74

GM 5000EA

B_03260

OPERATING MANUAL

EDITION 04/2016 ORDER NUMBER DOC2344499

11.2 AIR TEST

11.3 PRODUCT PRESSURE TEST

Connect test or air hose to spray gun.

The following air tests are to be carried out twice each:

- at 0.1MPa; 1bar; 14.5psi

- at 0.8MPa; 8bar; 116psi

Checking the air valve

The air valve must switch on and o correctly.

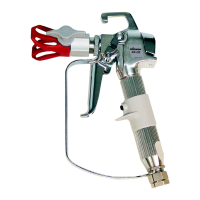

Air seal

Without activating the trigger, test for air seal at the points

marked in the illustration.

Connect low-pressure hose to the spray gun.

Spray gun with suitable medium (e.g., ushing agent or Marcol 52) and a maximum

pressure of 0.8 MPa; 8 bar; 116 psi. Increase the pressure gradually while doing so.

Observe the following gun components:

Product connection, nozzle body, product valve (no post-spraying).

Exploding gas / air mixture!

Danger to life from ying parts and burns.

Never spray into a closed tank.

Ground the tank.

DANGER

11.4 TEST OF SPRAY PATTERN

Check spray pattern in accordance with Chapter 7.3.2.

Loading...

Loading...