2-16 Preparing for operation

Setting up analog signals

You can set up output analog signals to record system information.

Requirement: Analog signals require a Waters eSAT/IN Module in the

system.

See also: Waters e-SAT/IN Module Installation Guide.

To enter analog information:

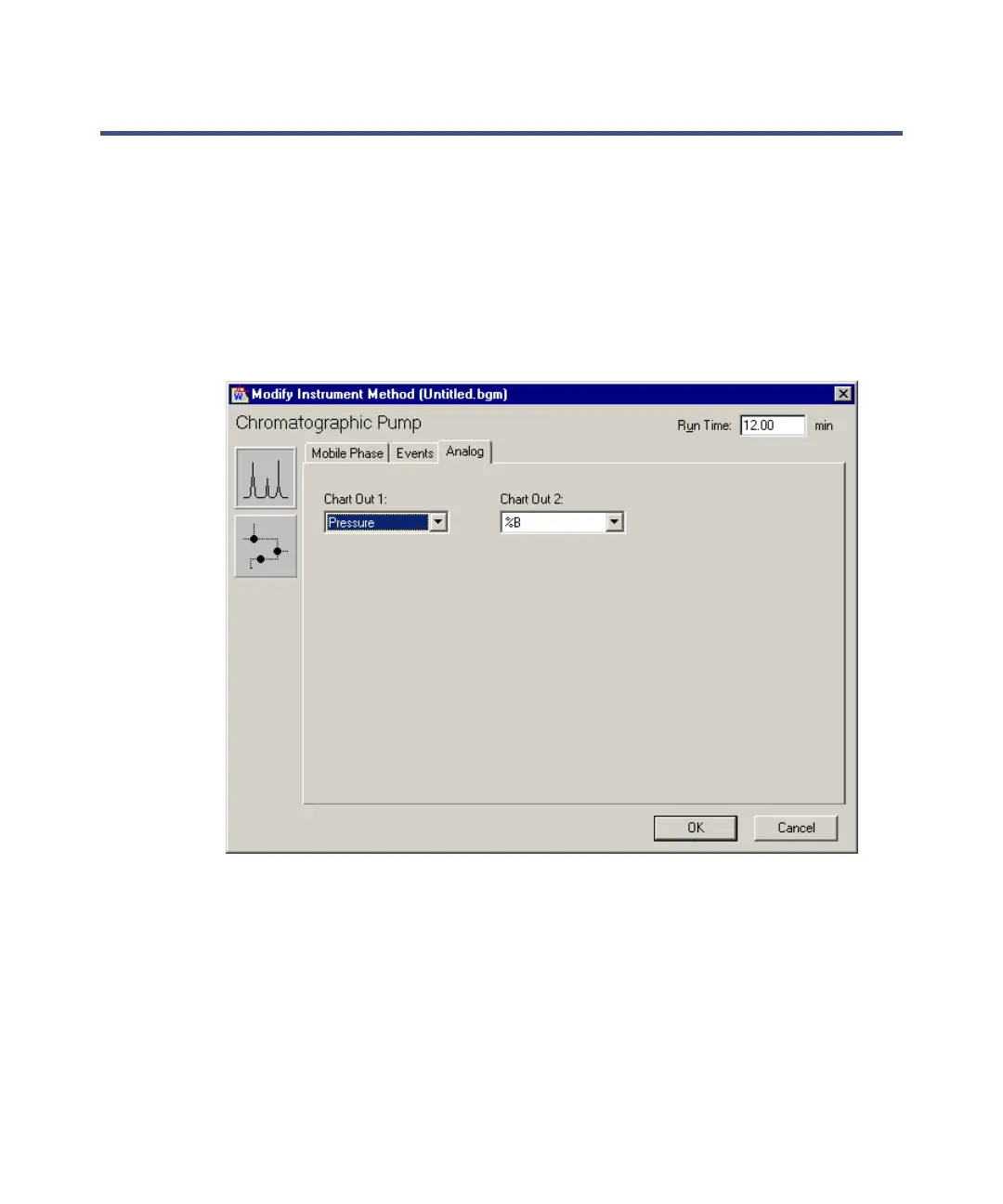

