54

START-UP

NOTE!

The last frequency reference (speed) vale set via the and

keys is saved.

If you wish to change this value before inverter enabling, change parameter

P121 (Keypad Reference).

NOTES:

(1) If the direction of rotation of the motor is not correct, switch off the

inverter. Wait at least for 10 minutes to allow complete capacitor

discharge and then swap any two wires at the motor output.

(2) If the acceleration current becomes too high, mainly at low frequencies,

set the torque boost (IxR compensation) at P136.

Increase/decrease the content of P136 gadually until you obtain an

operation with constant current over the entire frequency range.

For the case above, refer to Parameter Description in Chapter 6.

(3) If E01 fault occurs during deceleration, increase the deceleration time

at P101 / P103.

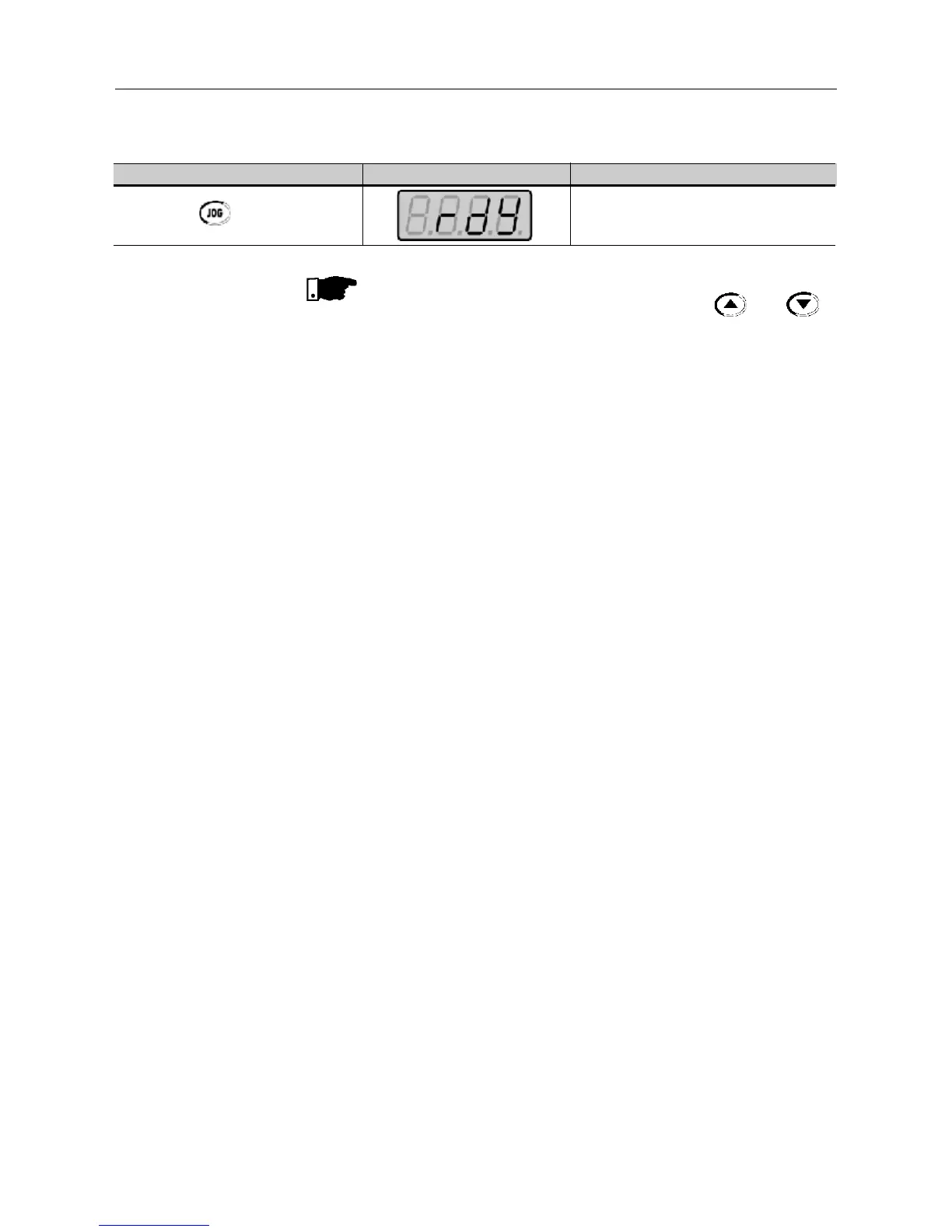

ACTION DISPLAY HMI DESCRIPTION

Release the key Motor decelerates down to 0 rpm

Loading...

Loading...