22

3062547_201802

16 Oilconnectioninthesingleline

system

Secure the lter vent combination with the integrated shut-off valve and retainer to the

positions provided for this. In doing this, the oil hose should be a max. of 90 cm outside

of the housing during rear wall implementation. The lter vent combinations must be

freely accessible once installed.

Onlyuselterinsertsmadeofsinteredplasticwith25-40μmto

preventcontaminationoftheoilnozzlewithintheserviceinterval.

Contaminatedoilnozzlesleadtotheboilerfailing.

The system must be connected as a single line system. A lter/air vent valve combination

with an integrated shut-off valve from the Wolf product range must be installed.

Oldertwo-linesystemsmustbeconvertedtosinglelinesystems.Two-

linesystemsleadtoacceleratedoilageingandthepenetrationofair

intotheoil.Theyarenolongerinlinewiththelatesttechnology.

Onlymaterialsthataresuitableforoillinesshouldbeused.Inthecase

ofcopperpipes,onlymetalliccompressionttingoliveswithsupport

sleevesarepermissible.Theyareareliablemeansofpreventingairintake.

In accordance with TRÖl, the oil supply shall be checked for its perfect

condition and proper installation and a nal tightness check shall be carried out.

This inspection shall be performed:

• Before commissioning

• For underground oil lines, before they are covered and

• after work on the oil lines (except for oil lter changes)

Inordertopreventdamagetotheoilpump,thefueloilmustbesupplied

tothelterusingasuitablemanualpump.

Thetemperaturemustnotfallbelow+5°C.Externaltanksmusthave

supplementaryheatingfacilities.Theoillinesmustbeinstalledwhile

thesystemisisolatedfromtheelectricalsupplyinordertoavoidleaks.

Contaminantscanleadtosystemdamage.Theoillinemustbeushed

priortocommissioning.

The maximum possible suction line length results from the pressure losses on the

pipes and ttings and the inlet height. All vertical and horizontal pipes are identied as

line lengths.

The following table can be used for sizing. When sizing the line lengths, the lter, non-

return valve and six 90° bend resistances are already taken into account.

Installing suction lines of a max. of 40 m is recommended.

The maximum permitted negative pressure in the suction line is 0.3 bar.

Device

Throughput

Inner line

Ø

Inlet height H (m)

kg/h mm +4 +3 +2 +1 0 -1 -2 -3

COB-15

COB-20

COB-29

Up to 2.5 4 40 40 40 40 40 35 25 13

COB-40 Up to 3.7 4 40 40 40 38 29 22 15 9

Floating or raised suction shall be used, if permitted.

Floating suction is not permitted for underground oil tanks or for oil tanks for which a

special draw-off device is prescribed by the manufacturer.

Oil lines that are too large may lead to operating faults caused by trapped air. The oil

supply must therefore be designed with an interior line diameter of 4 mm.

