Operating manual High-pressure double diaphragm pumps Cobra 40-10; Cobra 40-25

5 Description

22 Order number 2340851 | Edition 05/2022

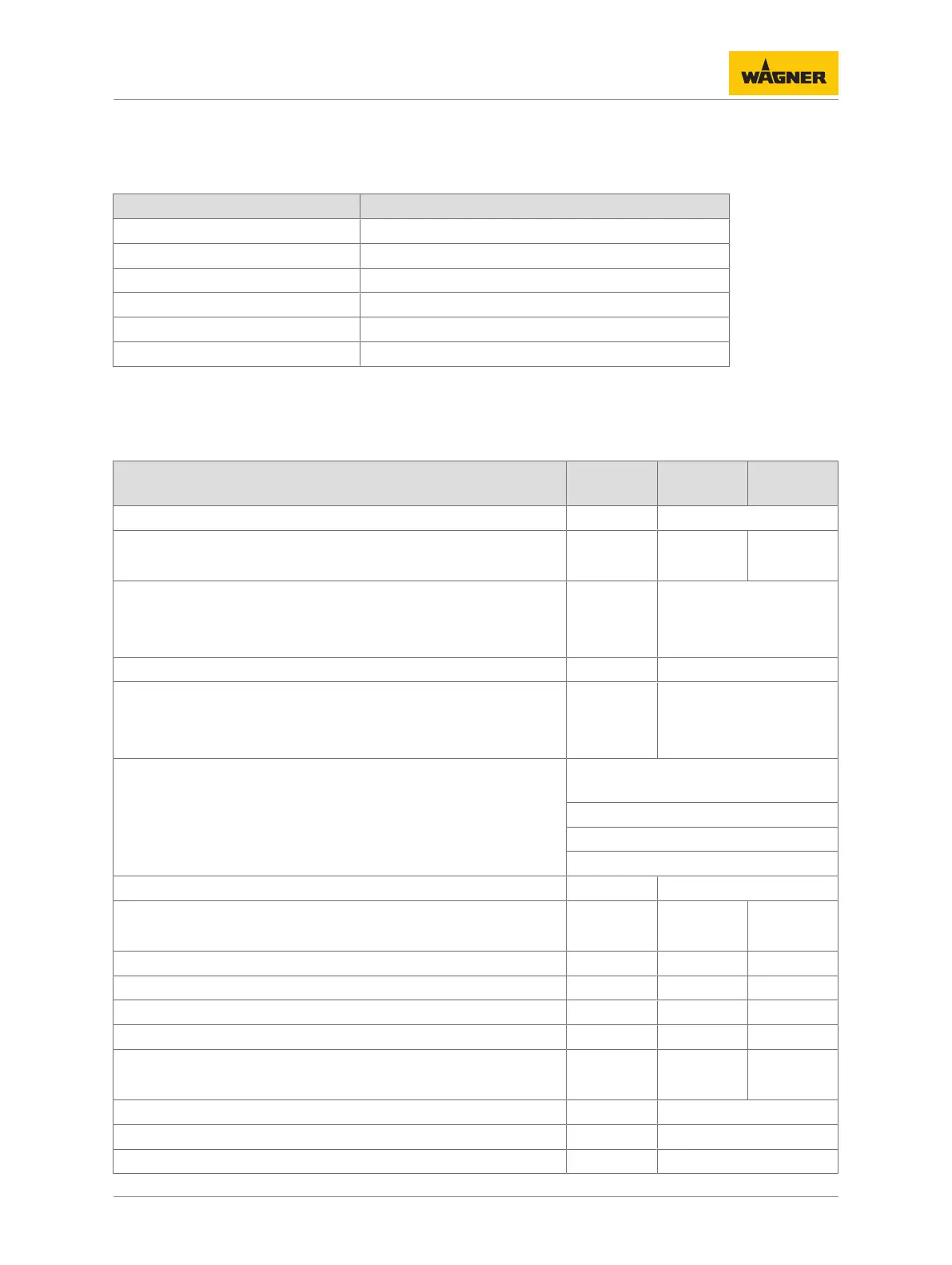

5.5 DATA

5.5.1 Materials of the Parts Transporting Paint

Paint-wetted part Material

Inlet housing Consital (aluminum alloy)

Fluid Section Consital (aluminum alloy)

Valves balls Stainless steel

Valve seats/valve cone Carbide

Diaphragms PA-resistant

Valve fitting 1.4104

PA = polyamide

Positions of the individual parts: see Chapter Spare Parts [865].

