11 Malfunctions

This explains what action to take in case of malfunctions. The tables provide information about possible

causes and notes on remedial action. Contact the Winterhalter service technician if you are unable to rectify

the fault yourself.

DANGER! Risk of fatal injury due to live components!

Disconnect the machine from the mains and check for the absence of voltage before starting

any electrical work on the machine.

Do not open any machine covers or machine components if you would require a tool to do so.

Electric shock hazard.

Have all work on the electrical system performed by a Winterhalter service technician.

The machine must be disconnected from the electrical mains first.

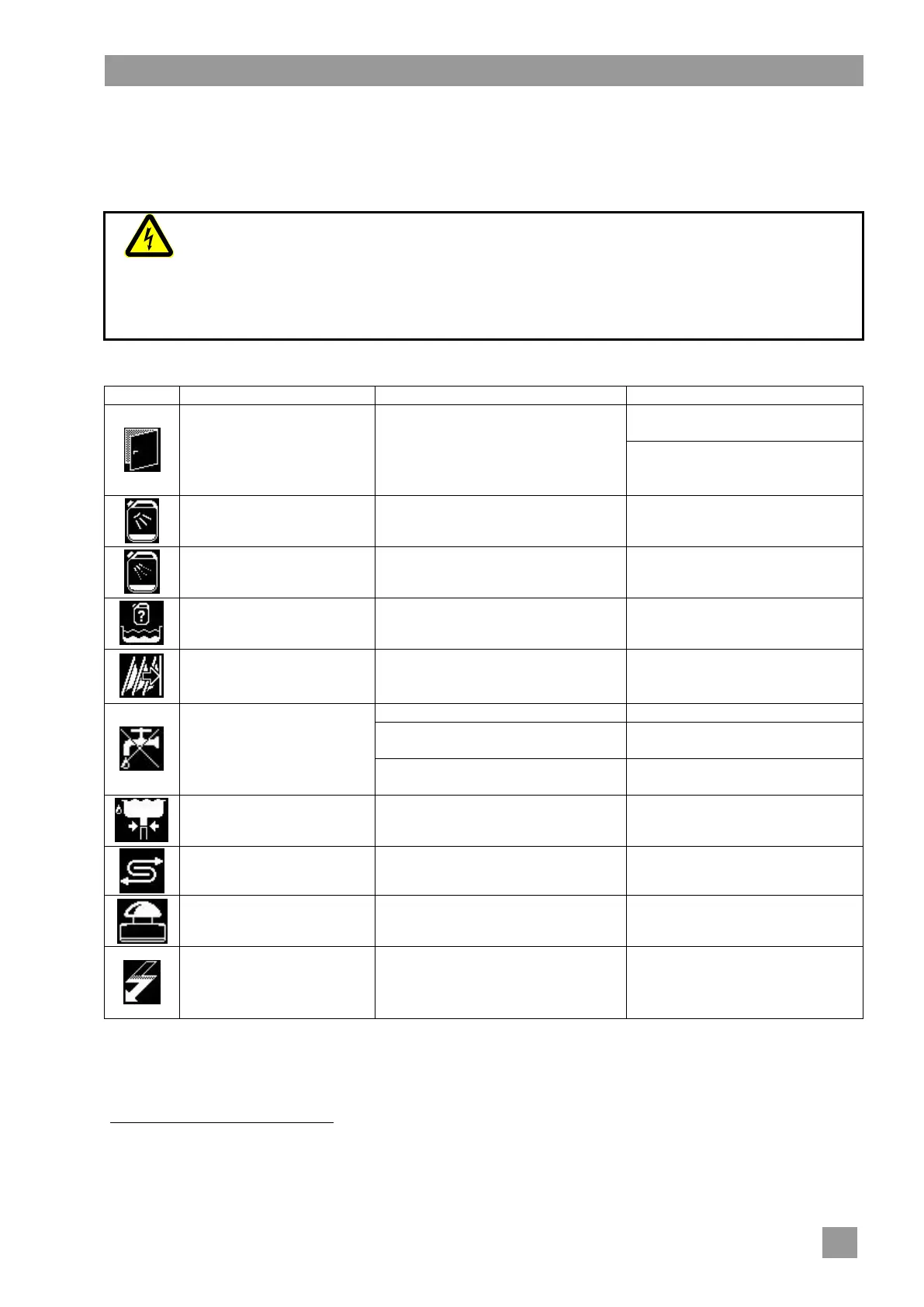

11.1 Malfunctions; display by symbols on the screen

MTF: Insert the panels at the

end of the loading/unloading

zones.

Detergent drum is empty

1

Rinse aid drum is empty

1

Crockery / washing racks are

backing up at the end of the

conveyor belt or the outfeed table

Release the stop switch (remove

the crockery, washing rack)

Debris filter in dirt trap is blocked

Remove the debris filter and

clean it ( 8.2)

Solenoid valve defective or

blocked; feed pump defective

See RoMatik 420 device

documentation

EMERGENCY OFF switch

pressed

Release the EMERGENCY OFF

switch

Energy optimisation system in the

building switches individual

electrical loads (heating elements)

off.

Wait until the energy

optimisation system in the

building switches itself off

This is only displayed if the container has a container empty indicator that is connected to the machine.

This is only displayed if the dosing equipment has a conductivity detection function. The fault must be

transferred from this dosing equipment to the machine electronic control unit.

This is only displayed if the error output on the RoMatik 420 is connected to the MTR / MTF.

This is only displayed if the machine is connected to an energy optimisation system.

Loading...

Loading...