Oillter/oillineinstallation

Note

Note

Note

Maximumlinelengthsinsingleline

systems

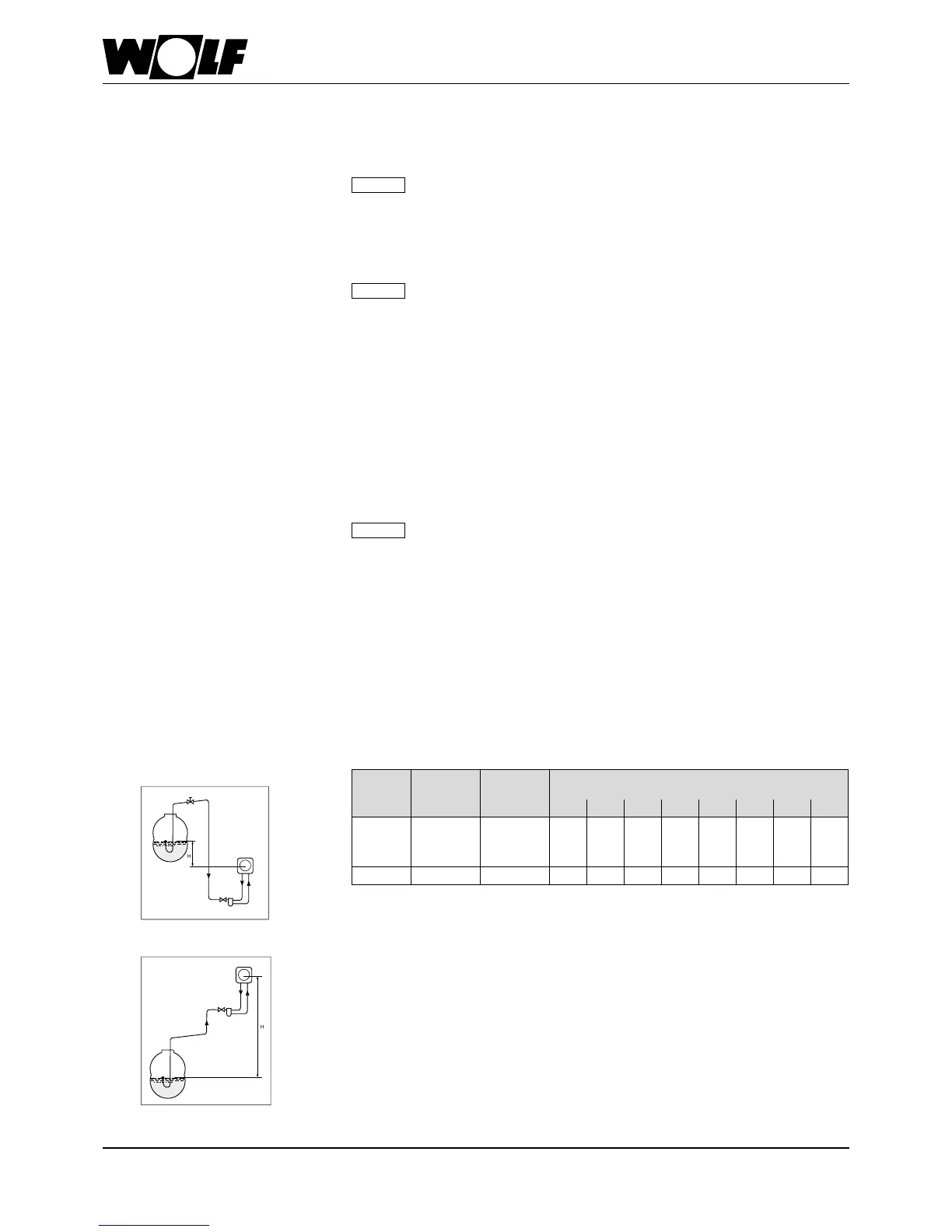

Floating air

extraction

Oil pump,

burner

+

Anti-trap valve

Fig.:

Single line system with pump lower than tank

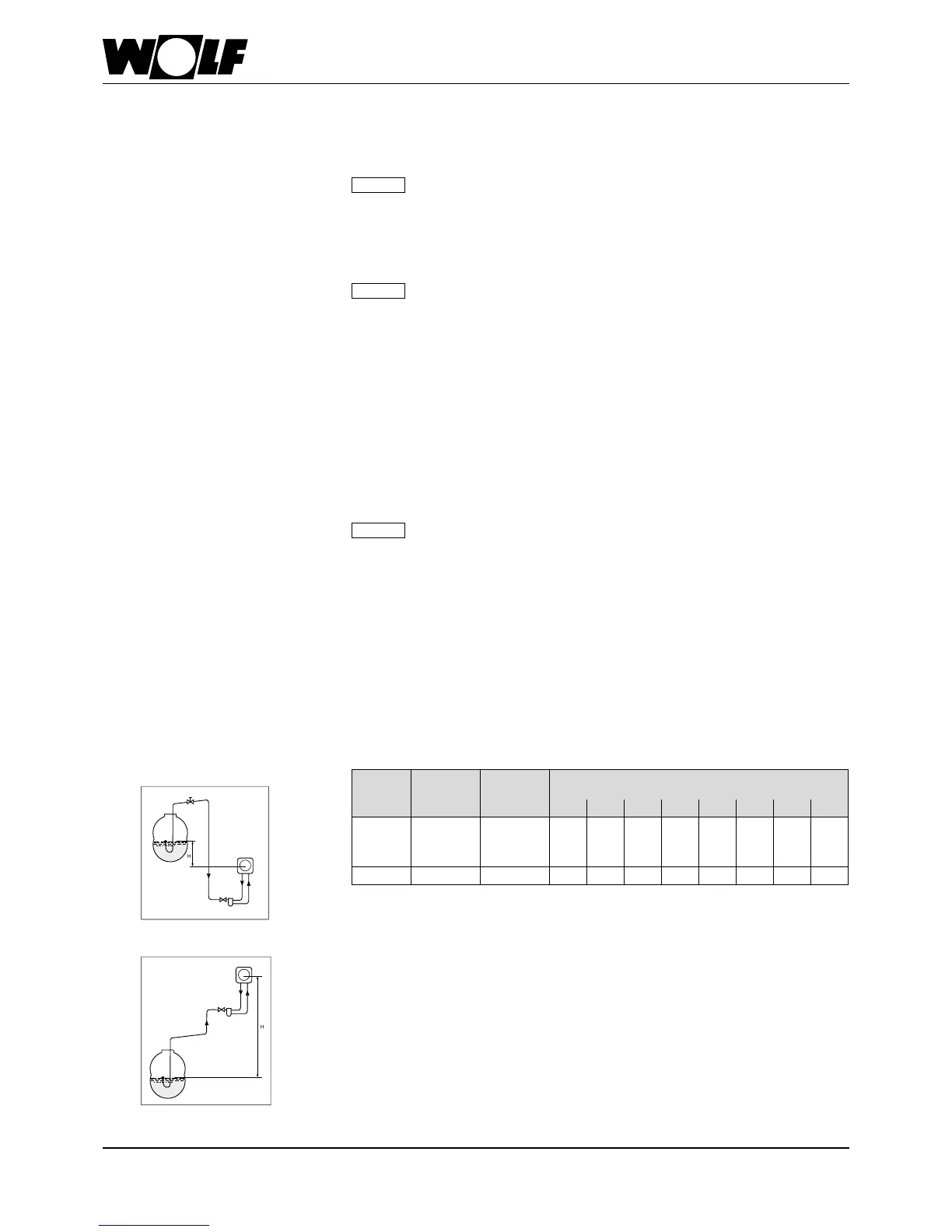

Fig.:

Single line system with pump higher than tank

Oil pump,

burner

Floating air

extraction

-

Loading...

Loading...