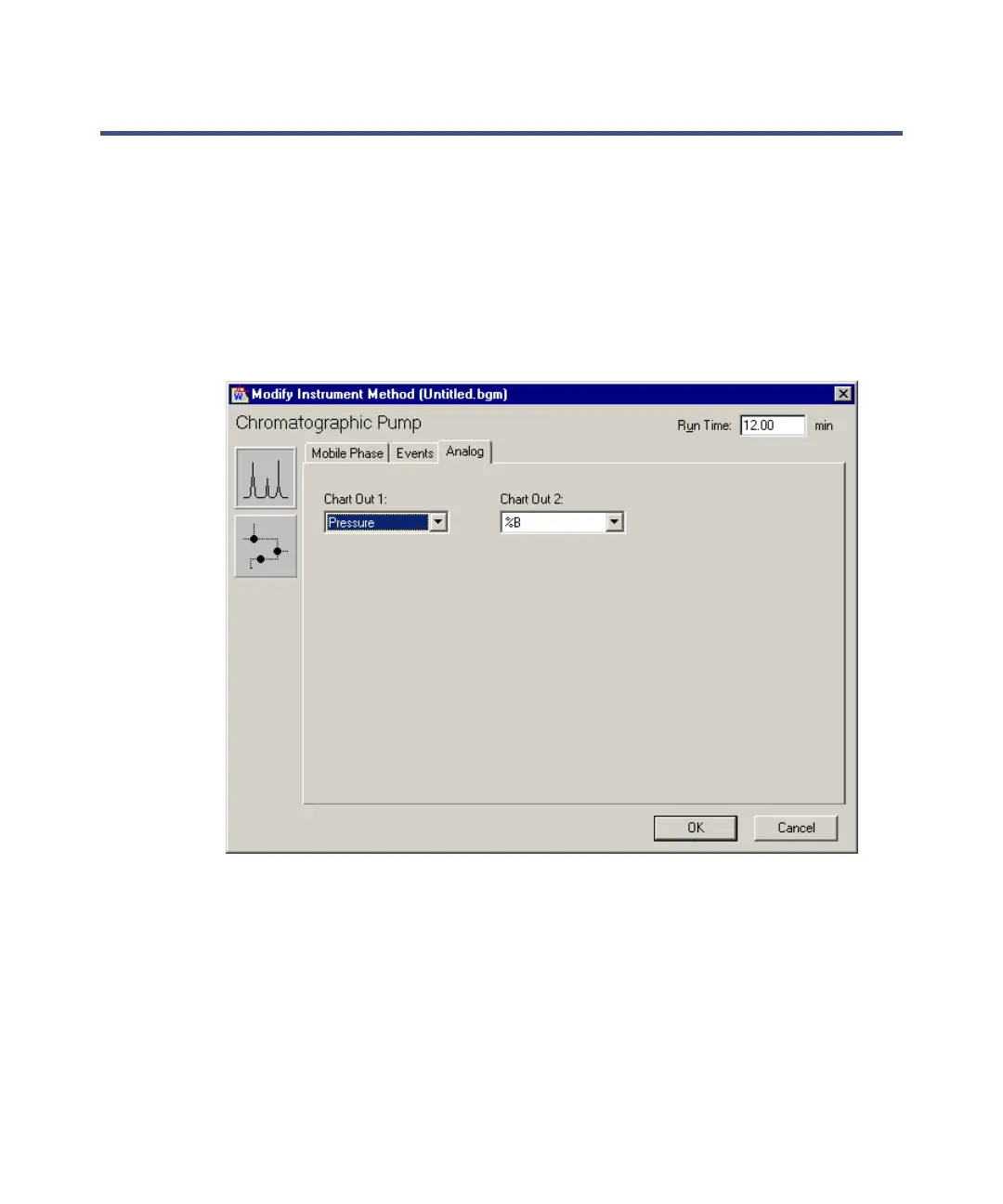

1. In the Modify Instrument Method screen, click the Analog tab.

2. Select the optional analog signals from the Chart Out 1 and Chart Out 2

drop-down lists, and then click OK. Valid signals are %A, %B, Pressure,

or Flow Rate.

Tip: The full scale output voltage is 2.0.

Loading...

Loading...