60

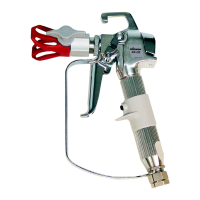

GM 5000EA

OPERATING MANUAL

EDITION 04/2016 ORDER NUMBER DOC2344499

Functional fault Cause Remedy

Insu cient product output Nozzle too small Select larger nozzle (see Accessories).

Product pressure too low Increase product pressure.

Product pressure generator blocked Clean or replace lter.

Nozzle is clogged Clean or replace nozzle.

Product valve travel set too small Increase product valve travel by turning

the adjusting screw.

Poor spray pattern Wrongly adjusted atomizing air Readjust the atomizing air.

Unfavorable nozzle size Select a di erent nozzle (see

Accessories).

Product pressure too high/too low Adapt product pressure.

Spray product viscosity too high Thin product in accordance with the

manufacturer's instructions.

Damaged nozzle Attach new nozzle.

Poor wrap-around Poor grounding at object Check grounding of object or hanger

with ohmmeter.

Lacquer resistance too high/too low Check lacquer resistance, see

Chapter2.5

Spraying pressure too high Readjust spraying pressure.

No wrap-around No high voltage Switch on high voltage at the control

unit. / Repair malfunction as explained

in the control unit operating manuals.

Connect gun and gun cable/check for

defect.

Check lacquer resistance, see

Chapter2.5

Seal in end piece defective Repair by WAGNER Service Department.

Air-passages damp Clean and dry air passages.

Back-spray Poor grounding at object Check grounding.

Distance between spray gun and

object too large

Reduce distance between spray gun

and work piece.

High voltage set wrongly (too high) Adapt high voltage to product.

Loosen the nozzle union nut for

round jet method

Slightly tighten union nut by hand.

Valve rod leaks Seals at the valve rod are damaged Replace the seals (see Chapter 10).

Loose packing Tighten.

9 TROUBLE SHOOTING AND RECTIFICATION

Loading...

Loading...