Maintenance

17.10.2019 63 / 96

6.2 Maintenance schedule

Caution - material

Risk of damage to the ProofMaster due to insufficient

servicing of the compressor!

Failure to service the compressor may result in contamination of the

compressed air by oils harmful to the ProofMaster.

• Service the compressor as specified in the manufacturer's

documentation.

• Make sure to comply with the maintenance cycles specified in the

following maintenance schedule.

ð Non-compliance will void the warranty.

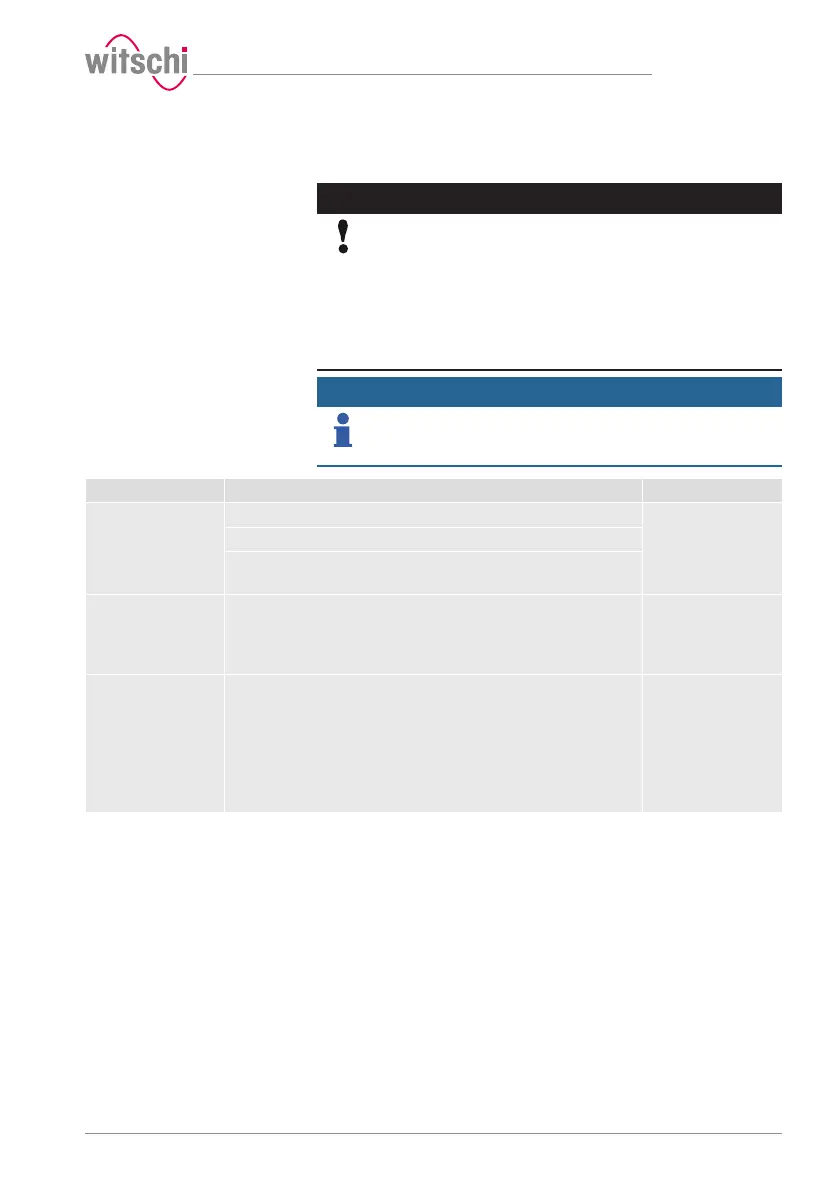

Info

The following maintenance schedule is intended for the

operator of the ProofMaster.

Maintenance of the ProofMaster does not require a specialist technician.

Interval Maintenance task Personnel

Daily Clean the seal with a dry microfibre cloth. Operator

Check that the compressed air hose is secure and in good condition.

Make sure that the bell cover is closed at the end of the day. See

Switching off the device [}Page 36].

Calibration as per the

calibration

instructions on the

device

Have the ProofMaster recalibrated. To do so, contact the point of

sale. See Technical support [}Page 7].

The deformation sensor can be sent individually or installed with the

ProofMaster. See Replacing the deformation sensor [}Page 64].

Customer service

After 200,000tests or

every 8 years, at the

latest

An inspection must be carried out on the ProofMaster. The message

"Inspection required. Call Witschi service" appears when starting the

ProofMaster. To do so, contact the point of sale. See Technical

support [}Page 7].

Comment

The number of tests since initial commissioning can be found in the

menu Settings > Info > Operating information.

Customer service

Loading...

Loading...