2-5

Operation

2

WEILER E1250

MACHINE OPERATION

1. Start and warm up machine using Engine Starting Procedure (page 2-2).

2. Lubricate the inside of the dump hopper and augers, the inside of the optional mixing hopper and augers, the

elevator chain, the conveyor chain and the inside of the optional hopper insert using spray down system. This will

make the surfaces contacted by the asphalt slick and make the machine easier to clean at the end of the paving job.

Verify all of the clean out doors are closed.

3. Position the machine in line with the paver as required and set the parking brake. Lower dump hopper to the

ground. Position the conveyor over the paver hopper or optional hopper insert. Position the operator console on the

desired side for operation, adjust mirrors, position the steering indicator as desired, and place hopper indicator chain

in correct position.

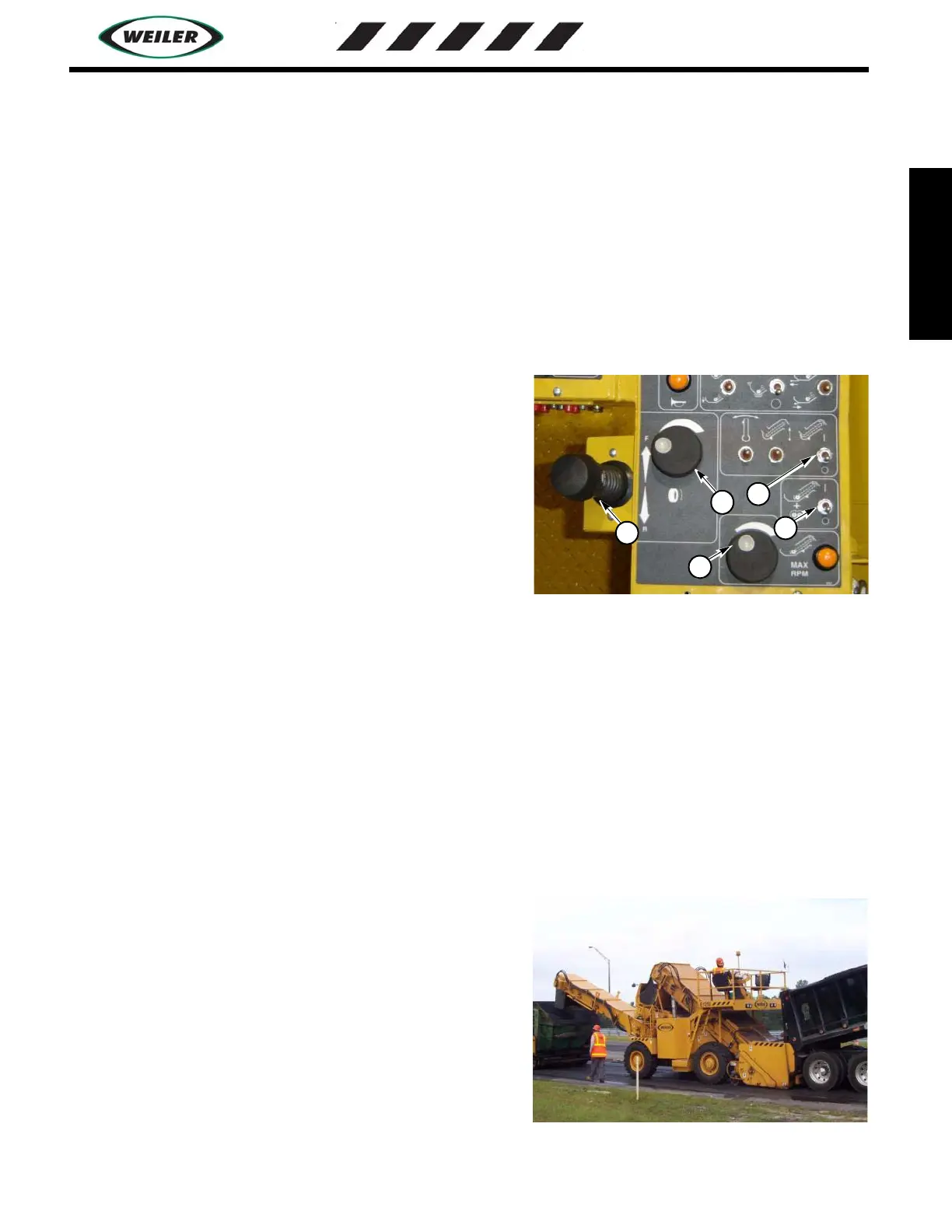

4.. Move two speed motor switch to low and move the creep

switch to the desired position, use low if slow paving speeds will

be used. Increase the engine throttle to high speed. Turn on the

conveyor chain (1) and then turn on the elevator chain and the

optional mix hopper (2). Use the elevator speed dial (3) to set the

chain speed at a slow speed.

5. Lower hopper baffle to keep material from overloading the

chain.

