June 28, 2016, 715003956 Rev. C

Page 83

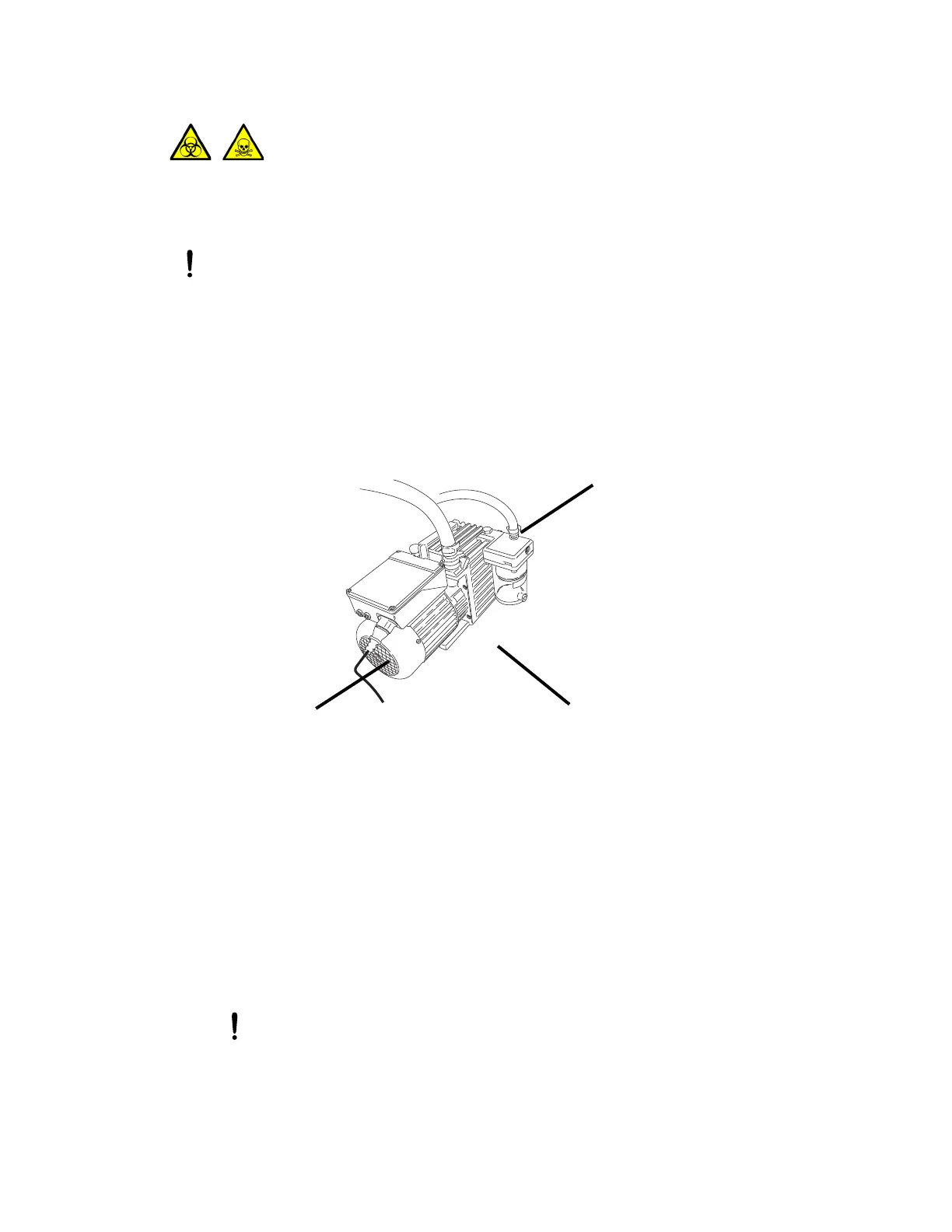

Figure D–3: Backing pump clearance

To connect the backing pump:

1. Place a suitable PTFE drip tray on the floor, within 5 feet of the instrument.

Requirement: The pump must be oriented in a way that allows easy daily access to the gas

ballast valve and oil-level sight glass.

2. Place the pump on the PTFE drip tray.

3. Using the NW16 center ring and clamp, and the 7-mm nut driver, attach the flanged end of a

length of 1-inch ID vacuum hose to the vacuum port on the pump.

4. Using a hose clamp, connect the opposite end of the length of 1-inch vacuum hose in step 3

to the 1-inch OD straight vacuum port on the instrument’s rear panel.

5. Using a hose clamp, connect a length of 19-mm clear PVC exhaust tubing to the pump

exhaust port.

Warning: The pump and its connections can be contaminated with biohazardous and/or toxic

materials. Always wear chemical-resistant, powder-free gloves when performing this procedure.

Notice:

• To ensure the correct operation of the backing pump, it must be installed within 1

degree of horizontal.

• The area where the backing pump is located must have an ambient temperature of 15

to 40 ºC (59 to 104 ºF).

• To ensure proper ventilation, the pump must be installed with the following minimum

clearances:

Notice: To avoid gas leaks, use the sharp knife to cut the PVC exhaust tubing

squarely (that is, perpendicular to its horizontal axis).

Right-side minimum clearance is

15.24 cm (6 inches)

Back-side minimum clearance is

15.24 cm (6 inches)

Front-side minimum clearance is

35.56 cm (14 inches)

Left-side minimum clearance is

15.24 cm (6 inches)

Loading...

Loading...