Solvent management system specifications B-7

Solvent management system specifications

Solvent management system specifications

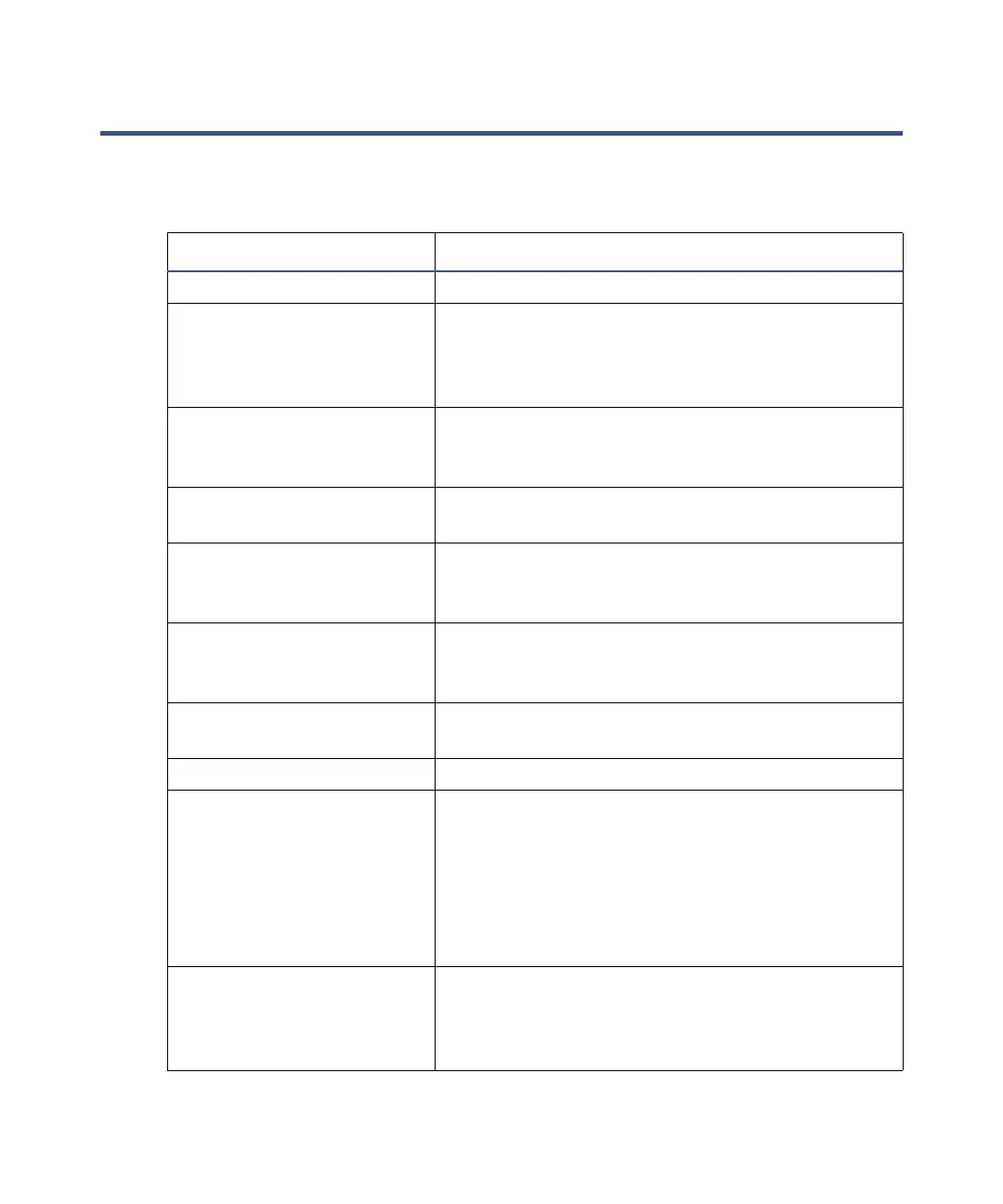

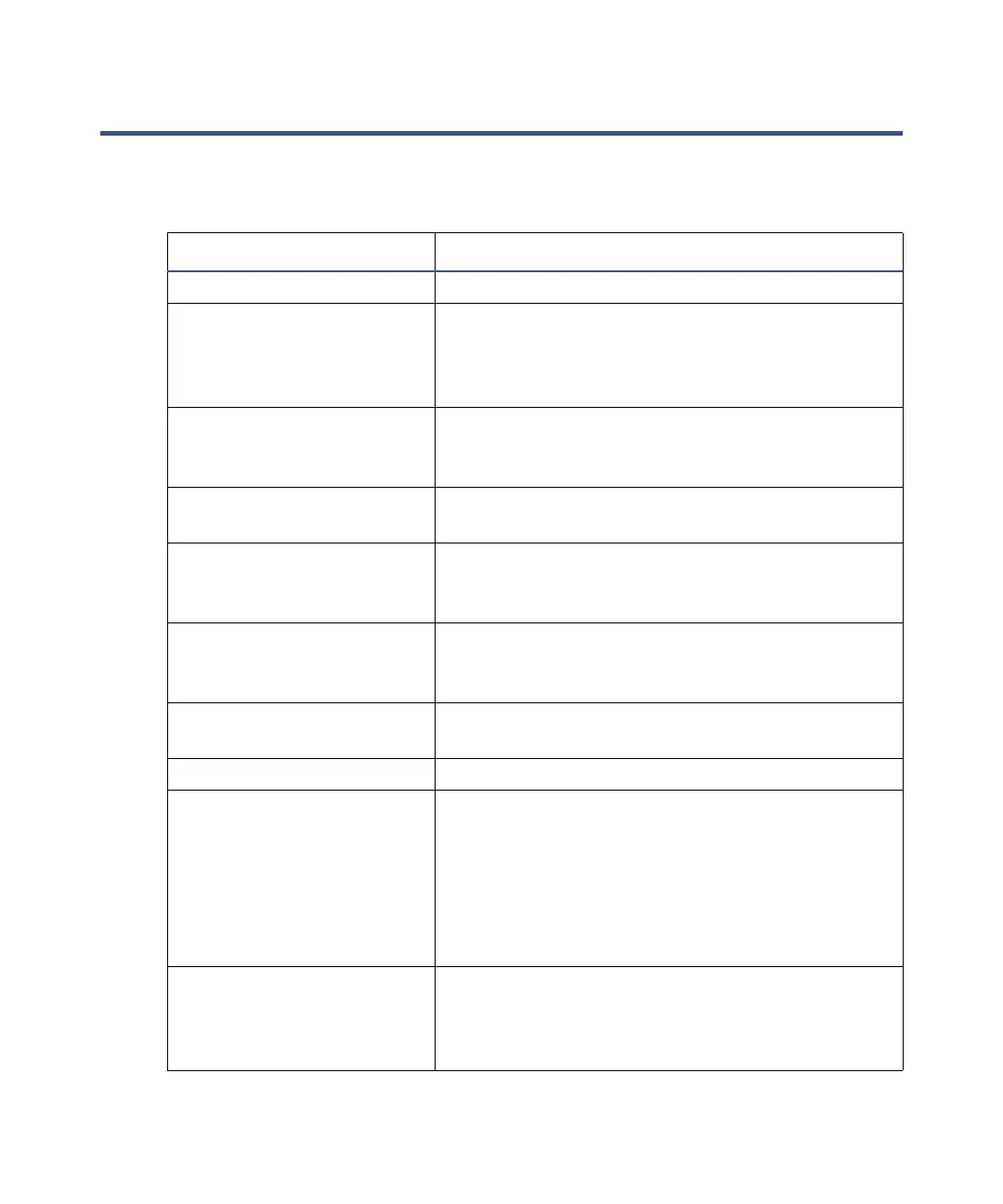

Item Specification

General High pressure mixing, binary gradient.

Priming Ability to self-prime from a solvent container on

the floor with wet pump heads and dry tubes

(no intervention from the operator such as a

syringe).

Number of solvents Up to four (4): A1, A2, B1, and B2. User must

choose A1 or A2 and B1 or B2 before the start of

the gradient.

Solvent and seal-wash

containers

User-selectable.

Primary wetted materials 316 stainless steel, UHMWPE, Sapphire, Ruby,

Tefzel (ETFE), Teflon (FEP, PTFE, PFA),

Nitronic 60, Valcon H, Chemraz, and PEEK™.

Pump seal-wash (for two

seal-wash pumps)

Pump and seals required to wash the rear of the

high-pressure seal (pulsed type flow, about

20 µL per pulse).

Flow rate, pressure

operating envelope

See page B-9.

Flow rate increment 0.01 mL/min.

Delay volume Delay volume of the binary gradient module is

effectively zero because the two pumps are

connected together at the outlet filter/tee.

System delay volume depends on the tubes

and/or mixers and fittings between the outlet of

the binary gradient module and the column

inlet.

Flow accuracy ±1.0% of required flow or 10 mL/min, whichever

is greater. Flow rate 1.00 to 150.00 mL/min,

using water or MeOH, back pressure

approximately 4140 kPa (41 bar, 600 psi).

Loading...

Loading...