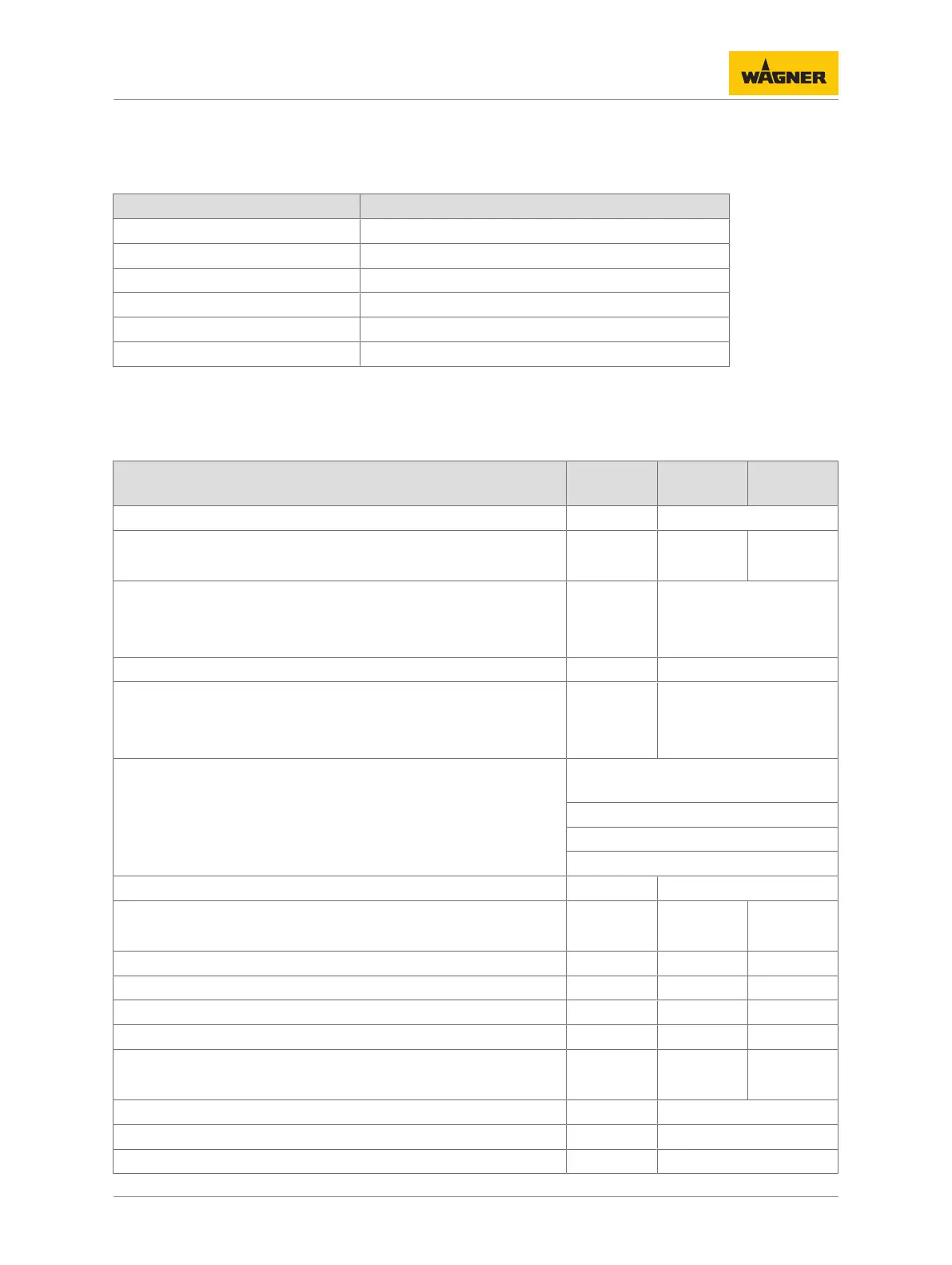

5.5.2 Technical Data

Description Units Cobra

40-10

Cobra

40-25

Pump ratio 40:1

Flow volume per double stroke (DH) cm³ / cc

cu inch

10

0.6

25

1.5

Maximum operating pressure MPa

bar

psi

25

250

3626

Maximum possible strokes in operation DH/min 200

Minimum/maximum air inlet pressure MPa

bar

psi

0.25 – 0.6

2.5 – 6

36.3 – 87

Compressed air quality: free from oil and water Quality standard 7.5.4 according to ISO

8573.1, 2010

7: Particle concentration 5–10mg/m³

5: Humidity: pressure dew point ≤ 7 °C

4: Oil content ≤5mg/m³

Ø air inlet (inside thread) inch G 1/2"

Minimum Ø of the compressed air supply line mm

inch

13

0.51

19

0.75

Air consumption at 0.6 MPa; 6 bar; 87 psi per double stroke NL 3.5 8.3

Sound pressure level at maximum permissible air pressure* dB(A) 74 76

Sound pressure level at 0.45 MPa; 4.5 bar; 65.27 psi air pressure* dB(A) 72 74

Sound pressure level at 0.3 MPa; 3 bar; 43.5 psi air pressure* dB(A) 69 71

Air motor piston diameter mm

inch

80

3.15

100

4

Product input (outside thread) mm M36×2

Product output (inside thread) inch G 3/8"

Product output (outside thread) inch G 3/8"

Loading...

Loading...