6. Back haul truck up to the hopper against the push roller.

Adjust push roller as necessary to allow truck to dump.

7. Slowly raise the box on the dump truck until material ‘slides’ against the tailgate. Hold box at that height and

unlatch tailgate, dumping material into the hopper of the E1250. If using a ‘flow boy’ truck or trailer fill the hopper

by unloading material.

IMPORTANT: While unloading the first few trucks on a job, meter the material very slowly using the hopper

baffle and a slow elevator chain speed. This will allow the steel parts on the machine to be lubricated and warm up

and make the material move easier through the machine. If material is unloaded too fast the elevator, conveyor or

optional remix hopper may stall. In the event of a stall, see Cleaning Stalled Machine.

8. Slowly open baffle to allow material to contact the combining augers and the elevator chain. Fill paver hopper or

optional hopper insert to near capacity. The paver will begin to auger out material out at this time in preparation for

paving.

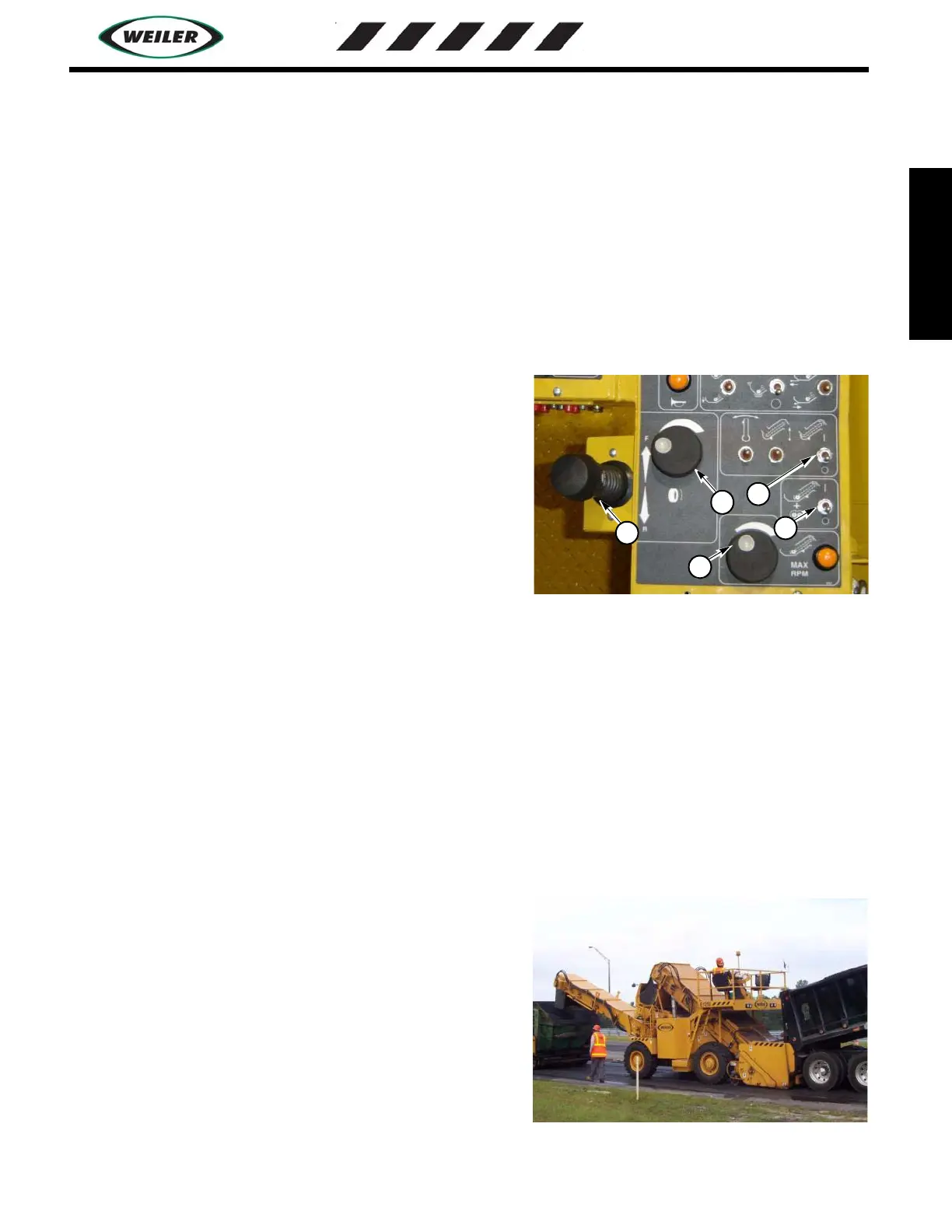

9. When hopper is full enough and the paver is ready to begin

moving, release the park brake and begin traveling at the speed

the paver is moving using the propel lever(4). Adjust ground

speed using the ground speed dial (5) to keep the conveyor over

the hopper of the paver.

Loading...

Loading...