3-38 Troubleshooting, Testing, and Maintenance

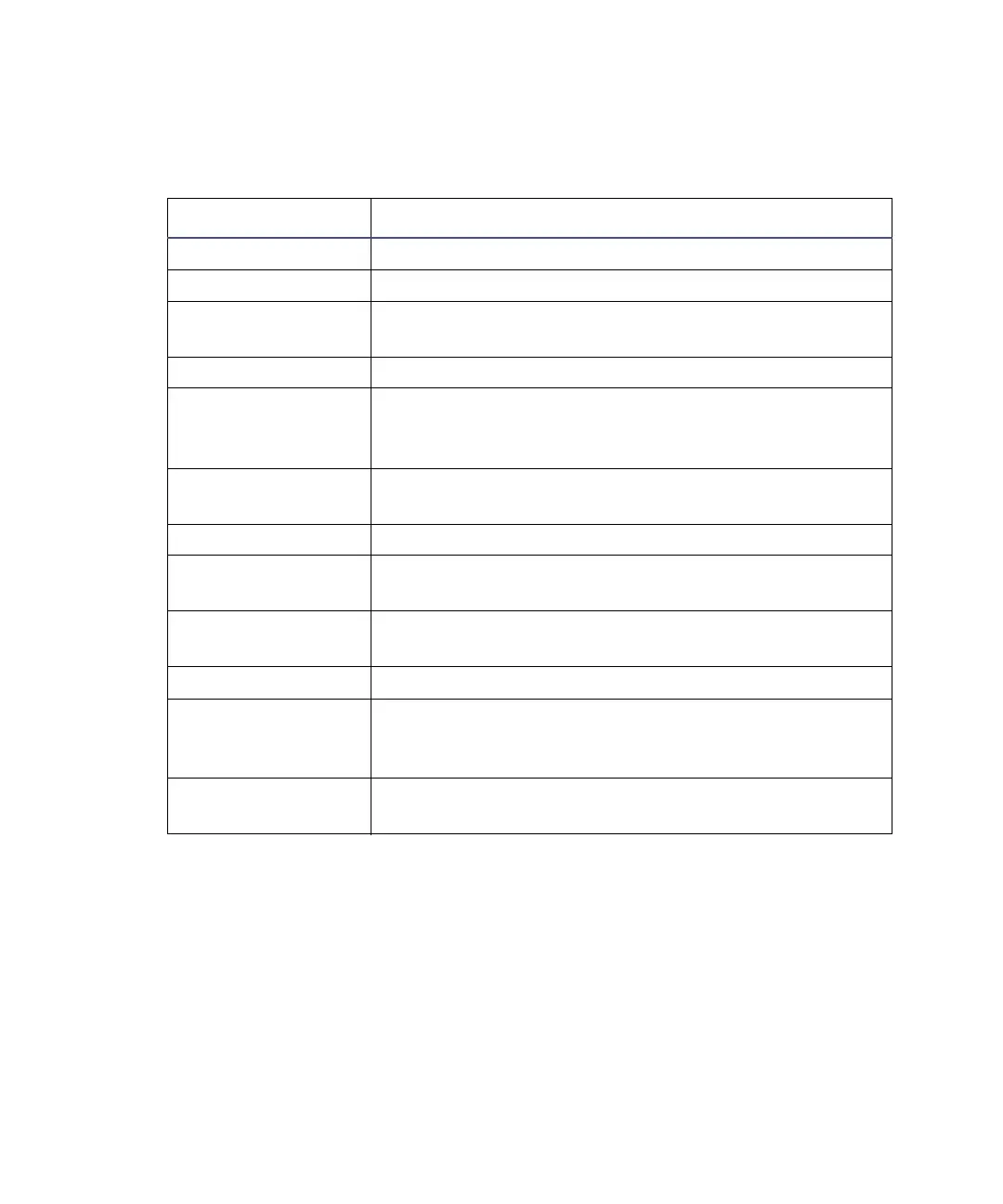

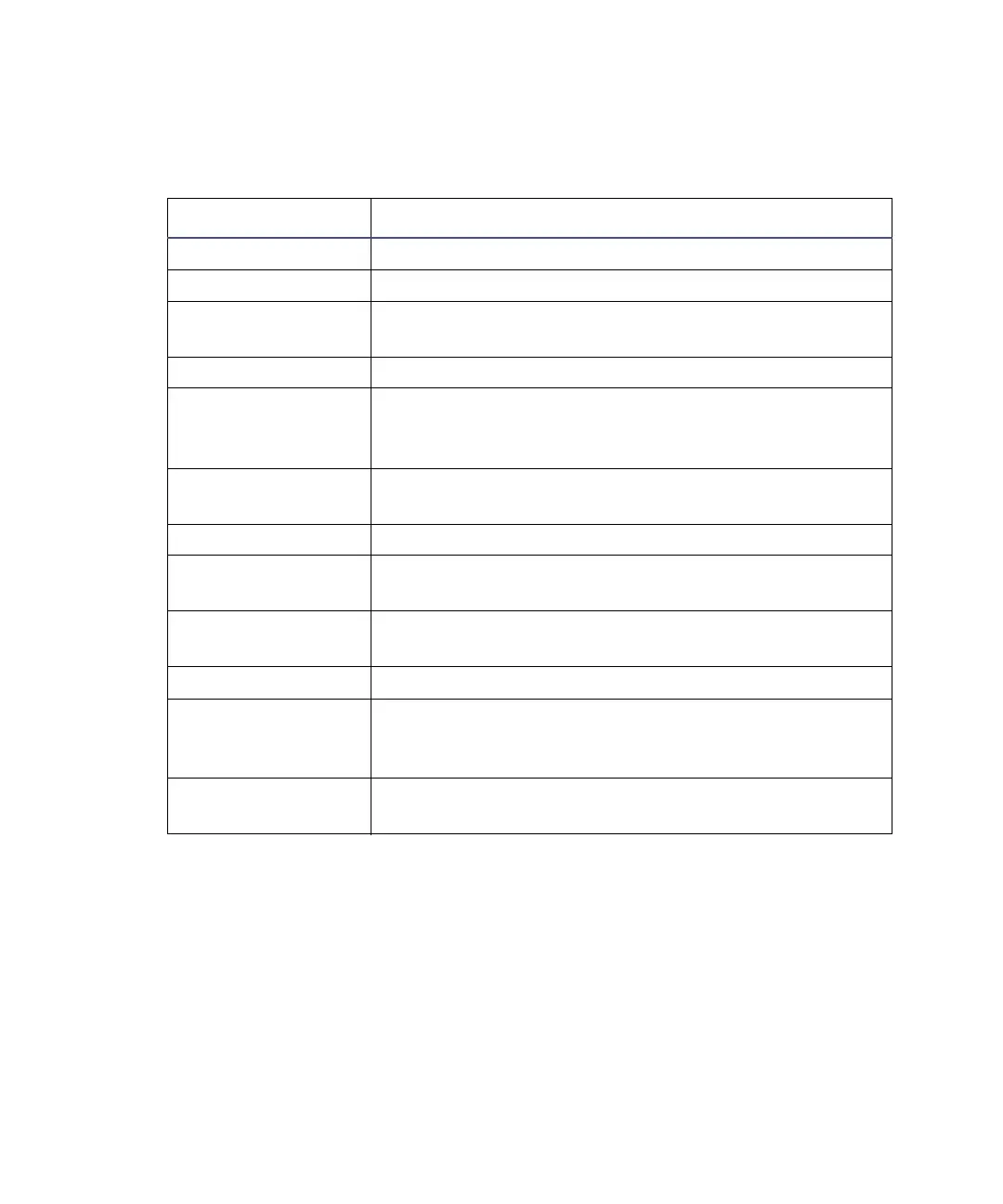

The table below lists diagnostic tests available through the extended test

routine.

Tip: If any tests fail during this procedure, contact Waters Technical Service.

Tools

The only tools required for the extended test routine are a jumper wire to

short various controller rear panel terminals and a screwdriver.

Extended test routine

Test Description

Keyboard test An echo of the key being pressed appears on the CRT.

LCD test Displays all characters in upper- and lowercase.

Stop Flow Input

test

Tests the Stop Flow input switch on the rear panel.

External Inject test Tests the INJ input terminal on the rear panel.

External Switches

and Hold Output

tests

Tests each of the four switch terminals and the Hold

output terminal on the rear panel.

Chart test Produces a 0- to 10-mV sawtooth waveform at the

chart terminals on the rear panel.

Sparge valve test Turns each sparge valve on and off in sequence.

Pump and solvent

valve test

Sets the pump to 1.0 mL/min (500-µL) or 4.0 mL/min

(100-µL) and switches the solvent valves periodically.

IEEE-488 test CPU reads and displays the setting of the IEEE-488

address switch on the rear panel.

RS-232 test Tests RS-232 communication.

12 VAC Fail test Operates the valves at a fast rate continuously

applying 12 VAC to the valves continuously. If this

condition is detected, the test passes.

Counter test Verifies that the valves cannot switch to a 50/50

condition.

Loading...

Loading...