1

WEILER E1250

3-10

Maintenance

3

ALTERNATE BATTERY CHARGING PROCEDURE - CHARGING AS 12V SYSTEM

An alternate way to charge batteries in a 24 volt system is to charge each battery alone as a 12 volt battery. This

method is prefered by some. The steps for this process are detailed below:

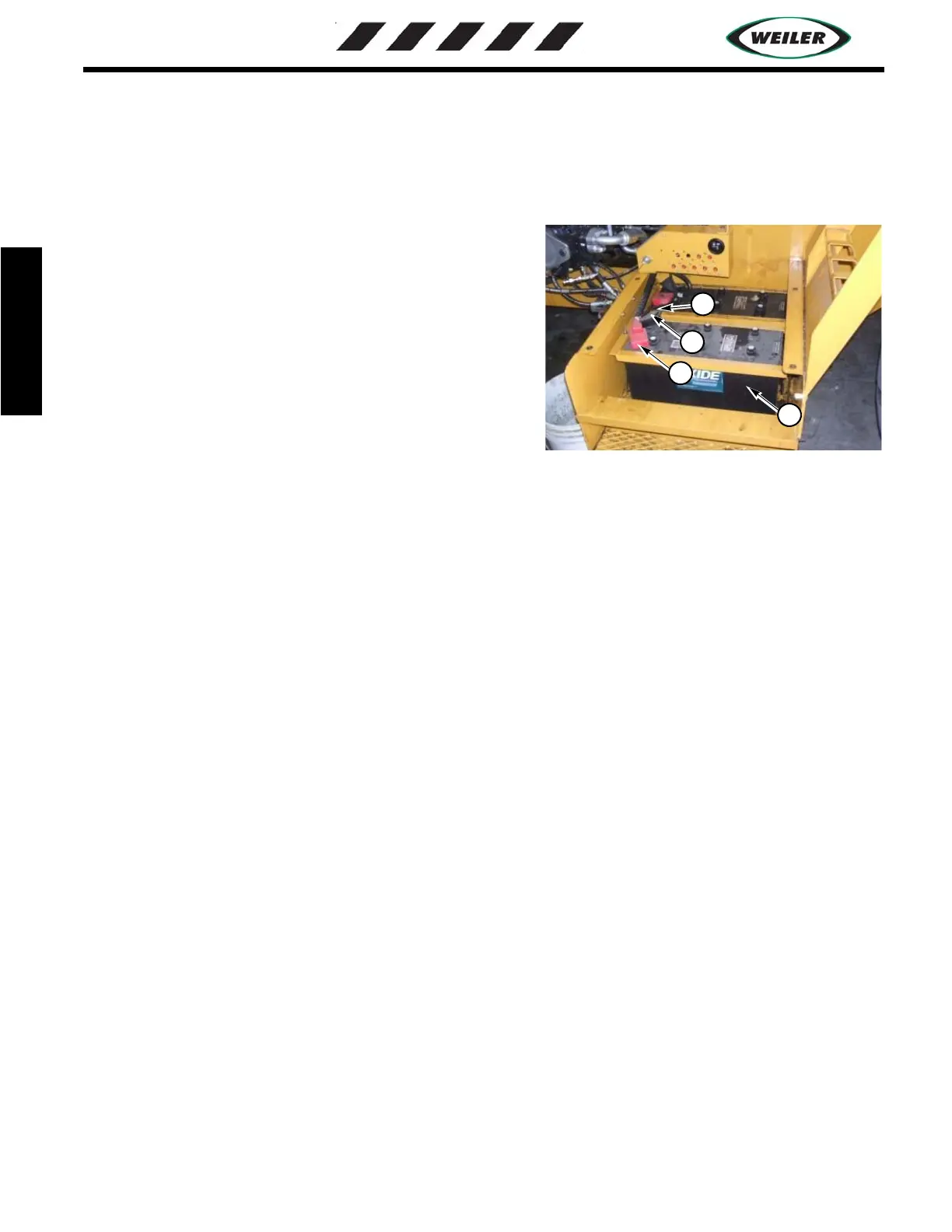

1. Turn off master switch (ground disconnect) and remove key.

2. Disconnect crossover cable (1).

3. Attach charging device (booster battery or battery charger) to

terminals of one battery at a time. Observe polarity, connecting

positive of the charging device to positive (2) of the battery (3)

and negative of the charging device to negative(4) of the battery

(3).

4. Allow battery time to charge. Longer charges at lower current

are better.

5. Disconnect the charging device, negative terminal before

positive terminal.

6. Repeat steps 2-5 for the opposite battery.

7. Turn master switch “on”.

8. Start engine using normal starting procedures.

WELDING

Proper welding procedures are necessary in order to avoid damage to the electronic controls and to the bearings.

When possible, remove the component that must be welded from the machine or engine and then weld the

component. If it is necessary to weld near an electronic part on the machine or the engine, temporarily remove the

electronic piece in order to avoid heat related damage. The following steps should be followed in order to weld on

the machine.

1. Turn off the engine.

2. Turn the ground disconnect OFF

3. Clamp the ground cable of the welder to the component to be welded. Place the clamp as close as possible to the

area to be welded. Make certain that the ground path will not travel through any bearing. Do not use the electrical

component’s grounding points as a ground for the welder. Use this procedure to prevent damage to the bearings,

hydraulics, electrical components, or other components of the machine.

4. Protect any wiring harnesses from weld splatter.

5. Use standard weld procedures for welding the materials together.

Loading...

Loading...