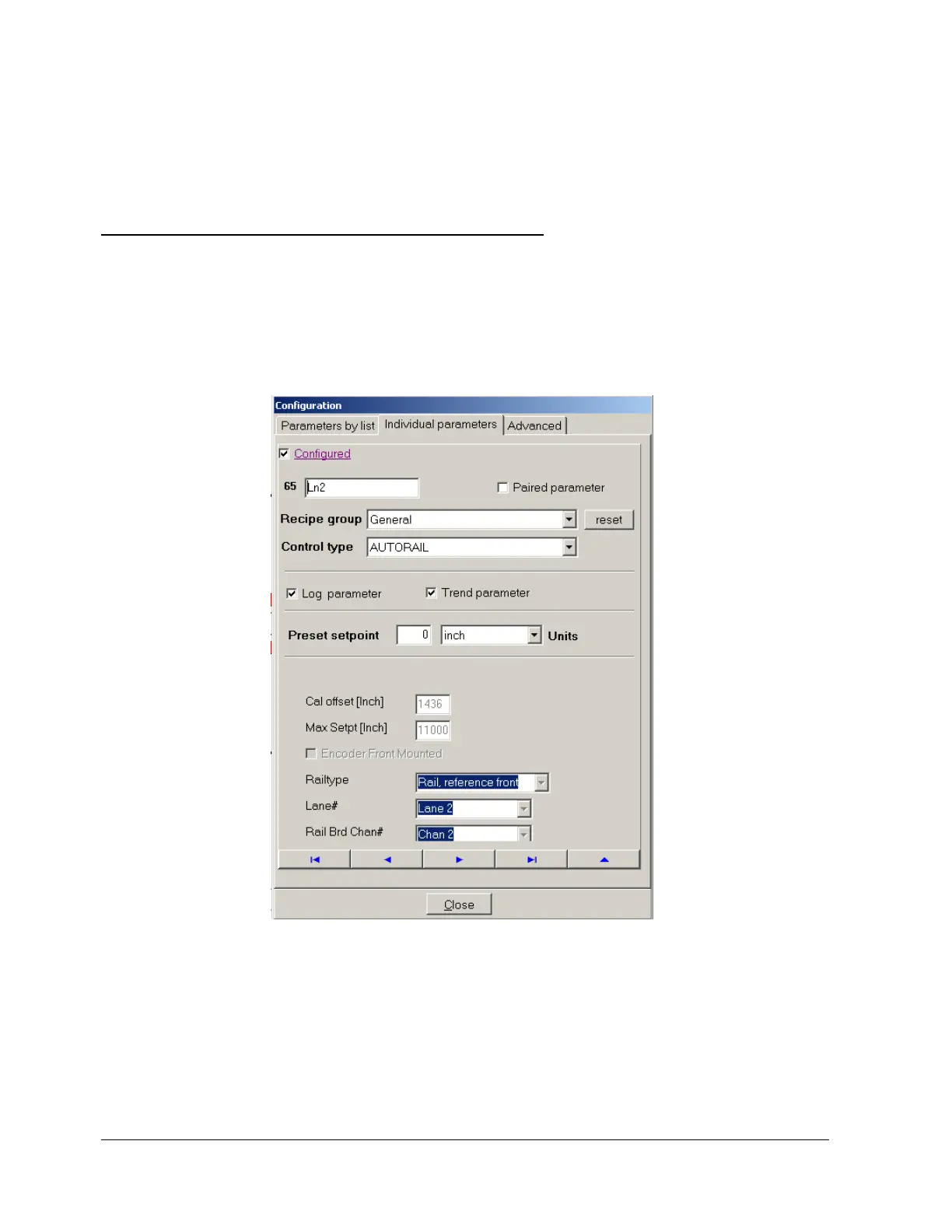

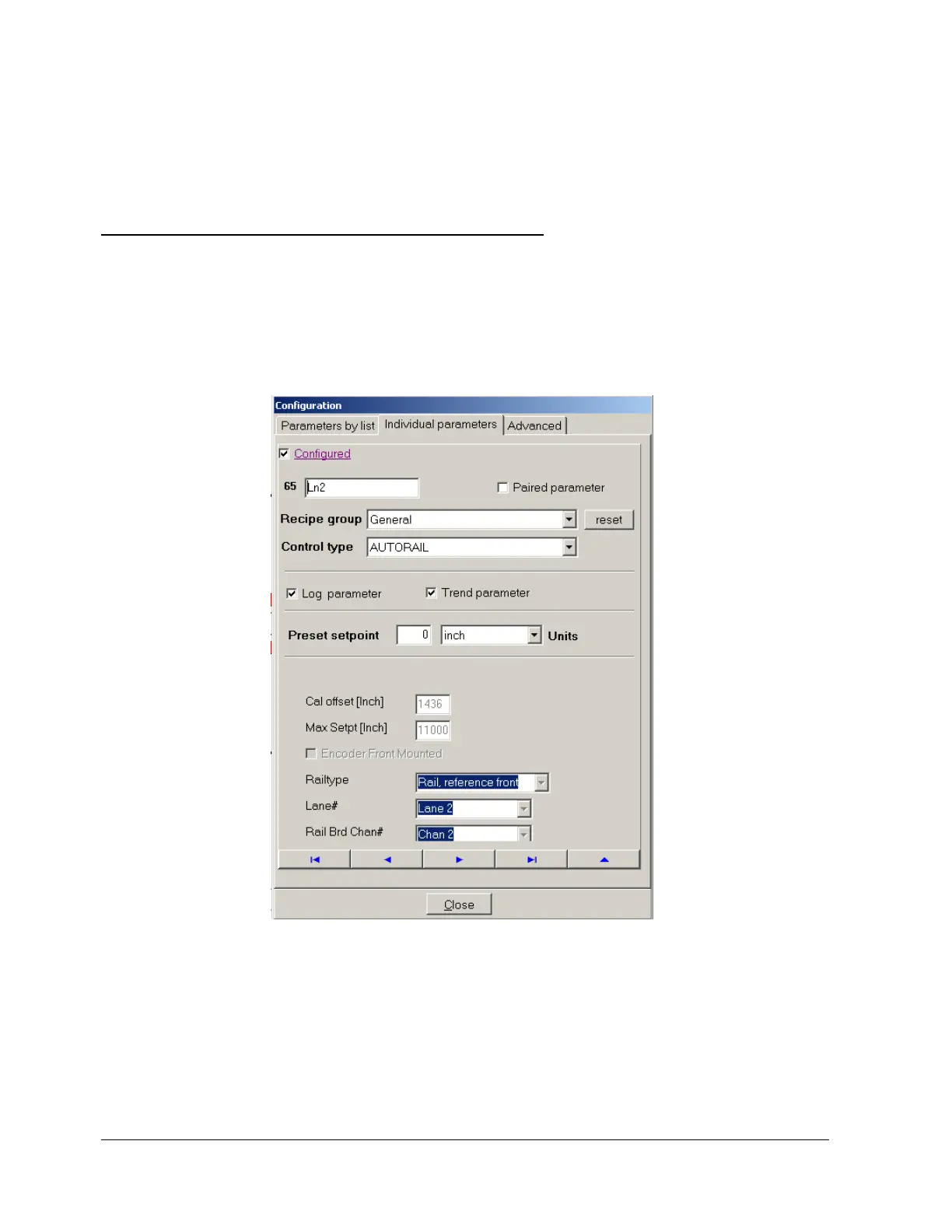

1. The PC oven software is configured correctly. The correct lane number, and axis type is specified for an axis.

The valid choices for lane number are 1 or 2. The axis type determines how and what direction the oven

controller moves and axis. The valid selection choices for axis type are moveable rail reference front, moveable

rail reference rear, board support 1 or board support 2. To view this configuration will require the highest level

of password. The configuration can be viewed under the Vitronics Soltec menu. Go to Configuration,

Parameters, Individual Parameters. Click on the button with the blue arrow pointing to the right until you come

to the parameter you wish to view.

An axis will always reference at its fixed rail location by moving towards the fixed rail until the in limit switch input

is encountered and then moving away from the fixed rail in the opposite direction until the in limit switch input is

present again. Each quadrature counter is cleared or reset to zero when a rail axis is set to its in limit switch and

then moved away from the in limit switch until the in limit switch signal is present again. This is considered the

true reference position for an axis. Because the make contact distance for a limit switch can vary due to the

large amount of over travel built into the switch mechanism, but the break contact distance is relatively constant

and therefore more accurate to use as a reference.

Loading...

Loading...