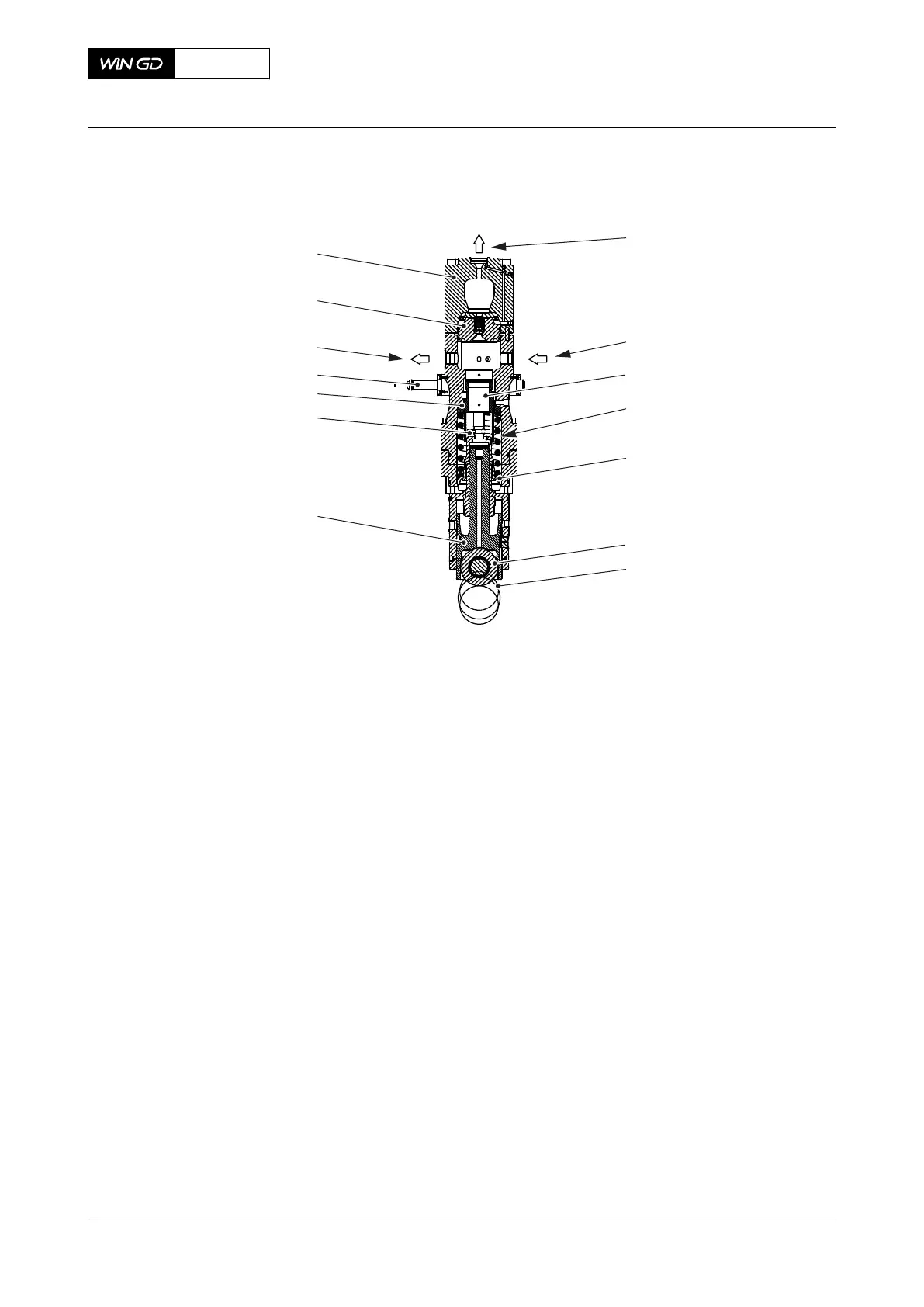

Fig 5-28 Fuel pump - cross section (example)

001

002

003

004

005

006

007

014

013

012

011

010

009

008

Legend

001 HP fuel to fuel rail 008 Guide piston

002 Fuel inlet 009 Driver (of pump plunger)

003 Pump plunger 010 Regulating sleeve

004 Compression spring 011 Toothed rack

005 Bottom spring carrier 012 Fuel outlet

006 Roller 013 Non-return valve

007 Cam 014 Pump cover

5.5.3.2 Lubrication

Engine lubricating oil, which flows through the lubricating oil inlet into the bottom housing,

lubricates the fuel pump.

Leakage fuel lubricates the pump plunger (003). The leakage fuel and the engine lubricating oil

from the regulating sleeve (010) flows through the drain bore. This mixture then flows into an

internal bore in the housing of the fuel pump unit.

5.5.3.3 Operation with an unserviceable fuel pump

If a fuel pump is unserviceable (eg the pump plunger cannot move) or the HP fuel pipe is broken

(between the fuel pump and the fuel rail) the fault must be repaired immediately. If the fault cannot

be repaired, it is possible to cut out the unserviceable fuel pump. Related to the number of installed

fuel pumps, there are limits of operation.

X92-B

AA00-5556-00AAA-043A-A

Operation Manual Fuel pump

Winterthur Gas & Diesel Ltd.

- 167 - Issue 002 2021-11

Loading...

Loading...